The type of injection mold affects component quality and manufacturing cost. While the selection of the type of it depends on the part geometry, tool design, production volumes, and budget. In this article, we’ll talk about various types of injection molds, their construction and the magnetic clamping system for them.

To start with, let’s familiarize ourselves with Different Types of Injection Molds.

The following types of injection molds are used to manufacture plastic parts using the injection molding process.

1. Feeding System

- Hot Runner Injection Mold

- Cold Runner Injection Mold

2. Number of Cavities

- Single Cavity

- Multi Cavity

- Family Mold

3. Mold Opening

- Two Plate Mold

- Three Plate Mold

Based on Feeding System

Injection molds can be classified into two types according to how molten plastic comes inside injection molds: hot runner injection molds and cold runner injection molds.

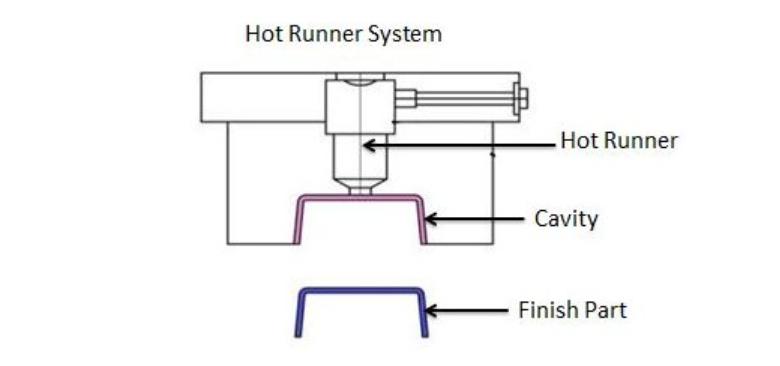

Hot Runner injection Mold (consists of a heated physical channel to direct molten plastic to an injection mold tool cavity, like the following chart shows)

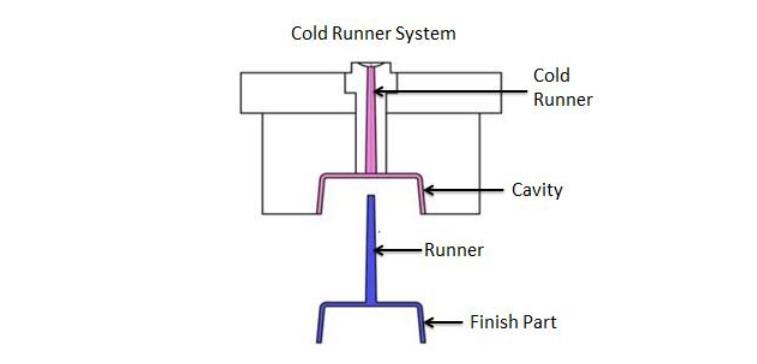

Cold Runner injection Mold(consist of an unheated physical channel to direct molten plastic into the injection mold tool cavity after it leaves the nozzle, shown as below)

Based on Number of Cavities

Injection molds can also be classified into three types according to the number of parts produced per injection cycle: single cavity, multi-cavity, and family mold.

Single Cavity Injection Mould

Single cavity mold produces only one part per cycle. The injection molding tool cost for a single cavity mold is small, whereas the unit part cost will be higher. It has applications for low production volumes, and possesses flexibility in controlling the injection molding process.

Multi Cavity Injection Mould

Multi cavity injection mold produces more than one part per cycle. The initial investment cost is higher but the unit part cost is low for multi-cavity injection tools.

●Multi cavity molds are used to increase the production rate.

●The cost of a multi-cavity injection mold is higher as compared to a single cavity mold.

●A higher tonnage machine is required to run a multi-cavity mold as compared to a single cavity mould.

Family Injection Mold

Family injection mold produces two or more different parts per injection cycle. In this per part injection mold price reduces because we manufacture different plastic parts in a single mold.

For example, you can manufacture top and bottom cover for plastic housing in one injection cycle. But both parts shall be in similar color and material.

Based on Mould Opening

According to how core separates with cavity injection molds can be classified into two types. Read this article for more detail on two plates and three plate mold here.

