Mold change has long been a headache for injection molding manufacturers. Because of mold variety, size, and often heavy load, each traditional mold changeover often takes hours to complete. Moreover, with the increasing number of small batch size customized products, frequent mold changes have become the norm. Hence, the production efficiency of enterprises will undoubtedly impact the inability to meet customer needs in a timely manner. Under such conditions, enterprises have to seek solutions to solve the problem of inefficient mold change.

That’s why the quick mold change system for injection molding machines is fast becoming the choice of many manufacturers to meet the development of the times. At present, in addition to the traditional manual mold(die) change method, there are mainly hydraulic mold(die) clamping and magnetic template on the market, today we will talk about the advantages and disadvantages of these two mold(die) change methods respectively.

1. What mold change time is:

The mold change time is the time consumption required from after the completion of production of the last piece of the previous product and then the mold switch until the first qualified product of the new mold is produced.

2. A Brief comparison of hydraulic and magnetic clamping

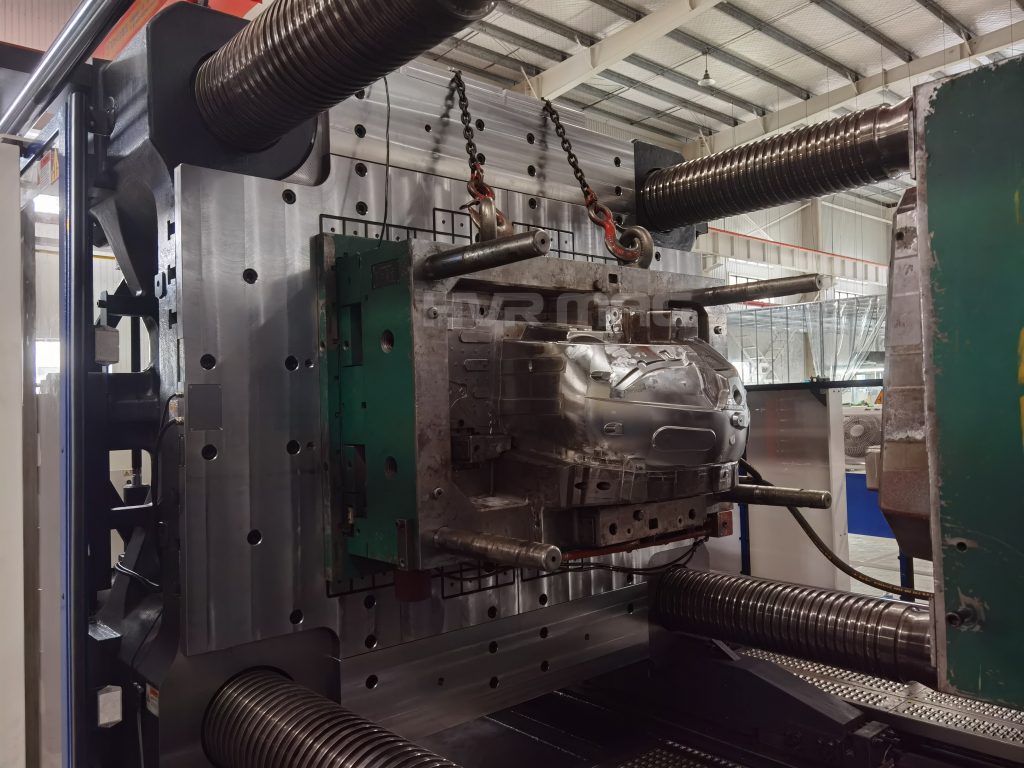

Hydraulic clamping for quick mold change is a common way to change the mold under the premise that the magnetic mold change is not yet popular.

Advantage:

This way of mold change is less time-consuming than manual mold change.

It is less expensive, and the initial investment is small, suitable for small enterprises or manufacturers.

Disadvantage:

Limit on the thickness of the base plate of the mold.

nonuniform clamping force: hydraulic clamping pressure, generally clamping 4 points around the template back plate more tightly while clamping the central part not so tightly. Easy to cause mold deformation during the working process.

Low reliability and safety performance: there is no automatic safety signal once a problem occurs.

