Injection molding is a widely used manufacturing process in various industries. One important aspect of injection molding is the clamping system, which is responsible for securely holding the mold in place during the injection process. Traditional clamping systems often require time-consuming mold changes and modifications. However, with the advent of magnetic platens, the injection molding industry has experienced a significant technological advancement.

Efficiency Mold Change of Magnetic Platens

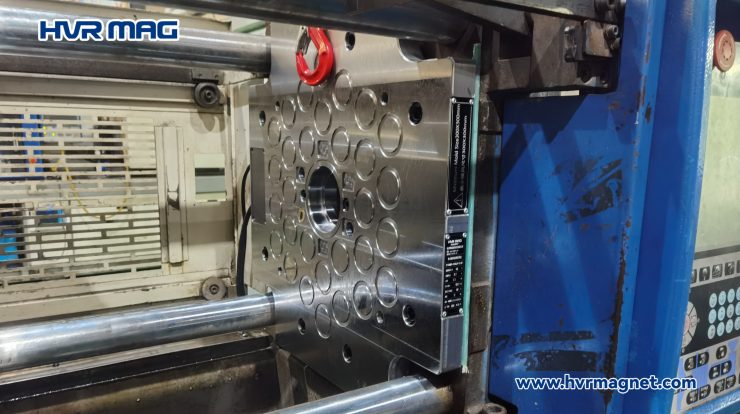

One of the main advantages of magnetic platens is their ability to facilitate quick and efficient mold changes. By adopting electro permanent magnetic technology, these clamping systems can change molds in as little as 3 minutes. This remarkable speed ensures minimal downtime and maximizes production efficiency.

Versatility and Adaptability

In addition to their quick mold change capabilities, they offer a high level of versatility and adaptability. They apply to most molds, regardless of size or complexity. This means that companies can quickly adapt to different production requirements without facing significant delays or costs associated with mold modifications.

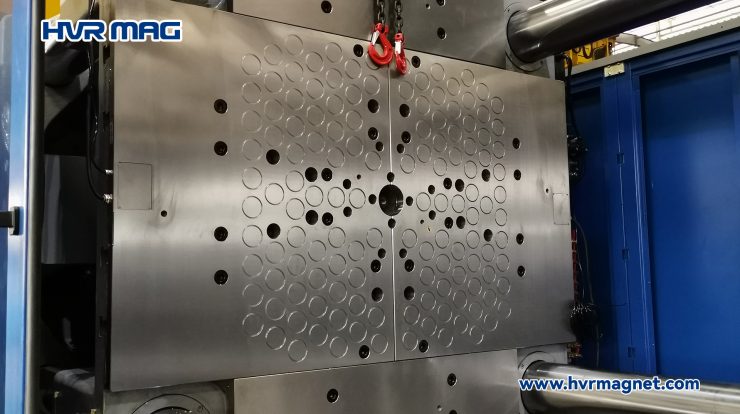

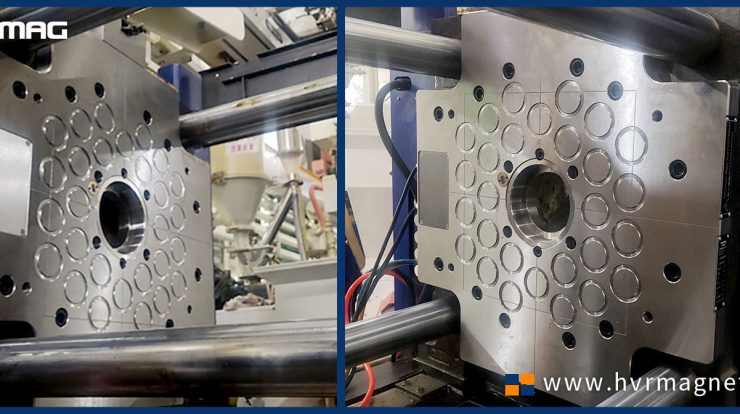

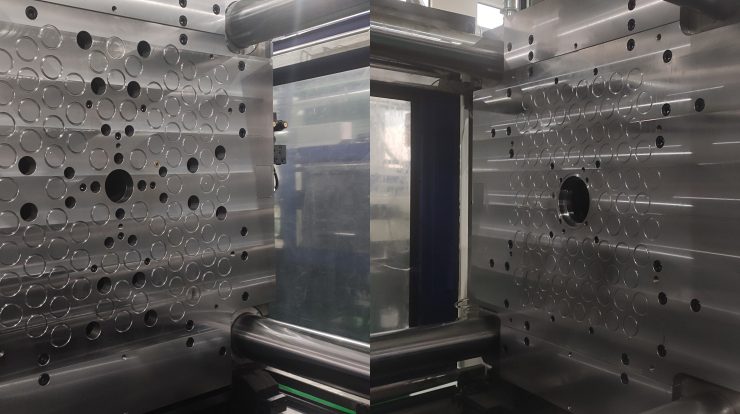

Application of Magnetic Platens

These are two sets of magnetic platens specifically designed for a 100T injection molding machine in the wastewater treatment industry. Despite the smaller size of the molds used by customers, these platens were immediately implemented, eliminating the need for any mold transformations. This swift deployment highlights the applicability and ease of use that magnetic platens offer, demonstrating their suitability for a wide range of circumstances.

Enhanced Productivity and Cost Efficiency:

The usage of magnetic platens also contributes to enhanced productivity and cost efficiency in the wastewater treatment industry. The ability to quickly change molds translates into shorter lead times, allowing companies to meet the demands of a rapidly changing market. Moreover, the elimination of mold transformations significantly reduces production costs. Traditional clamping systems often require additional expenses for modifying molds, which can be both time-consuming and expensive. They eliminate these extra costs, making them a cost-effective and practical choice for companies in the wastewater treatment industry.

Conclusion

Remember, magnetic platens are not only about quick mold changes; they represent a transformative technology that enhances efficiency, productivity, and cost-effectiveness. Whether you operate in the wastewater treatment industry or any other field that employs injection molding, they can revolutionize your production processes. Embrace this innovative technology and stay ahead of the competition in today’s dynamic manufacturing landscape. For more information, please contact HVR MAG at export@hvrmagnet.com.