What Is Vertical Injection Molding Machine?

Vertical injection molding machines function the same as traditional horizontal machines, however they are orientated to operate on the vertical axis. The injection mechanism is typically located at the top of the mold.

Vertical injection molding machines require very little floor space due to the orientation of the machine. They are particularly suited for insert molding applications. Components can be easily loaded into the mold and held in place by gravity prior to over molding.

Often they incorporate a shuttle or rotary table, allowing loading and demolding within the machines cycle time. This allows for work with multiple molds and simultaneous operations — pre-molding, injection molding and post-molding. As a result, there is less of a need for manual operation and intervention, as well as higher efficiency, increased productivity and reduced costs.

What Is the Difference between Vertical and Horizontal Injection Molding Machine?

The primary difference in vertical vs. horizontal injection molding is the configuration and movement of the mold.

In the vertical injection molding process, the mold clamping action occurs vertically, in an up and down motion. The injection device and the clamping device are on the same vertical center line, and the die is opened and closed along the upper and lower directions. The clamping mechanism and injecting mechanism are located along the same vertical plane. While in the horizontal injection molding process, the mold clamping action occurs horizontally, with each half of the mold moving sideways to join.

Another key difference in a vertical mold, as compared to a horizontal mold, is that pieces do not automatically fall out of the mold after being ejected (as is the case with horizontal molds). In vertical molds, pieces must be extracted by hand or robotic arm.

Vertical Injection Molding Machine Advantages:

✦Space Saving – vertical injection molding machinery takes up half the space compared to horizontal machines used for the same functions.

✦Allows for insert or plastic-metal combined component molding.

✦Gravity dislocation is eliminated due to the vertical injection machine mold alignment. Molds are aligned and supported in the vertical machine with more durability.

✦Vertical clamp units are versatile and accommodate attachments.

✦Automatic operation is ideal for the vertical clamp injection molding machinery without the use of an attendant.

✦A wide selection of the vertical clamp unit options also makes it appealing.

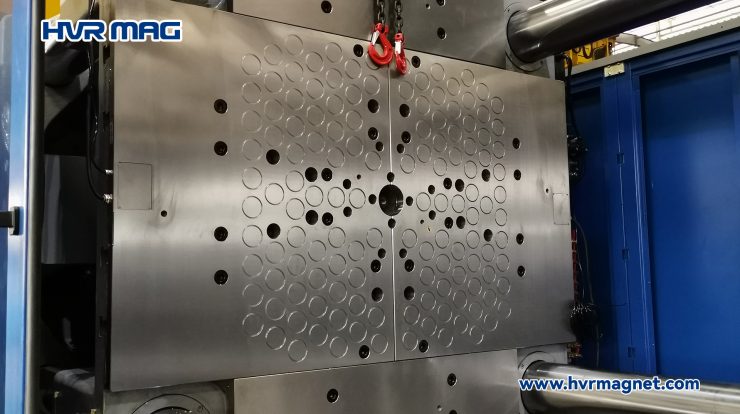

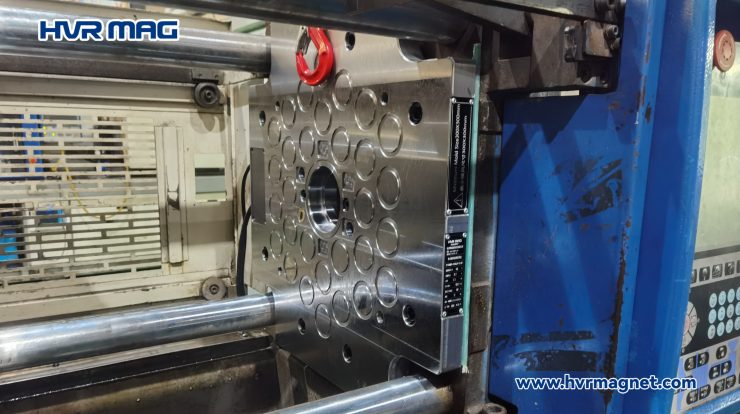

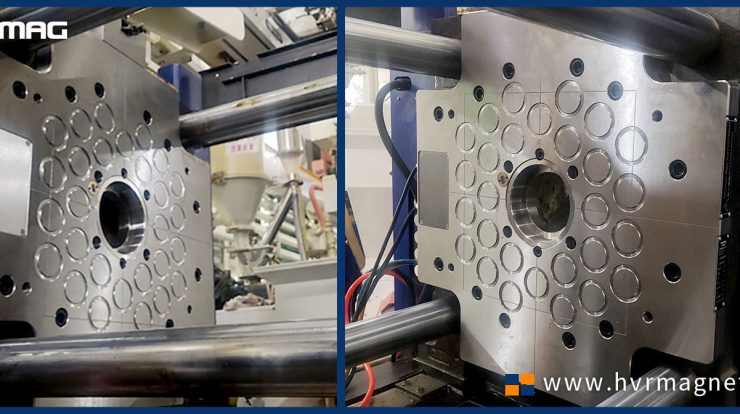

No matter the vertical injection molding machine, or the common horizontal type, the mold can be clamped and quickly changed with magnetic mold clamping plates. This quick mold change system can reduce your machine downtime within several minutes. Learn more about magnet mold clamp, go to our website:www.magneticplaten.com