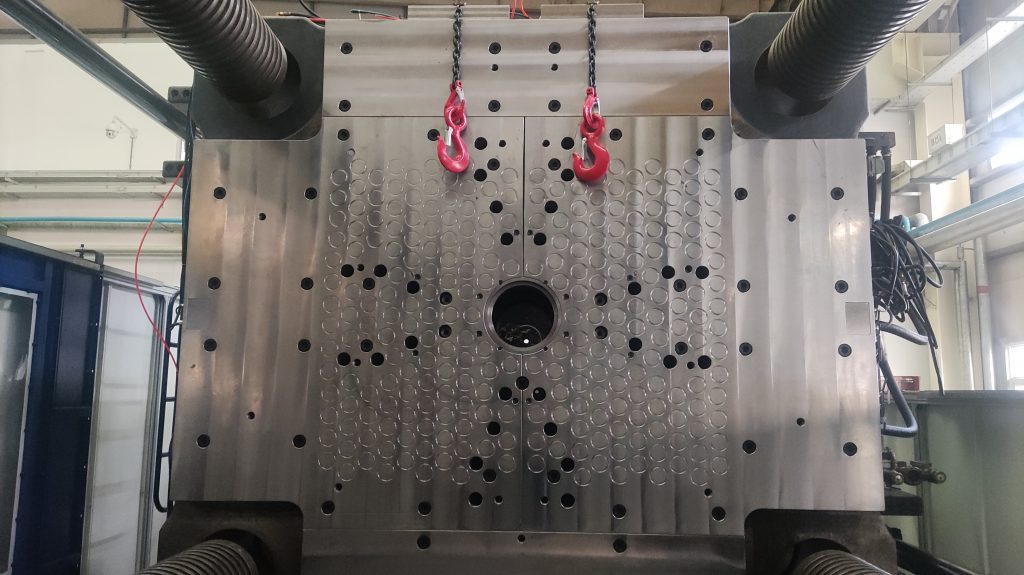

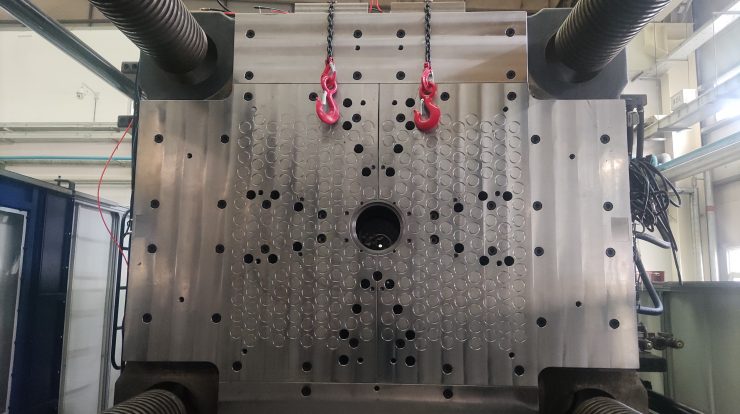

Magnetic clamping platen for quick mold change is an advanced product with the continuous development of science and technology.

Advantage: High efficiency and super time-saving. It can shorten the mold change time to a few minutes. According to incomplete statistics, for small template mold change time is about 1-3 minutes, and large template about 10 minutes.Uniform magnetic force distribution over the mold can ensure mold service life and high product yields, avoiding the deformation of the mold.

Strong adaptability and compatibility with different molds: one set of magnetic templates can meet different needs.

High safety and reliability with a double lock system and automatic safety alerts.

The magnetic platens are steel made, waterproof and oil-proof, with long service life.

Disadvantage:

The first investment is higher and more suitable for medium and large enterprises or manufacturers.

As a professional QMC(Quick Mold Change) System supplier, HVR MAG has been specializing in the manufacturing of electro-permanent magnets. We can provide tailored magnetic quick mold change for different injection molding machines, empowering your efficiency gains.

You are very welcomed to contact us for more detailed information of how to get a quick mold change. Please click here: https://www.hvrmagnet.com/category/magnetic-mold-die-clamping-system-3.html