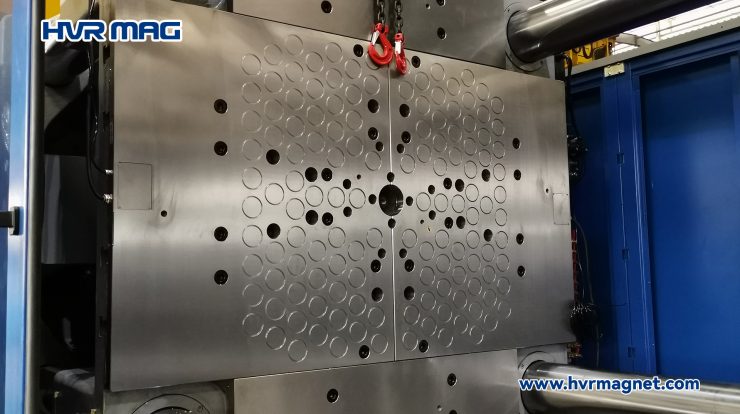

HVR Mag‘s commitment to providing reliable and secure solutions is reflected in the comprehensive safety features integrated into our magnetic platens. Here, we discuss the various safety measures employed to guarantee the safe operation of the HVR Magnetic Quick Mold Change System.

1. Mold Contact Detection

Before magnetization, the mold must be in a tightly closed position. Interlock controls ensure that any foreign objects or gaps between the mold and the magnetic platen are detected, preventing insufficient magnetization that could compromise safety during operation.

2. Magnetic Flux Detection in Quick Mold Change System

Real-time monitoring of magnetization strength ensures that only when the magnetic flux reaches a safe level, the system signals successful magnetization. Any deviation in magnetic flux during operation triggers immediate fault alarms, halting the automatic operation of the injection molding machine.

3. Distance Sensing

Sensors are utilized to detect the distance between the mold and the magnetic platen. Magnetization or demagnetization operations are only allowed when this distance is less than 0.2mm, ensuring safe and effective mold attachment. Any unexpected increase in distance during operation prompts fault signals and halts machine operation.

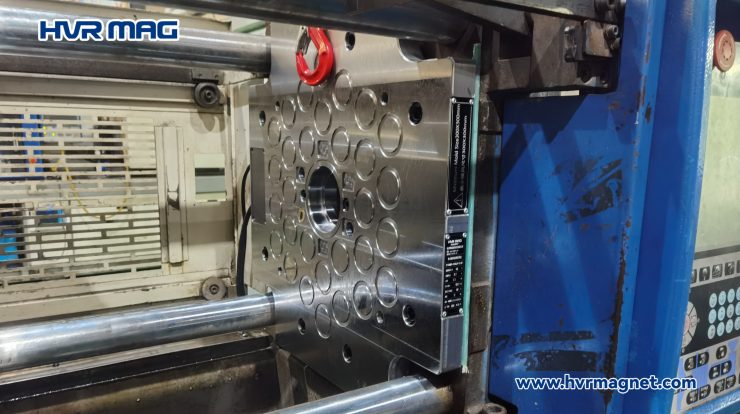

4. Temperature Monitoring in Quick Mold Change System

To prevent demagnetization due to overheating, temperature sensors continuously monitor the temperature of the magnetic platen. If the temperature exceeds preset limits, the control system issues an alarm and stops the injection molding machine automatically.

5. Magnetization Current Detection

During magnetization or demagnetization actions, the control system monitors the pulse current to ensure it meets the required specifications before signaling successful operations.

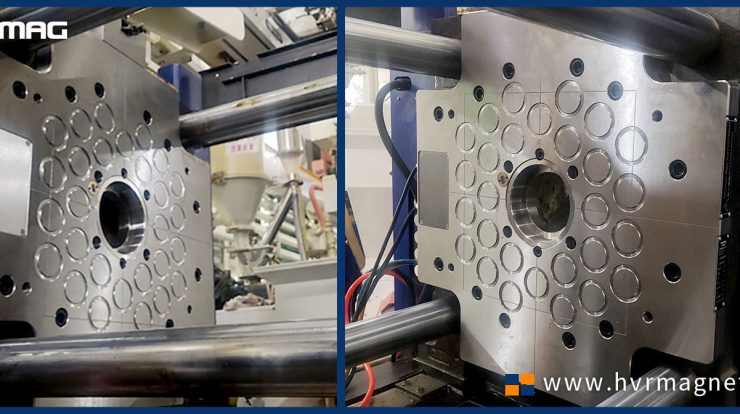

6. Mold Misalignment Detection

Sensors continuously monitor the position of the mold during injection molding. Any slight movements trigger fault signals, preventing potential accidents, and stopping machine operation.

7. Key Switches for Mode Transition

Mode transitions between mold change and injection molding are controlled via key switches. Demagnetization operations require simultaneous activation of two buttons to prevent accidental operations.

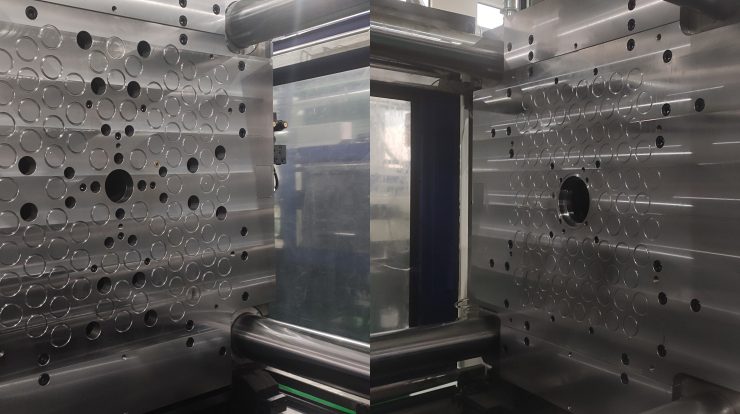

8. Safety Door Closure Detection

During mold change, safety doors must remain closed to ensure operator safety.

9. Interlock Control with Injection Molding Machine

Interlocking controls ensure that the injection molding machine only operates when all safety checks are passed, and the system is in injection mode. Any fault signals or mode switches immediately halt machine operation.

10. Leakage Protection of Magnetic Quick Mold Change System

The control system includes leakage protection to promptly disconnect power in case of electrical faults, preventing potential accidents. During injection molding, the main power circuit to the magnetic platen is completely disconnected.

11. Additional Safety Features

Optional safety devices such as limit blocks and safety chains can be added to further enhance mold security, ensuring no possibility of detachment under any circumstance.

Quick Mold Change System Safe Insurance Conclusion

In conclusion, the safety insurance of magnetic platens in HVR Magnetic Quick Mold Change System is comprehensive and robust, incorporating multiple layers of protection to safeguard operators, equipment, and processes. By integrating advanced safety features, these systems ensure efficient operations without compromising on workplace safety. For more information, please contact us at export@hvrmagnet.com