How Magnetic Quick Mold Change System has become a Mainstream Product for Injection Molding Machines?

How magnetic quick mold change system has become a mainstream product for injection molding machines? Quick mold change is the development direction of the worldwide injection molding industry. In recent years, the Chinese market has changed significantly and the technology has been upgraded rapidly. So it is impossible to win in the current market situation simply by relying on cheap labor and low-cost resources. At present, what customers pay most attention to is not the price factor, but the production efficiency and product performance. Enterprises need to upgrade their technology to achieve greater added value.

How to calculate the benefit of quick mold change for plastic injection molding?

How to calculate the benefit of quick mold change for plastic injection molding has become a vague concept. So today’s essay we are going to talk about which way of calculation is more reasonable for us.

Collaboration with Our Magnetic Mold Clamping Symtem Distributor

Today I’ ll give a personal description about the collaboration between Sandsun & HVR, which may give us some hint about the plastic injection molding industry.

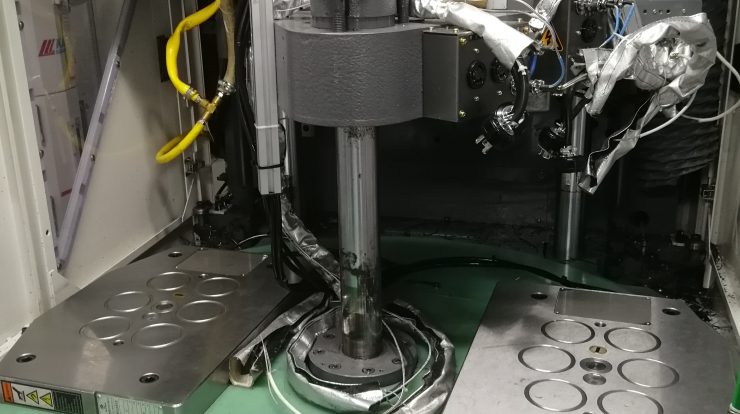

Magnetic Mold Clamping Solution for Vertical Injection Molding Machine

Today I’d like to share with you this application case of small tonnage magnetic mold clamping solution for vertical injection molding machine.

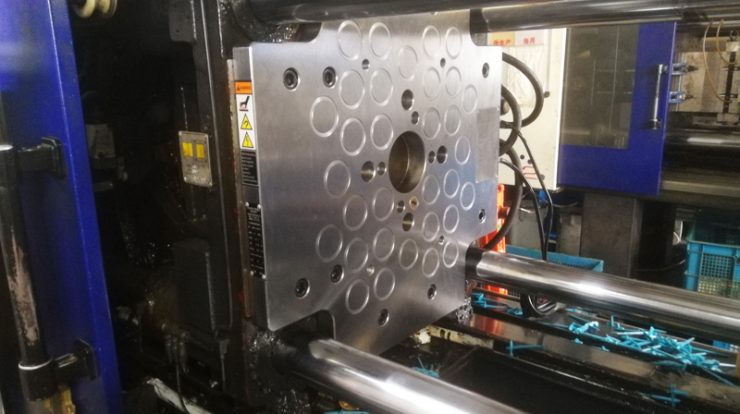

Plastic Factory Introduced Magnetic Quick Mold Change System

A plastic injection molding factory in Zhongshan City, Guangdong Province introduced 3 sets of magnetic quick mold change systems from HVR MAG. The clamping tonnage of the injection molding machines matched with the 3 sets of magnetic platens is 650 T, 850 T, and 1000 T respectively.

Magnetic Mold Clamping for Medical Injection Mold

Magnetic quick mold change system improves the medical plastic injection molding, according to HVR MAG’s customer from Jiangsu Province.

Clamping Magnet of Quick Mold Change for PMMA Molding

Why magnetic mold clamping quick mold change solution for PMMA injection molding is successful?

Comparison Between Hydraulic and Magnetic Mold Clamping Systems

This article introduces the difference between magnetic and hydraulic quick mold change to provide a reference for efficiency improvement in the injection molding industry.

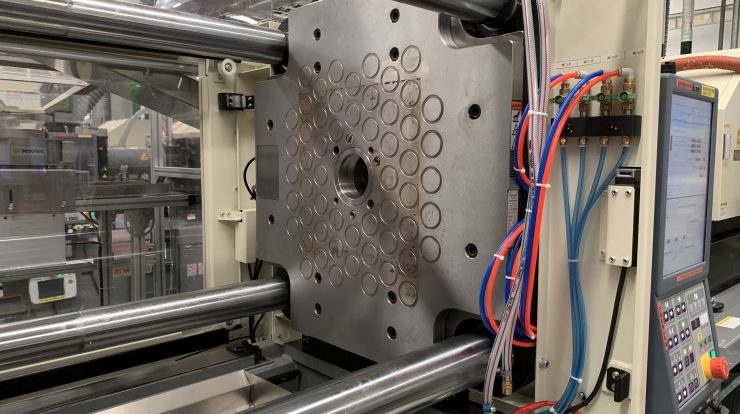

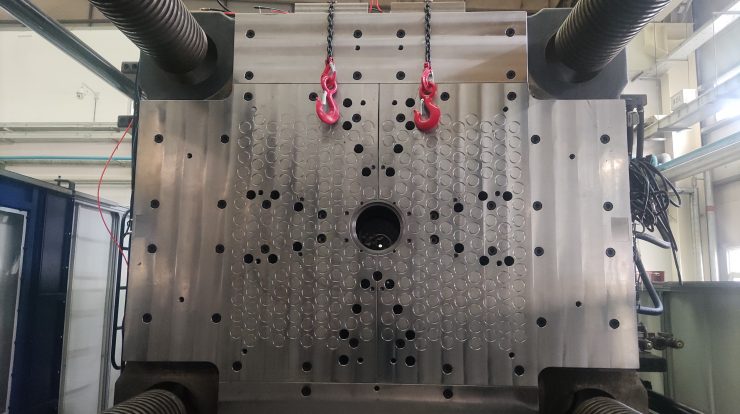

Injection Mold Clamp – Magnetic Platens for Large Tonnage Injection Molding Machines

As an important part of any moulding operation, injection mold clamp is widely used in any injection molding machines or metal stamping presses for holding the mould/die part between the…