Injection molding is one of the most commonly used production processes for plastics, as it offers a viable solution for the mass production of high-quality injection automotive parts and components. In the automotive industry, where consistency, safety, and quality are of utmost importance, automotive plastic injection molding is an important manufacturing process.

History of Injection Molding In Automotive Industry

In the early 2000s, automotive manufacturers unveiled the first plastic structural components for cars, which had the advantage of being more lightweight than their metal counterparts, unlocking improved fuel efficiency and cheaper production. Today, injection molding is now a dominant production method for manufacturing plastic car parts in the automotive industry.

Plastic injection molding continues to advance as new technology emerges, and with its growth comes new opportunities for using parts made with this method in automotive manufacturing. The global industry continues to work a higher percentage of plastic injection molding parts into each new round of vehicle designs, and plastic injection molding is capable of keeping up with demand. Find out why parts made with plastic injection molding are so popular across the European, North American, and Asian automotive manufacturing markets.

Advantages of Injection Molding In Automotive Industry

Injection molding is an established production process in which automotive mold manufacturers inject molten plastic materials into a mold cavity. The melted plastic then cools and hardens, and the manufacturers extract the finished part. Though the mold design process is critical and challenging (a poorly designed mold can result in defects), injection molding itself is a reliable method for producing solid plastic parts with a high-quality finish.

Here are a few reasons why the process is beneficial for automotive plastic parts production:

1. High Precision and Surface Finish

Injection molding is ideal for producing plastic parts with relatively simple geometries and results in high surface finish quality. Manufacturers have many finish options when producing parts, including various surface textures—such as glossy, rough, or matte—which they apply directly to the mold rather than the molded part. However, different plastic materials also influence the final surface finish.

2. Material Availability

A significant benefit of using injection molding for automotive production is the wide range of rigid, flexible, and rubber plastics the process is compatible with. Manufacturers use a wide range of different polymers for various applications in the automotive industry, including ABS, polypropylene, acrylic, acetal, nylon, polycarbonate, and more.

3. Repeatability

In the automotive industry, repeatability—or the ability to consistently produce identical parts—is crucial. Because automotive plastic injection molding typically relies on robust metal molds, the final molded automotive parts produced using the mold are practically identical. Some factors come into play with injection molding, but injection molding is a highly repeatable process if the mold has a good design and finishing.

4. Fast Prototypes with Rapid Tooling

Although automotive manufacturers widely use injection molding for mass production of auto parts, they also use it as a prototyping tool. By creating fast, low-cost aluminum molds with rapid tooling — usually by additive manufacturing or CNC machining — automotive mold manufacturers can turn around short runs of prototype molded car components much faster than traditional (steel) tooling.

5. Scale and Cost

The injection mold-making process can be an expensive process due to the cost of the mold. However, it remains a highly scalable process whose overall cost decreases as the manufacturer makes more parts. For mass production applications, injection molding is thus beneficial to the manufacturer. For anything less than mass production, however, injection molding tooling costs may curb the cost efficiency of the process.

6. Color Options

In automotive plastic injection molding, it is easy to modify the colors of molded automotive parts to fit the vehicle’s color scheme. Unlike other processes, injection molding allows you to mix dyes with the raw material pellets before manufacturing begins. This produces solid, consistent coloration without the need for painting or tinting after the molding is complete.

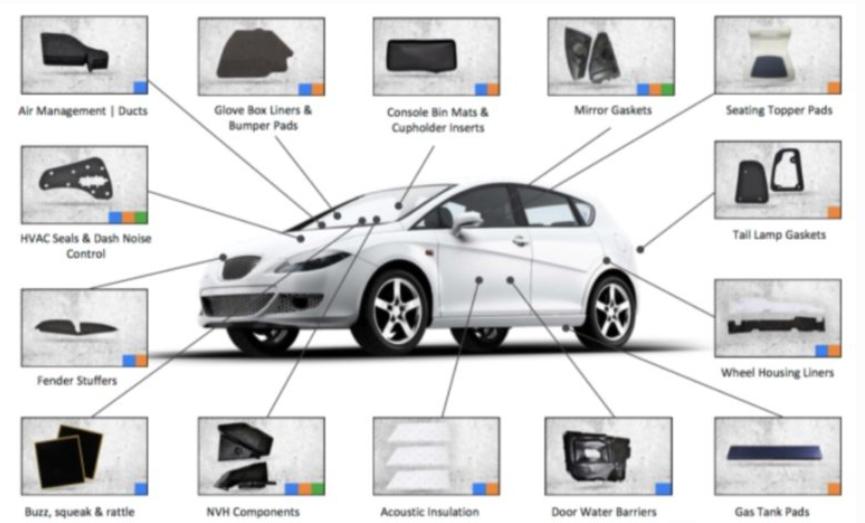

Plastic Injection Molding for a Variety of Interior & Exterior Components and Engine Parts In Automotive Industry

In the automotive sector, injection molding is one of the predominant methods manufacturers use to form plastic parts. However, it would be difficult to make a list of plastic components in a car produced using injection molding, so we’ll look at some of the main sectors.

