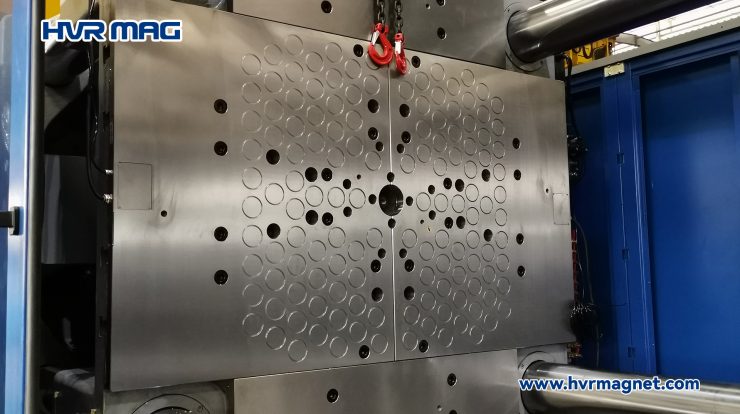

What is magnetic platen?

Magnetic platen, also known as electro permanent magnetic mold clamping system, is often used in injection molding applications. It offers the advantages of quick mold changeover in 3 minutes and uniform clamping press.

Which injection molding machine is magnetic platen suitable for?

There are three types of injection molding machines named by the driving system’s technology or method: Hydraulic Injection Molding Machines, Electric Injection Molding Machines and Hybrid Injection Molding Machines. Two types of injection molding machines are classified primarily by the mechanism construction: horizontal type of injection molding machines and vertical type of injection molding machines.

Usually, magnetic platens can be used for injection molding machines of all types, including tonnages ranging from 50 to 4000 tons.

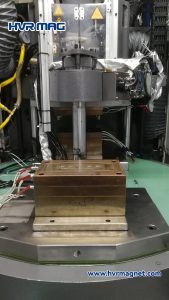

Is magnetic platen possible on a rubber compression press?

Despite being an intermittent operation, rubber injection molding boasts a short molding cycle, resulting in high production efficiency.

As long as the back of mold is flat and smooth and the mold temperature does not exceed 180 degrees Celsius, magnetic platen is also suitable for rubber compression press.

Industrial application

Automotive Industry: Magnetic platens are extensively used in automotive manufacturing for injection molding processes. They help in producing various automotive components, such as interior and exterior parts, engine components, and body panels.

Consumer Goods Industry: Magnetic platens are used in the production of consumer goods like household appliances, packaging materials, and plastic products. They allow for quick mold changeovers and efficient production cycles.

Medical Industry: In the medical field, magnetic platens offer precise mold clamping and positioning for producing accurate and high-quality medical products. Additionally, it preventing leaks of hydraulic oil, maintaining a clean and sterile environment is essential.

Conclusion

Magnetic platens offer a range of benefits that can positively impact the productivity, quality, and cost-effectiveness of manufacturing operations. By adopting magnetic platens, injection molding businesses can streamline their processes, increase output, and stay ahead in today’s competitive market. For more information, please contact HVR MAG at export@hvrmagnet.com