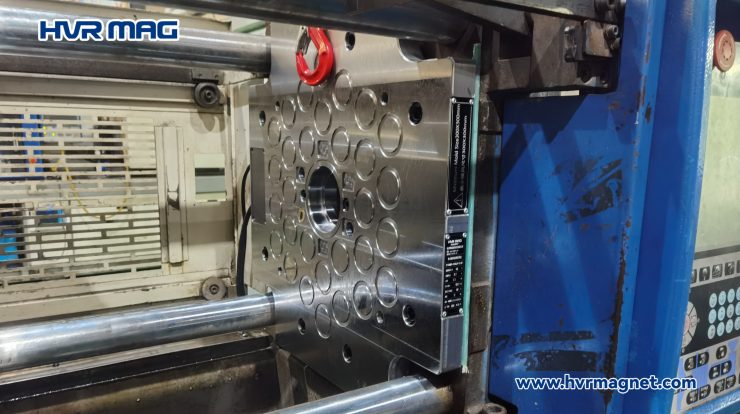

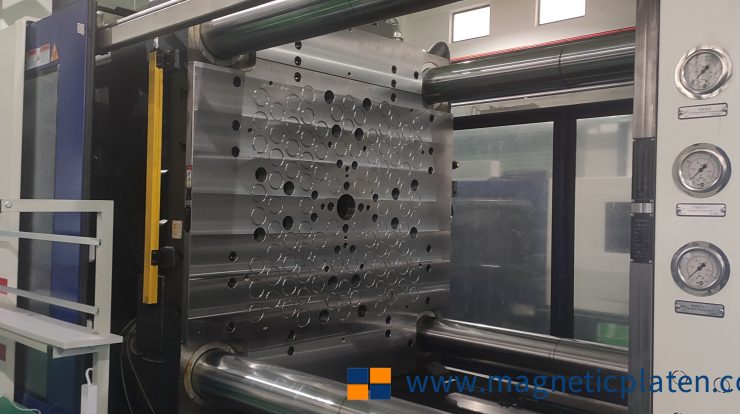

Advantages of Magnetic Platens with Circular Poles

Why do some magnetic quick mold change systems use magnetic platens with circular poles? This article will answer this question. Enhance the Versatility of Magnetic Platens in Mold Size Accommodation…

Magnetic Quick Mold Change System Change Mold in 7 Steps

In the injection molding process, mold changes can eat up valuable production time. That’s where magnetic quick mold change system comes in. Let’s delve into its seven-step process: Quick Mold…

What is SMED and Equipment for Quick Mold Change

What is SMED? SMED, which stands for Single-Minute Exchange of Die, is a groundbreaking lean manufacturing technique that originated in Japan in the early 1950s. SMED aims to minimize setup…

Understand the Applicability of Magnetic Platens

Injection molding is a widely used manufacturing process in various industries. One important aspect of injection molding is the clamping system, which is responsible for securely holding the mold in…

Magnetic Platen: Making Injection Molding More Eco-Friendly

Injection molding machines consume a considerable amount of energy during operation. Implementing energy-efficient equipment, optimizing production processes, and using energy-saving technologies can significantly reduce the energy consumption associated with injection…

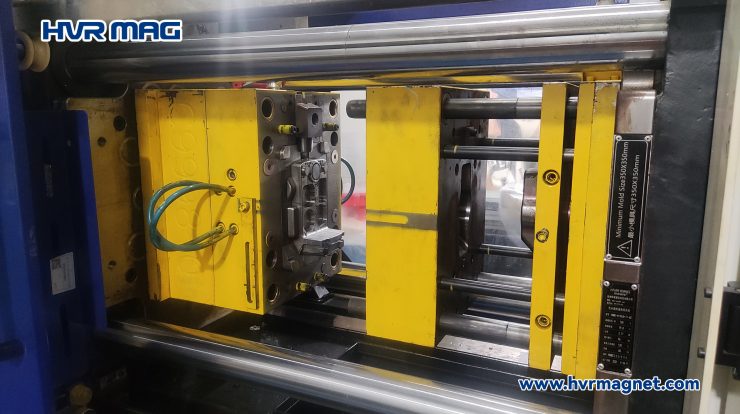

Understand How Injection Molding Machine Uses Magnetic Clamping System

Magnetic clamping system is essential in the injection molding industry, offering numerous benefits despite certain operational challenges. If your company has not yet adopted a magnetic clamping system, it is…

Types of Mold Clamping for Injection Molding Machine

When it comes to injection molding machines, the clamping mechanism plays a crucial role in securely holding the mold during the injection process. Three commonly used clamping methods are hydraulic…

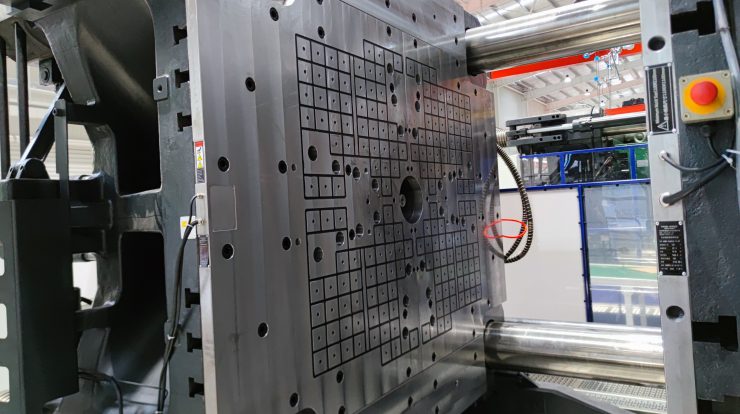

Magnetic Quick Mold Change for Automotive Parts Injection Molding

These days in automotive injection molding, many are searching for more efficient mold change system. It should also be adaptable to the industrial intelligent system and advanced factory layout. Check…

Magnetic Quick Mold Change Knowledge: for You to Help

This is a passage to popularize the magnetic quick mold change knowledge. Nowadays, small batches and multi-species orders lead to frequent mold changes in the injection molding line, which is…

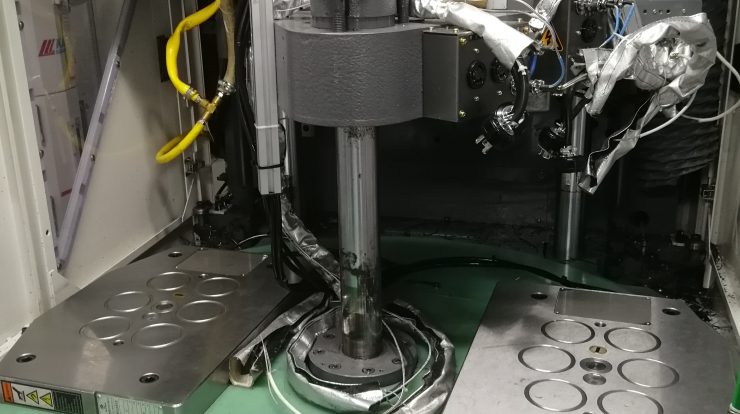

Magnetic Mold Clamping Solution for Vertical Injection Molding Machine

Today I’d like to share with you this application case of small tonnage magnetic mold clamping solution for vertical injection molding machine.