Plastic Factory Introduced Magnetic Quick Mold Change System

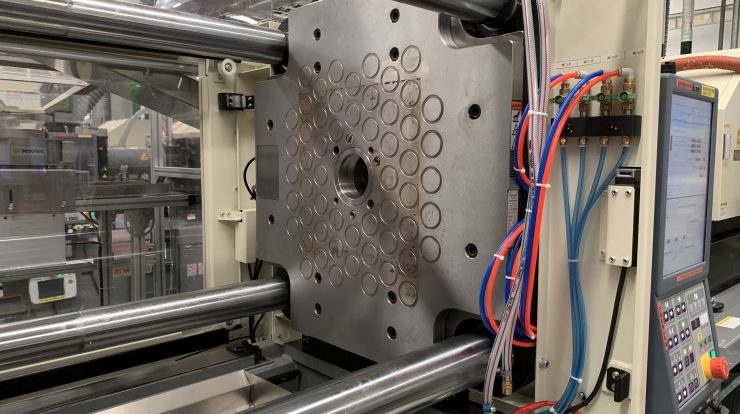

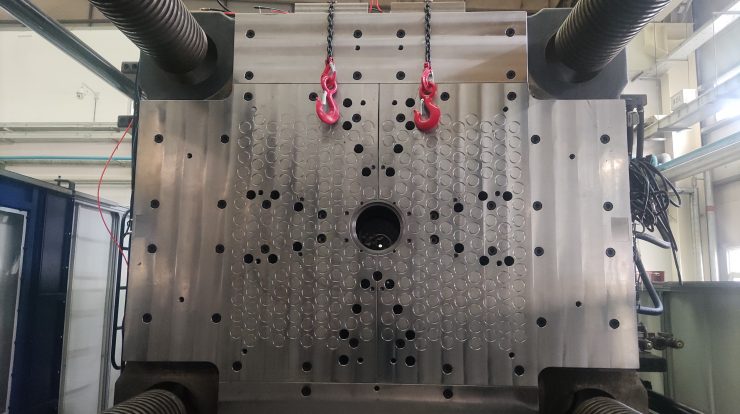

A plastic injection molding factory in Zhongshan City, Guangdong Province introduced 3 sets of magnetic quick mold change systems from HVR MAG. The clamping tonnage of the injection molding machines matched with the 3 sets of magnetic platens is 650 T, 850 T, and 1000 T respectively.

Magnetic Mold Clamping for Medical Injection Mold

Magnetic quick mold change system improves the medical plastic injection molding, according to HVR MAG’s customer from Jiangsu Province.

Clamping Magnet of Quick Mold Change for PMMA Molding

Why magnetic mold clamping quick mold change solution for PMMA injection molding is successful?

Comparison Between Hydraulic and Magnetic Mold Clamping Systems

This article introduces the difference between magnetic and hydraulic quick mold change to provide a reference for efficiency improvement in the injection molding industry.

Tips on Efficient Quick Mold Change Installation for Injection Molding

Regardless of the injection molding production line, mold change is one of the most time-consuming procedures, and a colony of intangible waste is generated during mold changing. In addition,…

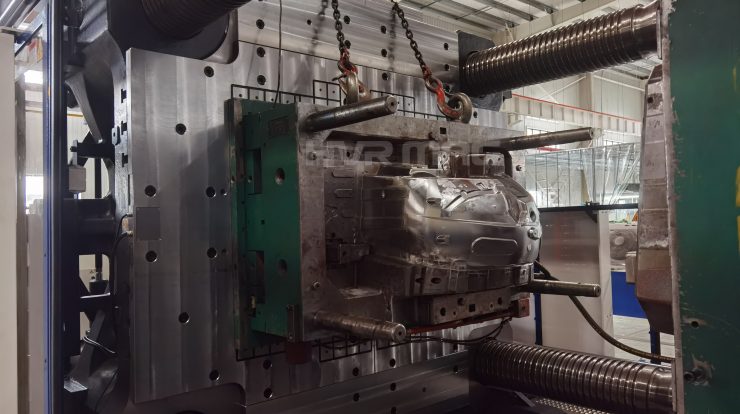

Quick mold change system for bumper manufacturing

This is an application case of quick mold change solution for bumper manufacturing in auto industry. The QMC system was provided by HVR MAG, with efficiency and quality improvement.