Introduction:

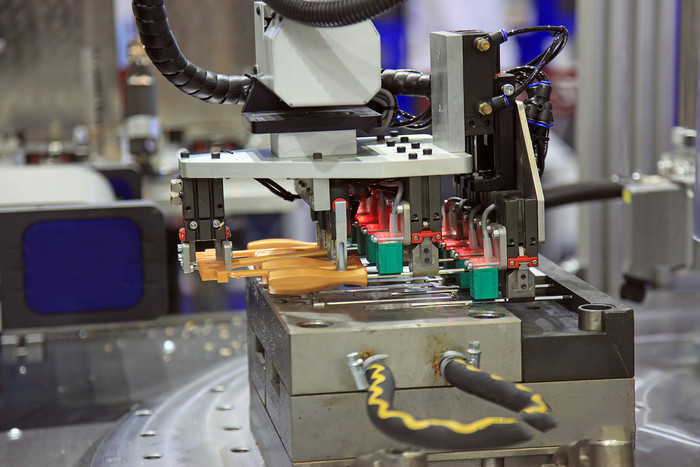

Many plastic injection molding and metal die casting manufacturers, are now facing the problem of higher labor costs and long downtime because of frequent mold (die ) changeover. Hence, to solve the problem, most of them are now considering the introduction of a more efficient, energy-saving and safer mould (die) change system: the Quick Mold (Die) Change System. Yet the manufacturers also have some questions before their buying of such new system. Therefore we HVR MAG collected some frequently asked questions(FAQ) about quick mold change and answered them here. This part is an addition to our previous Q&A (Click to read FAQ Part I ). Hope you’ll find it useful.

Questions & Answers:

FAQ 1.Is the magnetic quick mold change system suitable for most injection molding machine types?

Yes, our magnetic quick mold change system is suitable for 50~4000 TONS injection molding machines.

FAQ 2.What are the advantages of electro-permanent magnetic quick mold changing system compared with hydraulic quick mold changing system?

There is no need to change the injection molding machine template, no need to unify the mold back size, no need to worry about oil leakage, noise and other impacts on the environment.

FAQ 3.What machine parameters need to be provided to you for the quick mold change system?

Here are what we need in order to custom design your magnetic platens for your injection machine: Injection molding machine brand, type, clamping force, external dimensions of the static and dynamic formwork installation, fixed hole size, positioning ring diameter and height, push rod diameter and length, working temperature, and mold related parameters. As for special molds, especially slender ones, please list the detailed parameters.

FAQ 4.Whether there is a danger of falling off of the mold installed on the magnetic platens of the injection molding machine?

The mold is clamped on the electro permanent magnetic platen by the electronically controlled permanent magnetic force. As long as the temperature is not higher than the set temperature, the push rod stroke is accurate and the push rod hole position is correct, the mold will not be stuck. And if the mold opening force is set below 45% of the mold closing force, and the back of the mold is kept flat and clean, there will be no danger of falling off. Besides, there are safety chains that hold the mold in place so there is no danger even when the mold falls off.

FAQ 5. How to control X tonnage mold from falling down?

We will set the number of magnetic poles according to the weight and size of the mold, and the magnetic force of each 70 magnetic poles can reach 680KG conservatively. In practical use, taking friction into account, the molds can still be firmly attached without any displacement.

In addition, the control system is equipped with 8 safety precaution system, which alerts and stops the automatic operation of the injection molding machine in the event of a decrease in magnetic flux, or a slight movement of the mold. It can therefore be used with confidence.

HVR MAG has been a reliable supplier of custom designed quick mold (die) change system. Its HQMC System has gained a good reputation in the market both domestic and abroad. You are very welcomed if any questions for us about electro-permanent magnets for lifting, quick mold (die) change, cnc chucks, and automation robotics. We will continue to post articles of FAQs about quick mold change (QMC).