Check the latest live pictures about installation of injection mold clamp plate for 1900 ton FCS rotary table twin-color injection molding machine, in an automotive parts (like lamp housing) manufacturing workshop.

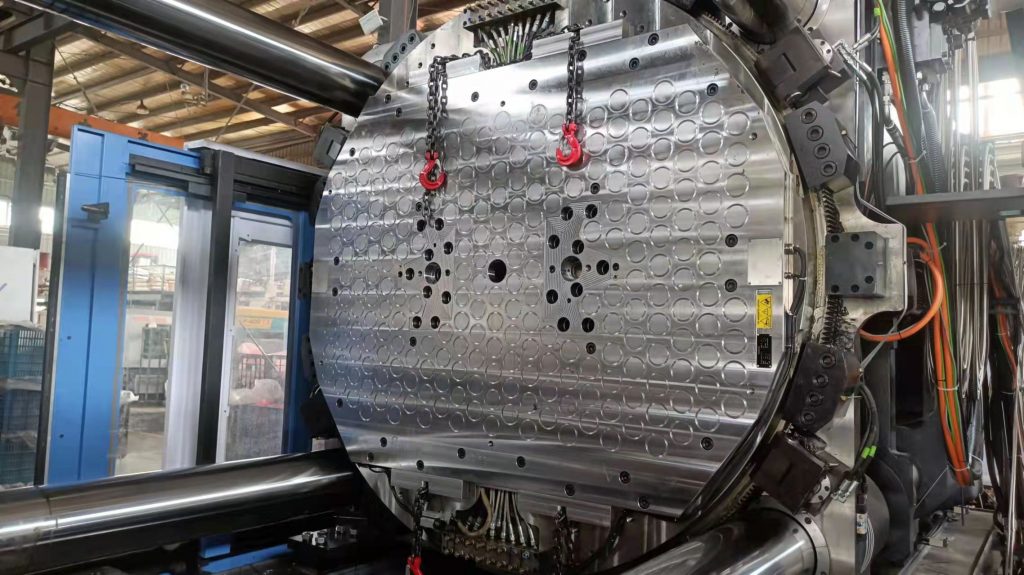

Loading the magnetic injection mold clamping plate for installation

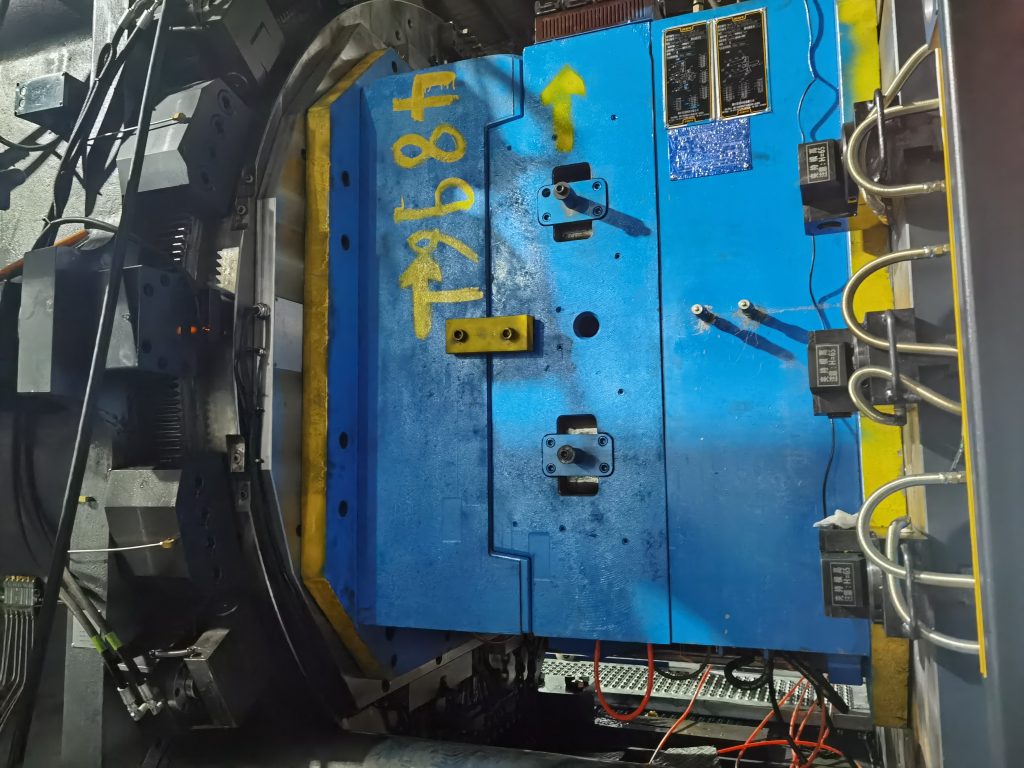

After installation on the rotary table of machine

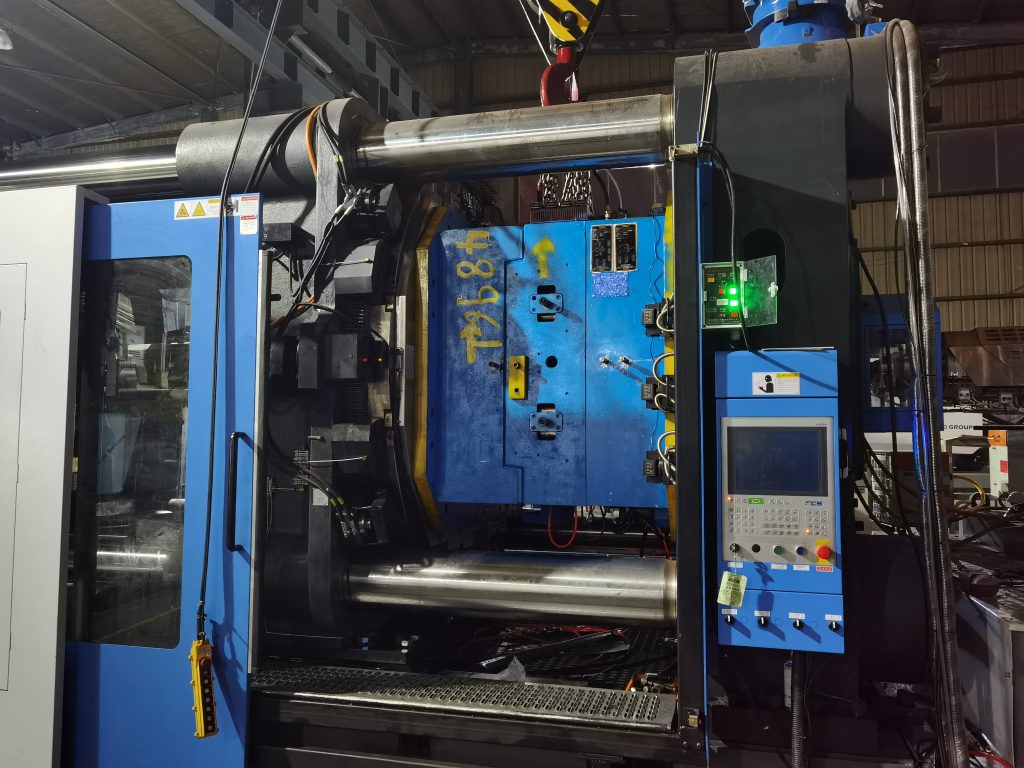

Full view of injection molding machine and the mold clamping plate

Operation panel for magnetic clamping system

Loading the new mold

Magnetic mold clamp plate installed on the rotary side of machine; hydraulic clamps on the fixed side.

Mould opening test for injection mold clamp

Our magnetic platen is useful for clamping of moulds on plastic injections moulding machines. During the mold changing process, instead of manually loosening and tightening every bolt, the machine operator simply just need to press the buttons on the interface panel to release and secure the clamp holding of the mold.

How to setup molds on rotary table injection molding?

If you’re using customized magnetic injection mold clamp plates, just magnetize the plate to clamp the mould, and demagnetize it to release the mould. It’s that simple.

In addition, our magnetic clamping system, has no limitation or restriction on the size of molds. Also, using magnet plate is much space-saving than using hydraulic mold clamps, which is why this factory chose HVR MAG to help changing moulds.