This is a passage to popularize the magnetic quick mold change knowledge. Nowadays, small batches and multi-species orders lead to frequent mold changes in the injection molding line, which is time-consuming and labor-intensive. A magnetic quick mold change system is the optimal choice to tackle the problem.

Traditionally, it takes 3 hours to change the mold, but it takes only 3 minutes with a magnetic mold clamping system. The magnetic platen for quick mold change is electrically controlled to change the polarity of the permanent magnetic field. And the activation and deactivation process takes only 0.2~2 seconds for the permanent magnets to adsorb the mold. And the working process does not need electricity. The mold-changing process saves time, and effort and significantly reduces labor intensity.

What is the working principle of a 3-minute quick mold change system for an injection molding machine?

When the magnetic platen is magnetized, the magnetic poles of the Alnico magnet change direction after a momentary current is passed in the solenoid coil. And the polarity of the NdFeB Alnico is the same, so the magnetic force is on the surface of the magnetic poles and forms a magnetic circuit with the mold, thus clamping the mold.

In the demagnetization state, the same instantaneous current is passed to change the magnetic pole direction of Alnico, and the magnetic force disappears on the pole surface, thus declamping the mold.

It takes only 0.2~2 seconds to clamp or decamp the mold!

What are the advantages of a magnetic quick mold change system?

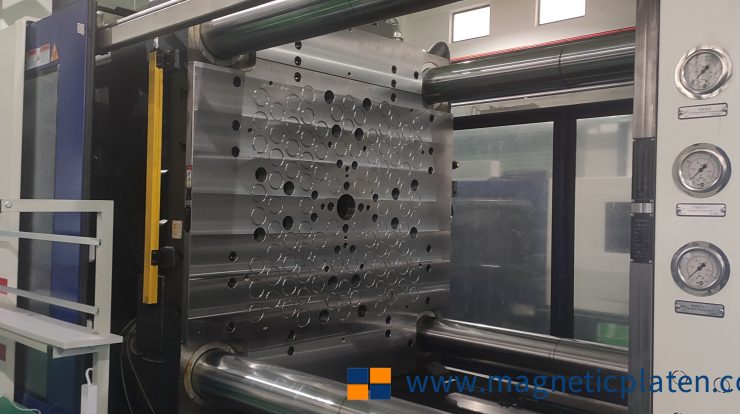

1. The magnetic template does not pick the machine, it is suitable for all types of injection molding machines, covering the configuration of injection molding machines from 50 tons to 4000 tons.

2. A set of magnetic templates can adapt to a variety of injection molds, the magnetic template does not pick the mold, but adapt to a variety of different mold for quick replacement.

3. The magnetic template is water, oil, and corrosion resistant, with a multi-layer waterproof, oil, and corrosion resistant structure, allowing it to be used in the environment with water and oil, and gas.

4. The magnetic template also has the advantages of safety and speed, energy saving, no deformation of the mold, and zero maintenance afterward.

Is the magnetic field radiation of electro-permanent magnets harmful to the human body?

Some customers in the injection molding industry may worry that the magnetic field radiation of the magnetic template will be harmful to the human body. There is no need to worry about it. After the magnetic template is magnetized, the effective range of the magnetic field is within 20mm from the surface of the magnetic platen.

However, people with pacemakers should stay away. Bank cards, watches, cell phones, and other items should also not be near the range within 20mm from the surface of the magnetic platen.

For more magnetic quick mold change knowledge, please visit our website: https://www.magneticplaten.com/ Or, you can send an inquiry to: export@hvrmagnet.com