With the shortening of plastic product life cycle and the increasing demand of customization, forcing factories to adapt to a mode of production with less quantity and more variety, especially in the automotive industry. However, the traditional mold change system greatly affects the production efficiency. In this trend, the magnetic clamping system which significantly shorten mold change time, have approached to the scene view of human gradually. TECNOMAGNETE, an Italy company, was the first manufacturer to introduce magnetic clamping system. HVR MAG is also one of the earliest manufacturers to develop and produce magnetic quick mold change system and has been developing for more than 10 years in this industry.

Tecnomagnete’s Quad-Press system is a combination of two magnet technologies. The 51-mm-thick platen design is based on a square-pole technology utilizing a 3 x 3 in. magnetic “cell” composed of four steel cubes. The top surface of the steel cubes are the contact surface of the magnetic platen. Four sides of the cube are surrounded by rare-earth magnets of neodymium-iron-boron alloy. On the bottom of the steel cube is a layer of aluminum-nickel-copper (alnico) magnet and a copper coil. The neodymium alloy never changes its polarity, but the alnico changes its polarity in response to electric current in the coils underneath the steel cube. When the current is turned off, the alnico retains its new polarity.

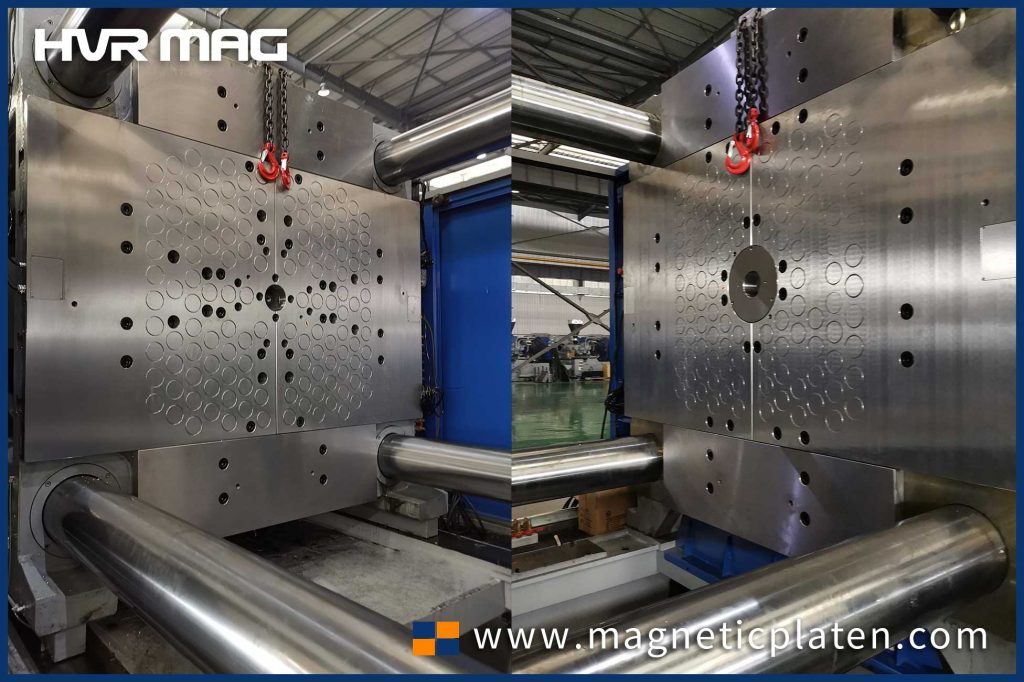

HVR MAG has a different approach. HVRMAG uses round-pole, round-type alnico magnets, with the north and south pole on each end. A coil wraps around each end of the magnet. Neodymium-iron-boron magnets are wrapped around each pole. The magnetic platen is about 35 mm thickness (less than 200 ton injection machine), reportedly the thinnest on the market, saving machine daylight. It contains the magnet and coil. The coil is activated with 10 to 100 amps for one-third of a second.

Although the design is different, the result is same and the best solution for quick change mold. HVR MAG magnetic clamping systems win the approval of more and more customers.