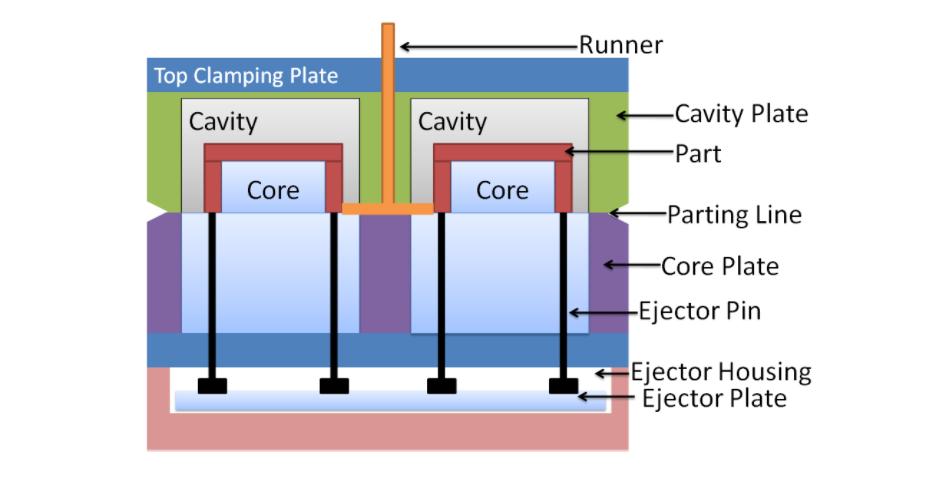

Two Plate Injection Mold

Two-plate molds are the most commonly used type of injection molds. They consist of one parting plane where the mold splits. In a multi-cavity two-plate mold, runner and gate must be in the parting plane to ensure runner and gate ejection when mold split.

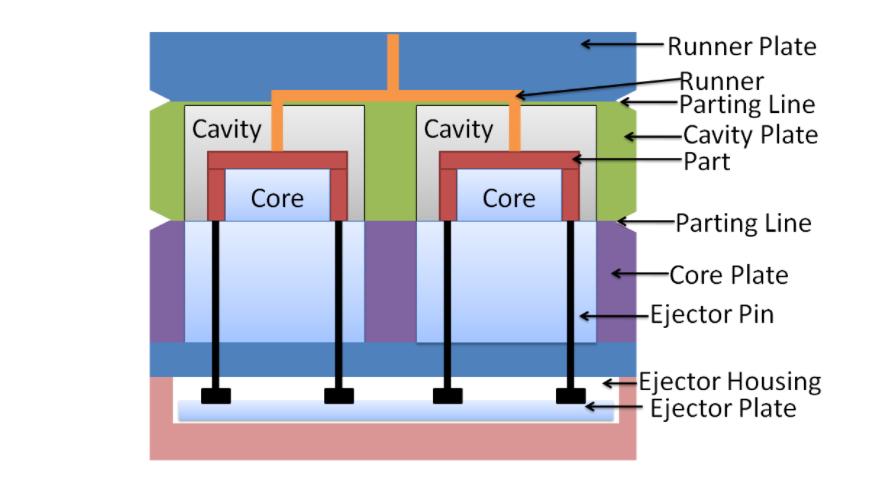

Three Plate Injection Mold

Three plate injection mold consists of two parting planes and mold splits into three sections. Therefore runners and components can be located on different parting planes. In three plate molds, the runner is ejected separately to the molded part. Therefore automatic de-gating is possible.

To sum up, the types of injection molds selection depends on the part geometry, tool design, required quality, and production volumes.

Magnetic Clamping for Different Types of Injection Molds

Single cavity injection mold clamping on 200 ton LANSON IMM

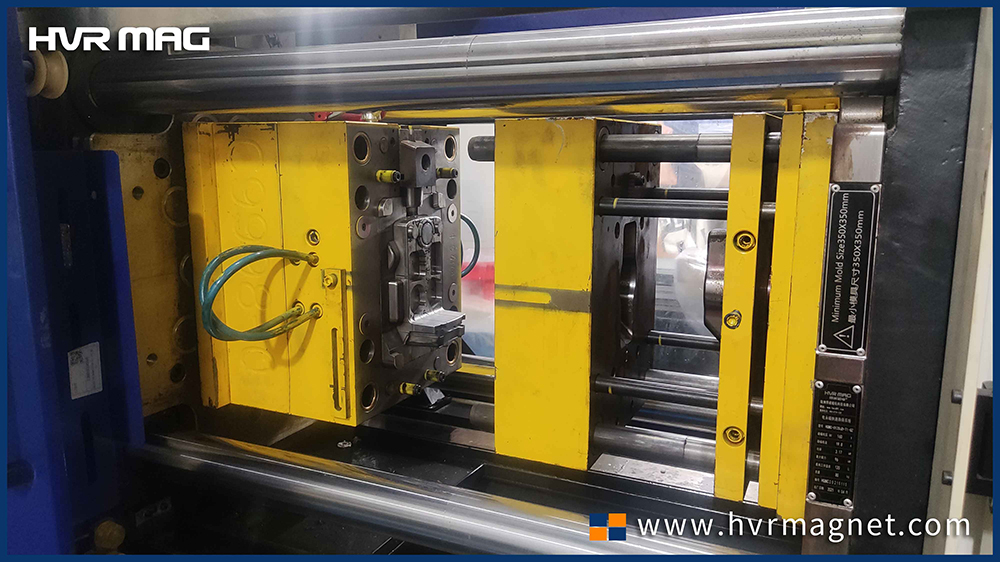

180 ton magnetic platens for multi-cavity injection mold on IMM

Magnetic clamping for two-plate injection mold

Magnetic clamping for three-plate injection mold, in a toy manufacturing factory

As a professional provider of magnetic clamping system for molds & dies, HVR MAG can supply quick mold change solution for 50-4000 ton injection molding machines. Learn more about our magnetic clamping technology, please visit our website www.magneticplaten.com to find out more.