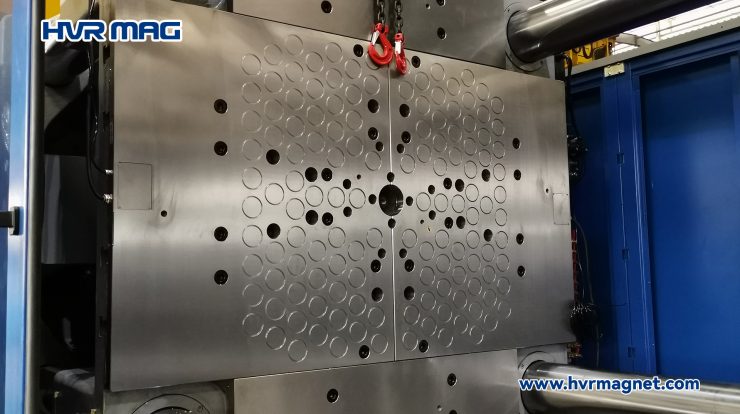

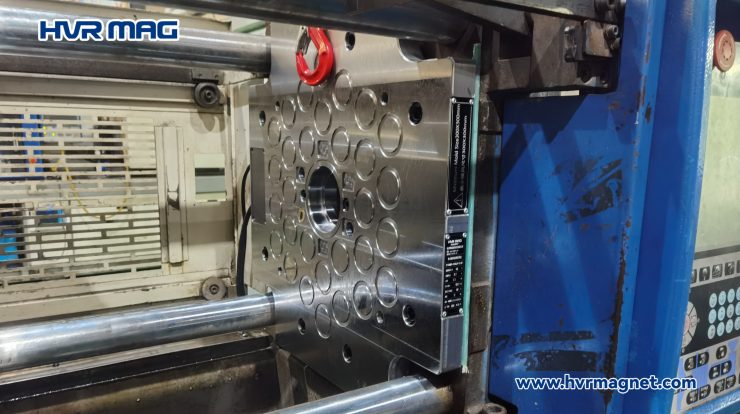

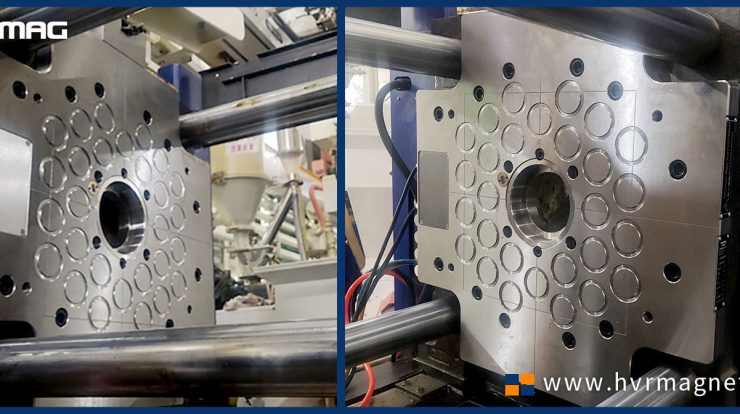

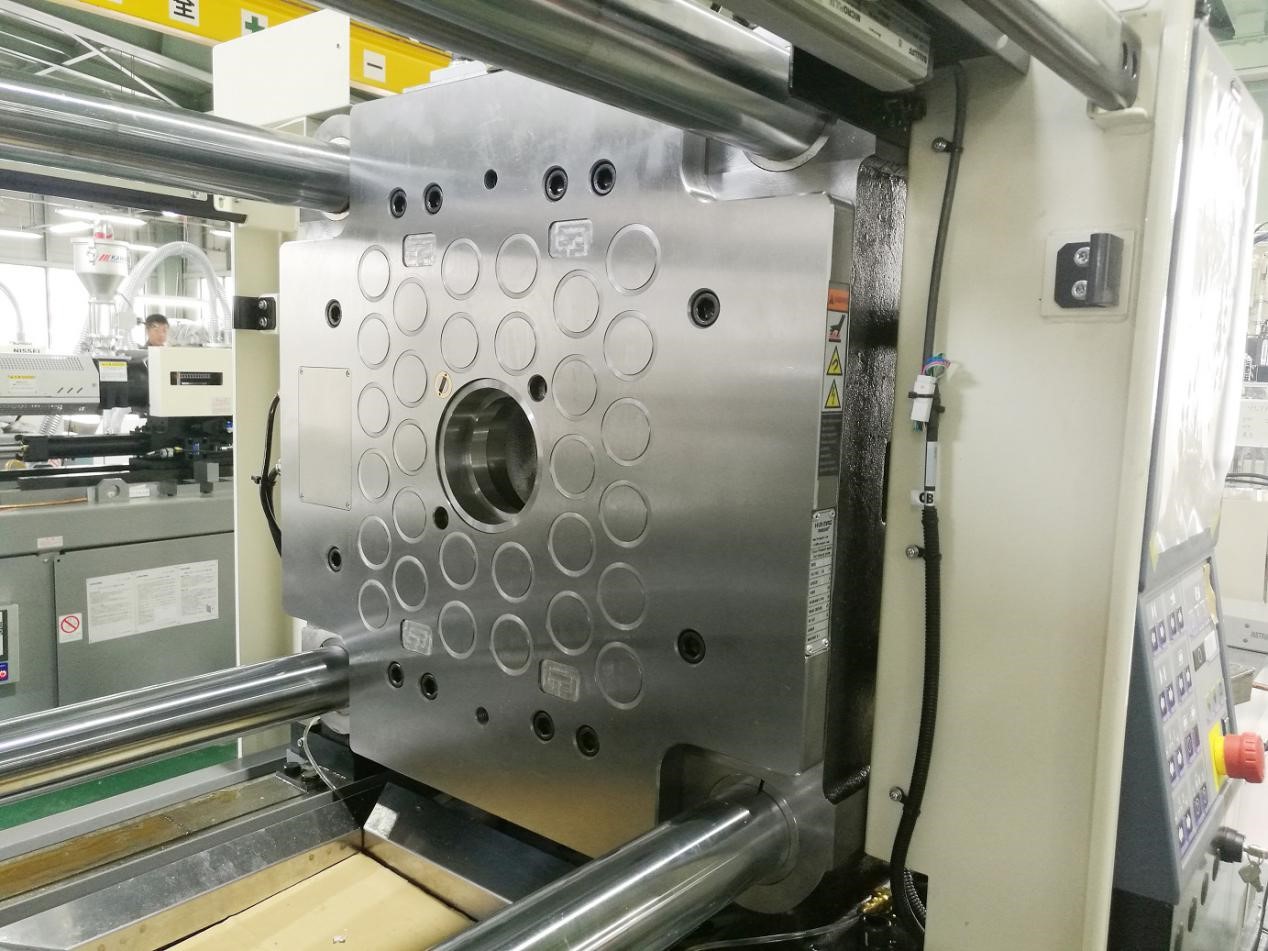

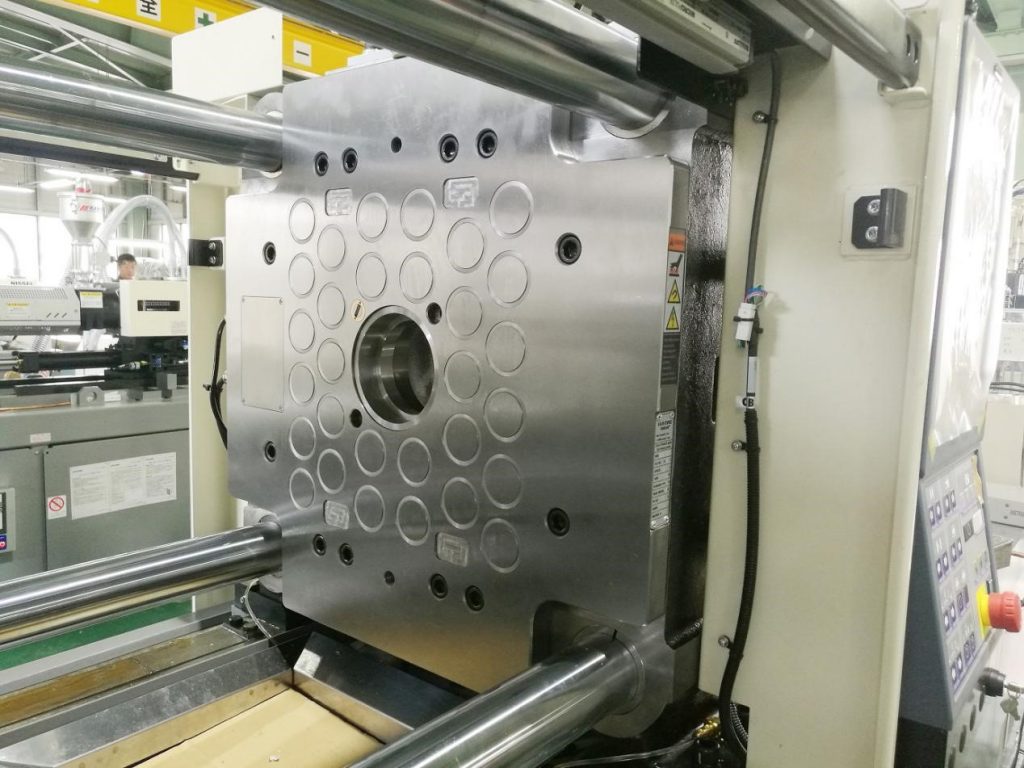

In recent years, the entire plastics industry has shown the following characteristics: the ageing of mold-changers, high labor intensity and high risks, and the reluctance of young people to engage in this industry. In addition, there are more and more customized products in small batches. In order to meet the needs of the market to improve efficiency and enhance the competitiveness of the industry, magnetic quick mold change system has become the primary project for customers to promote lean production.

Compared with the traditional mold change, magnetic quick mold change system can save more than 90% of the time when changing and installing molds. Moreover, the simple operation eliminates the need for the installer to master superb mold changing skills. In addition, magnetic quick mold change not only improves the accuracy of mechanical operation, but also greatly reduces labor costs and employee work intensity. However, compared with traditional mold change, magnetic quick mold change system is more costly. Therefore, some companies are hesitant to choose between the two mold change methods due to cost considerations. However, the introduction of the rapid mold change system will not only shorten the mold change time, but will also be of great benefit to the rationalization of factory management. This is the inevitable development trend of the injection molding industry in the future. For more information please visit www.magneticplaten.com