Why is Magnetic Clamping for PMMA Injection Molding Machine successful?

When talking about injection molding, what usually comes to our mind is plastic injection molding. The plastic contains a poly acrylic acid-based plastic. PMMA, full name Poly methyl methacrylate, is one of them. The clamping magnet for quick mold change system that we are going to talk about today, can be applied to the PMMA injection molding process.

Why Magnetic Mold Clamp can do for PMMA Injection Molding?

PMMA ,commonly known as Plexiglas, is an engineering plastic. During injection process, the flow of PMMA is worse than PS and ABS, and the melt viscosity is more sensitive to the change of temperature. In the injection molding process, the melt viscosity is changed mainly from the injection temperature.

Because of these disadvantages, its mold temperature is generally set at 60℃-80℃ during injection molding; and this temperature is also the working range that the magnetic mold clamping system is fully capable of, and will not have much negative impact on its magnetic clamping force.

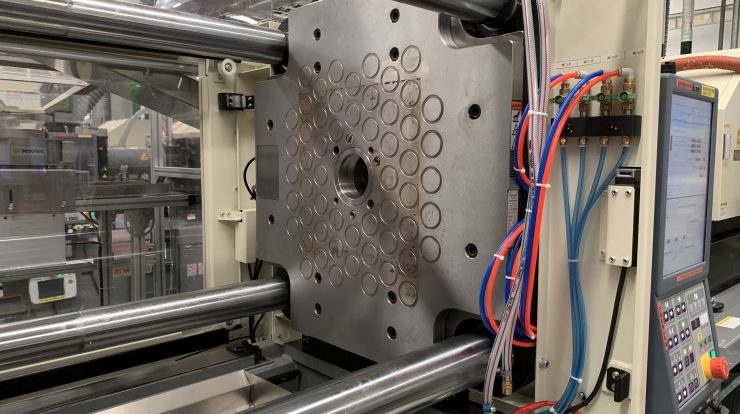

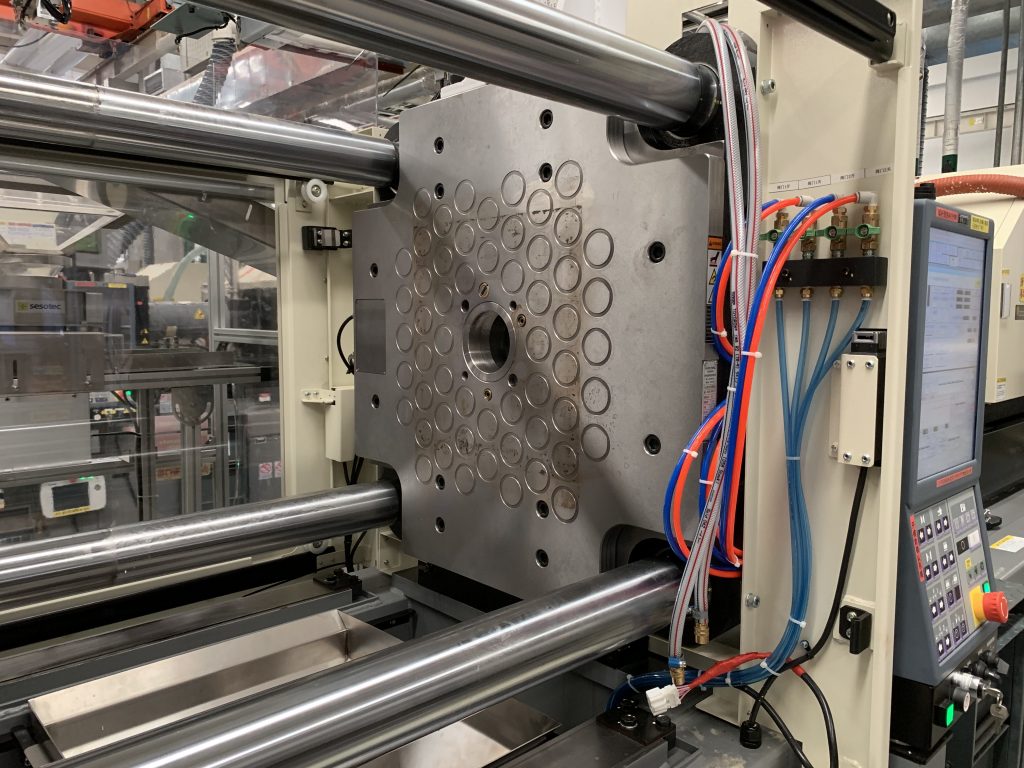

In addition, PMMA injection molding is generally recommended to use fast injection due to poor fluidity. But to avoid high internal stress, it is advisable to use multi-stage injection, such as slow-fast-slow, etc. When injecting thick parts, high pressure and slow speed is used. This variation of injection speed, as well as the internal stresses generated after the mold is closed, all put high demands on the mold clamping force. Our magnetic quick mold change system can provide uniform and stable mold clamping force for 50~4000 tons injection molding machines, which greatly eliminates the risk of mold loosening or deformation due to temperature and injection speed variation, thus improving product quality.

And compared with the traditional and hydraulic mold clamping methods, magnetic clamping system has irreplaceable high efficiency. For more comparison information between hydraulic clamping and magnetic clamping systems, please click,or watch a video to know more: https://www.youtube.com/watch?v=oR0049BXflE

HVR MAG has been concentrating on electro permanent magnet since its foundation, and has achieved an industry-leading position in China. Our products serve the fields of steel lifting, CNC magnetic clamping, magnetic mold clamping system of quick mold change for injection molding machines, die presses, and metal stamping machines, and magnetic grippers for automation. And we have had many successful cases of magnetic mold clamping quick mold(die ) change solution for PMMA injection molding or other related machines.

If you are interested in efficiency improvement of your mold clamping for your PMMA injection molding or other plastic injection molding, die pressing, and metal stamping, you are always welcom to get a free query at: export@hvrmagnet.com