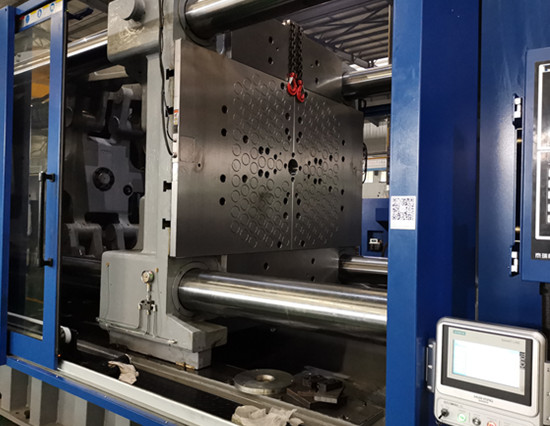

What Is Injection Molding Clamping Unit?

A clamping unit for an IMM is used to keep the mold shut against the forces developed when injection pressure pushes plastic into the closed mold. It includes a drive mechanism for moving a moving platen of the injection molding machine in at least one direction.

What Are the Three Basic Types of Injection Molding Clamping Units?

Some think there are only 2 types of clamping units for injection molding, while actually there are 3.

Injection Molding Toggle Type Clamping Unit:

A toggle clamping unit for an IMM includes a toggle link, a crosshead connected to the toggle link, and a driving device for driving the crosshead. It is mainly used for high speed injection molding.

Advantages:

Low cost and lower horsepower needed to done

Positive plan of the mould

Disadvantage:

Unable to read the clamp force

Clamping is more difficult

Higher maintenance has lubricant is provided

Injection Molding Hydraulic Type Clamping Unit

A clamping unit actuated by hydraulic cylinder, which is directly connected to the moving, closed the mould. There are two halves in hydraulic cylinder, which is actually inlet and outlet of oil.

Advantages:

Clamps speed easily controlled and support at any point

Direct read of clamping force

Easy adjustment of clamp force and easy mode set up

Low maintenance

Disadvantage:

It is a higher cost and more expensive then toggle system

Noun positive clamp

Magnetic Type Clamping Unit (the type that’s been neglected the most)

Clamping force generated by the magnetic modules inside the magnetic mold clamping plates or platens. Magnetization and demagnetization of the platens, mold clamping and mold changing can all be operated through the interface panel.

Advantages:

No energy consumption during the clamping process; only needs electricity in magnetization and demagnetization phase

Real-time reading of clamp force with 8 safety attributes.

Maintenance free

If you want to learn more about the last type of injection molding clamping unit, welcome to visit magnetic platens manufacturer’s website.