- Components under-the-hood

2. Exterior Components

Injection molding is an established process for many exterior automotive components, including fenders, grilles, bumpers, door panels, floor rails, light housings, and more. Splash guards are a fine example for demonstrating the durability of injection molded parts. In addition, the components, which protect the car from road debris and minimize splashing, are often made from rubber or other durable and flexible materials.

3. Interior Components

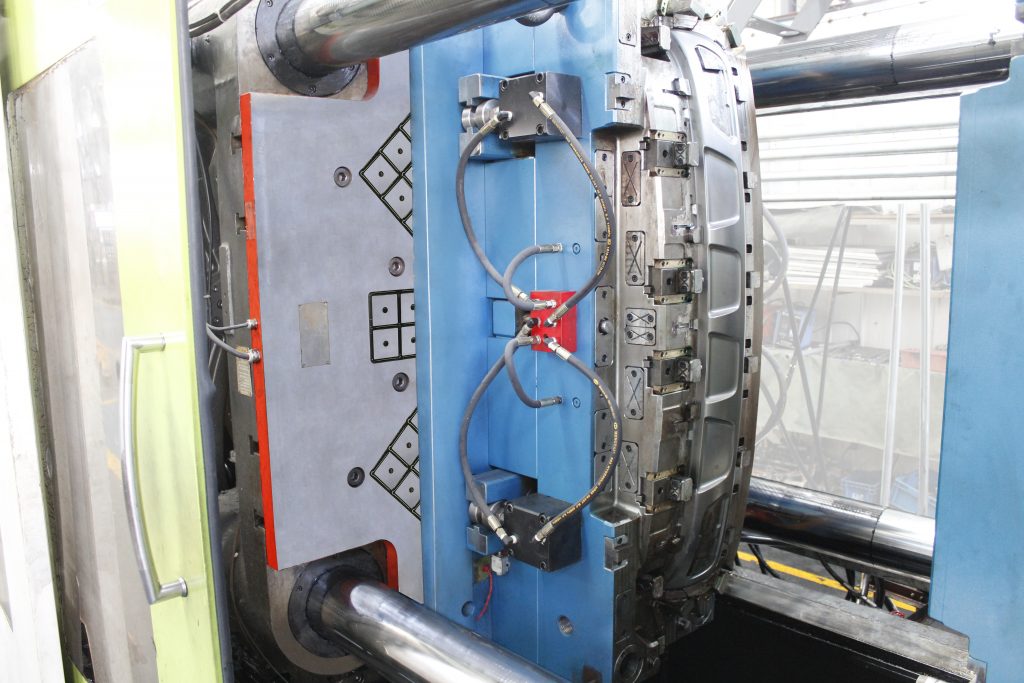

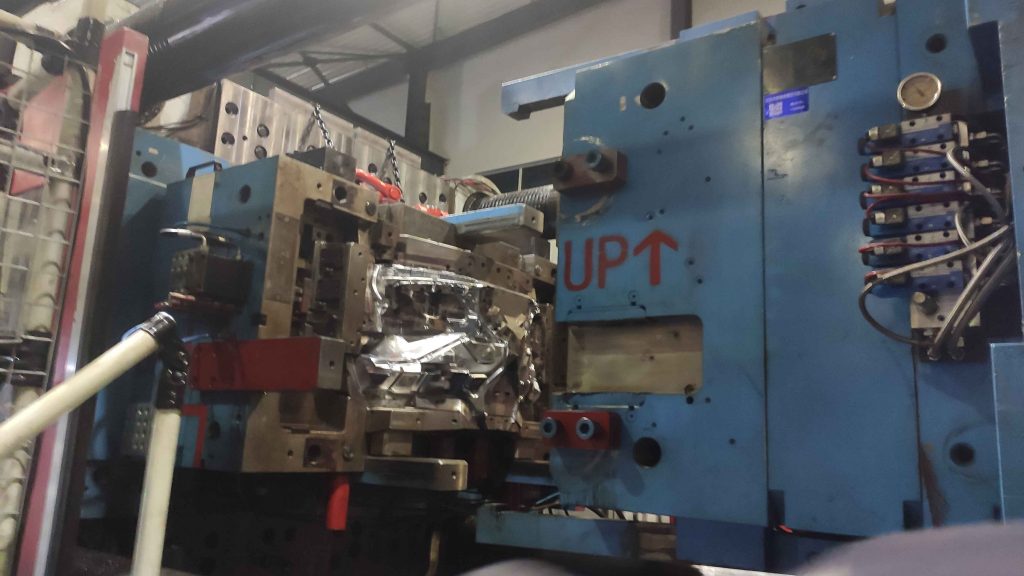

Examples of Injection Mold Clamps Used In Manufacturing Automotive Parts

Molds for making automotive parts and components are often large and super heavy, which sets higher and more demanding requirement on the mold clamps. Magnetic platens, are mold clamping devices used on injection molding machine to achieve quicker mold change during daily molding processes. Strong and uniform magnetic clamping force, uninterrupted by a sudden power outage or failure, magnetic mold clamps are a safer and more efficient type of mold clamp that has great flexibility on molds, which means they have no restrictions or limitations on the size of mold.

Discover more about the working principle of magnetic mold clamps, and their applications for injection molding in automotive industry, welcome to visit our website www.magneitcplaten.com to find out more. Or contact us for queries and doubts.