Are Magnetic Quick Mold Change Systems Recyclable?

In the fast-paced world of injection molding, efficiency and productivity are key factors for success. Magnetic quick mold change systems have emerged as a cutting-edge solution to streamline the mold…

Check If Magnetic Platen Is Compatible for Your Business

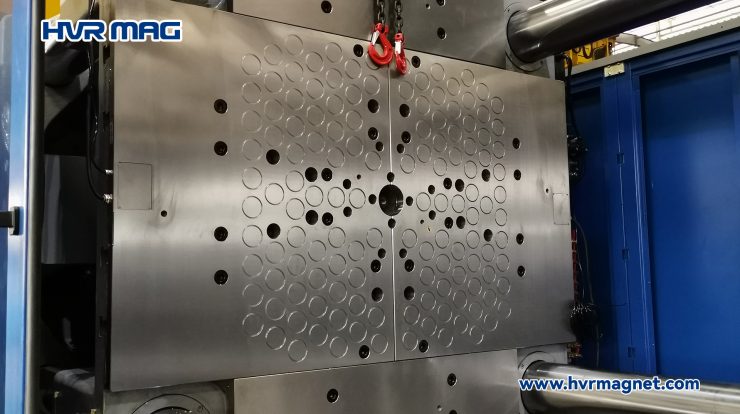

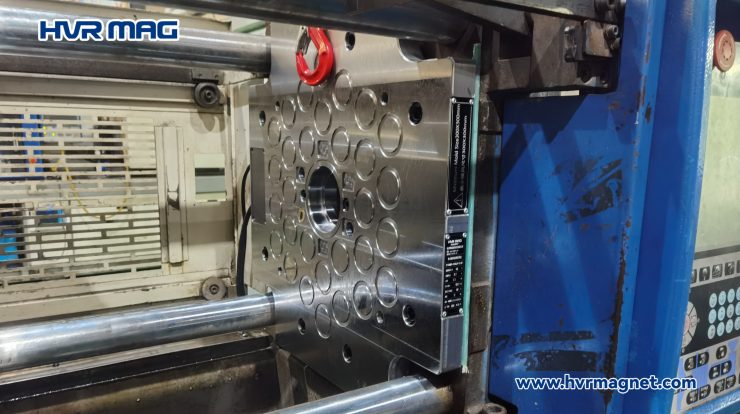

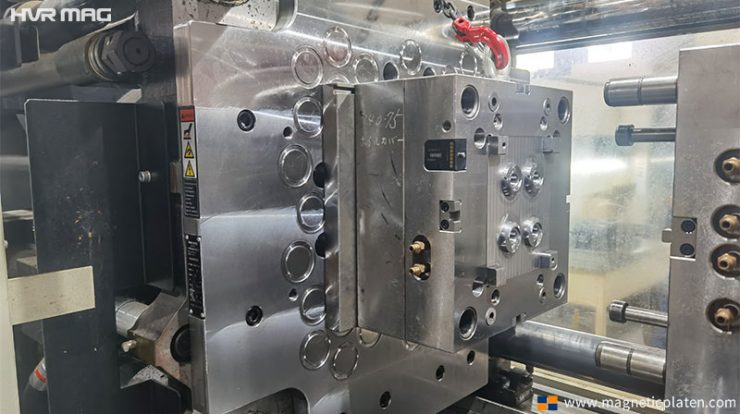

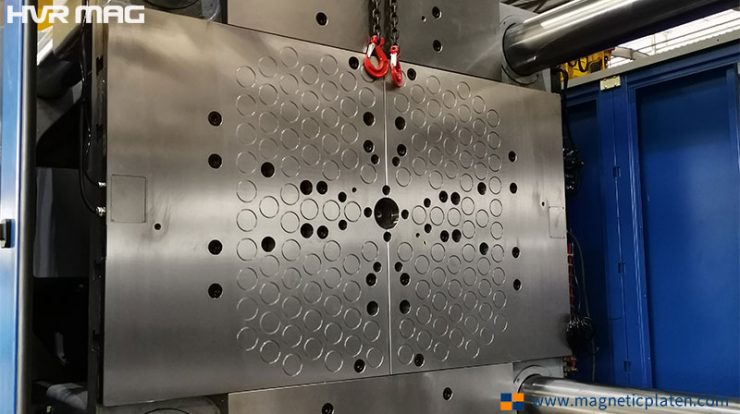

What is magnetic platen? Magnetic platen, also known as electro permanent magnetic mold clamping system, is often used in injection molding applications. It offers the advantages of quick mold changeover…

Understand the Applicability of Magnetic Platens

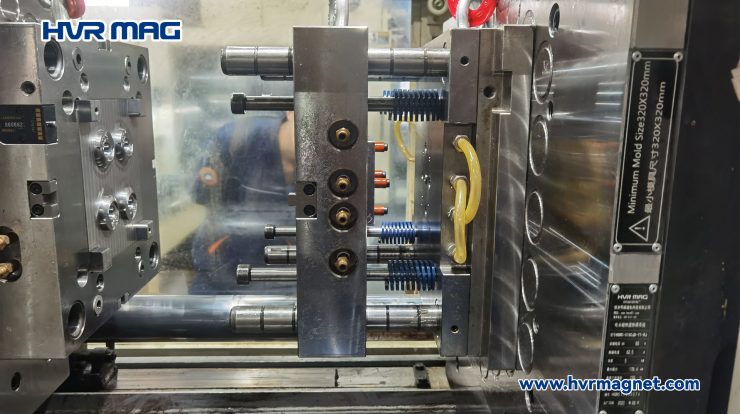

Injection molding is a widely used manufacturing process in various industries. One important aspect of injection molding is the clamping system, which is responsible for securely holding the mold in…

Magnetic Clamping Systems for Two-Color Molding Machine

A two-color injection molding machine is specifically designed to produce molded parts using two different colors or materials in a single injection molding cycle. This type of machine has the…

Injection Molding for Medical Devices: Keep Clean with Magnetic Platen

Injection molding is a widely employed manufacturing process for producing plastic components, and it is well-suited for the production of medical devices due to its ability to provide high precision,…

How Do Magnetic Platens Work Under High Temperature?

Magnetic clamping system has emerged as a useful tool to enhance efficiency and accuracy in injection molding process. This system comprises two sets of electro permanent magnetic platens, with one…

Understand How Injection Molding Machine Uses Magnetic Clamping System

Magnetic clamping system is essential in the injection molding industry, offering numerous benefits despite certain operational challenges. If your company has not yet adopted a magnetic clamping system, it is…

Will Clamping Method Affect the Quality of Product?

Plastic injection molding is a highly versatile process to produce complex shapes and parts with a high degree of accuracy and consistency. Injection molding machines have varies of size and…

The Best Way of Mold Clamping: Magnetic Plates

Mold clamping is very important for injection moulding machines. Currently, the best way of mold clamping is to use a magnetic plate.

The trend of quick mold change systems in 2023

As we all know, the traditional mold change methods are too inefficient to follow the trend. However, quick mold change system brings a lot of convenience to the mold industry….