Magnetic Platens or Hydraulic Clamps – Quick Mold Change for 3300T IMM?

There are different types of quick mold change systems for plastic injection molding machines, among which hydraulic clamps and magnetic platens are the most commonly used. Do they perform the…

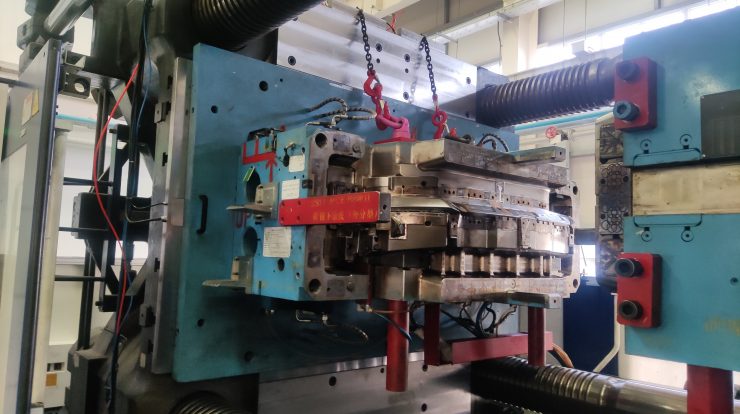

Injection Mold Clamp Plate for 1900T Rotary Table Twin-Color Machine

Check the latest live pictures about installation of injection mold clamp plate for 1900 ton FCS rotary table twin-color injection molding machine, in an automotive parts (like lamp housing) manufacturing…

Quick Change Mold Clamps for 370T/470T Haitian Injection Molding Machine

Many people in the plastic industry, have no idea about our quick change mold clamps, how they are used on plastic injection molding machines. Follow the feed-backs of installation site…

Online Support for Installation of Magnetic Platens on 350 Ton Haitian IMM

Due to the pandemic, our engineers are unable to go to client’s factory (in Vietnam) for guidance on installation of magnetic platens. But our online support finally nailed a successful…

Overview on the Application of Injection Molding In Automotive Industry

Injection molding is one of the most commonly used production processes for plastics, as it offers a viable solution for the mass production of high-quality injection automotive parts and components….

Magnetic Clamping for Different Types of Injection Molds

The type of injection mold affects component quality and manufacturing cost. While the selection of the type of it depends on the part geometry, tool design, production volumes, and budget. In…

Magnetic Mold Change – Everything You Need to Know

Learn what magnetic mold change is for injection molding machine, its procedures, features and advantages to plastic manufacturers.

Basics About Vertical Injection Molding Machine | HVR MAG – Magnetic Mold Clamp

What Is Vertical Injection Molding Machine?Vertical injection molding machines function the same as traditional horizontal machines, however they are orientated to operate on the vertical axis. The injection mechanism is…

Injection Molding Clamping Unit – Definition/Types/Comparison

What Is Injection Molding Clamping Unit? A clamping unit for an IMM is used to keep the mold shut against the forces developed when injection pressure pushes plastic into the…