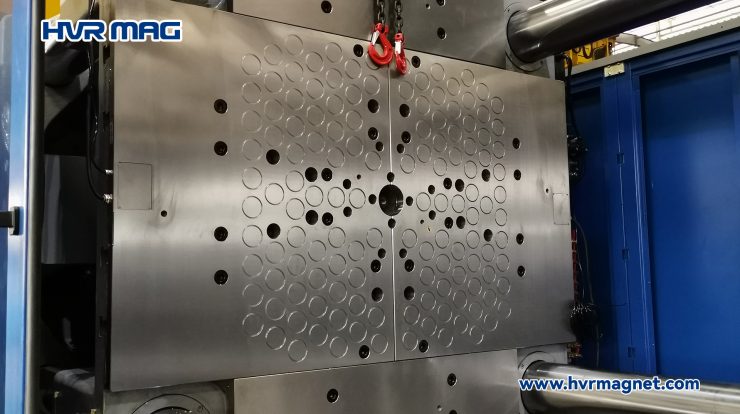

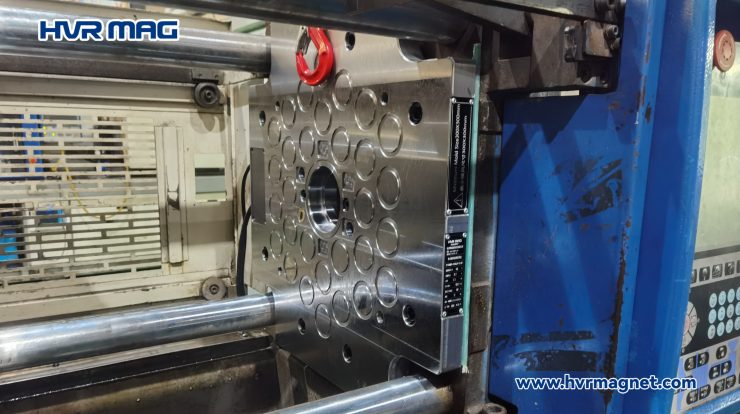

Advantages of Magnetic Platens with Circular Poles

Why do some magnetic quick mold change systems use magnetic platens with circular poles? This article will answer this question. Enhance the Versatility of Magnetic Platens in Mold Size Accommodation…

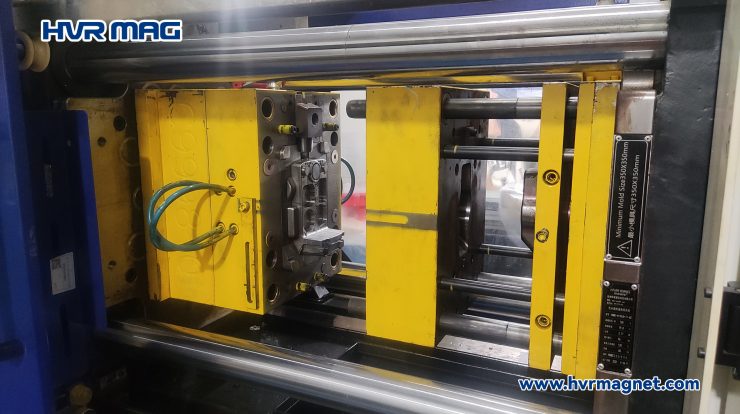

Magnetic Quick Mold Change System Change Mold in 7 Steps

In the injection molding process, mold changes can eat up valuable production time. That’s where magnetic quick mold change system comes in. Let’s delve into its seven-step process: Quick Mold…

How Magnetic Platens Position the Mold in a Quick Mold Change System?

Among the various components of a magnetic quick mold change system, the magnetic platens play a crucial role in precisely positioning the mold for optimal performance. Let’s delve deeper into…

Addressing High Mold Temperature in Magnetic Mold Clamping Systems

In the realm of injection molding, the efficiency and reliability of magnetic mold clamping systems are paramount. However, like any machinery, they can encounter challenges, particularly when mold temperatures soar…

Check If Magnetic Platen Is Compatible for Your Business

What is magnetic platen? Magnetic platen, also known as electro permanent magnetic mold clamping system, is often used in injection molding applications. It offers the advantages of quick mold changeover…

Understand the Applicability of Magnetic Platens

Injection molding is a widely used manufacturing process in various industries. One important aspect of injection molding is the clamping system, which is responsible for securely holding the mold in…

Magnetic Clamping Systems for Two-Color Molding Machine

A two-color injection molding machine is specifically designed to produce molded parts using two different colors or materials in a single injection molding cycle. This type of machine has the…

Magnetic Platen: Making Injection Molding More Eco-Friendly

Injection molding machines consume a considerable amount of energy during operation. Implementing energy-efficient equipment, optimizing production processes, and using energy-saving technologies can significantly reduce the energy consumption associated with injection…

How Do Magnetic Platens Work Under High Temperature?

Magnetic clamping system has emerged as a useful tool to enhance efficiency and accuracy in injection molding process. This system comprises two sets of electro permanent magnetic platens, with one…

Understand How Injection Molding Machine Uses Magnetic Clamping System

Magnetic clamping system is essential in the injection molding industry, offering numerous benefits despite certain operational challenges. If your company has not yet adopted a magnetic clamping system, it is…