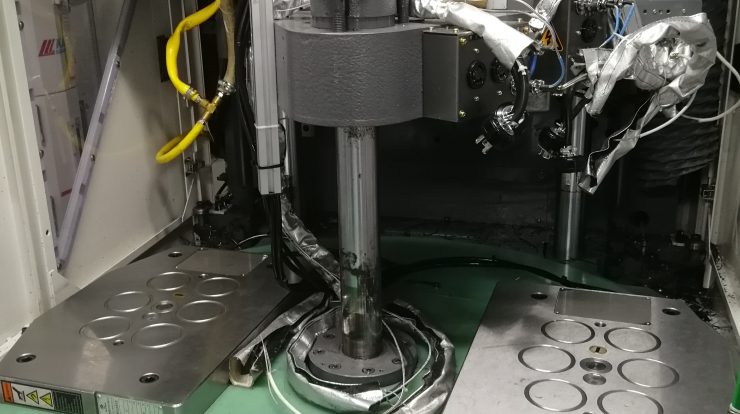

Today I’d like to share with you this application case of small tonnage magnetic mold clamping solution for a vertical injection molding machine.

About vertical injection molding:

We know that from a function perspective, vertical injection molding machines play the same role as horizontal injection molding machines. The difference lies in how they work. Vertical injection molding machines are oriented to run on a vertical axis. And they are available in hydraulic, electric and hybrid actuation modes to meet a range of customer needs. They only need a small footprint due to their orientation and are therefore particularly well suited for insert molding applications. The term insert molding may sound a bit specialized, but many common items in life are manufactured from insert molding, like electronic and electrical parts, computer parts, power plugs, medical supplies, stationery items, sporting goods (golf balls), eyeglasses, metal powder injection parts, etc.

Why HVR magnetic mold clamping solution?

The small tonnage vertical injection molding machine that our customer used was with a rotary platen and a custom platform. It was to produce electronic parts. The customer used to manually change the mold, which cost too much time. They knew us from the Internet and came to query. But the customer later told us that before he placed the order, he also went to compare and understand the hydraulic mold change method. But then he knew that the magnetic mold clamping method was cleaner and faster, and needed much less maintenance. They still decided to place the order with us under the circumstance that the magnetic quick mold change system was more expensive.

After adopting HVR electro permanent Magnetic Platens for quick mold change. The loading and unloading of the mold now take just a few minutes, especially suitable for the customer’s multi-species and small batch run. It also helps them to reach JIT (just-in-time) production mode. Now their customer has been more satisfied with their product quality since their working environment becomes cleaner. The boss and employees breathe a long sigh of relief to have such magnetic mold clamps helping them change mold with ease and efficiency.

Are you looking for quick mold change systems? Try HVR HQMC magnetic mold clamping solution for both vertical and horizontal injection molding machines. For over 15 years, HVR has been focusing on nothing but electro-permanent magnets. We want to be trusted by our clients because of a high degree of professionalism and dedication.