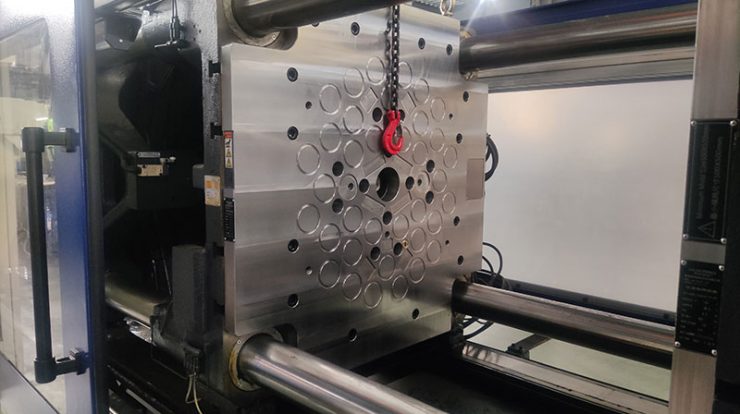

Magnetic Mold Clamping Devices on Injection Molding Machine

Magnetic mold clamping devices offer strong holding force, quick mold changes and improved part quality for injection molding machines.

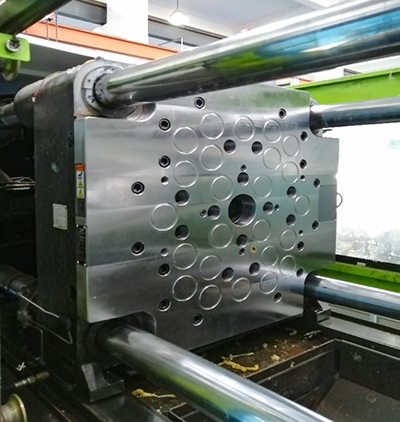

Best Injection Mold Clamps: Magnetic Mold Clamping System

In order to achieve consistent and high-quality results, it is essential to have a reliable and efficient injection mold clamps. The magnetic mold clamping system is widely regarded as the best option of injection mold clamps.

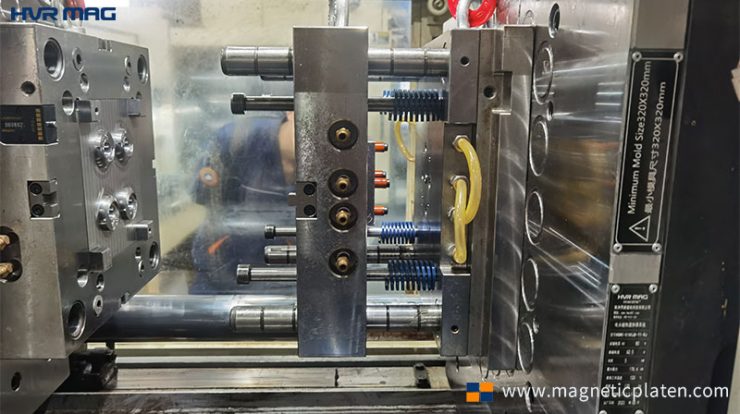

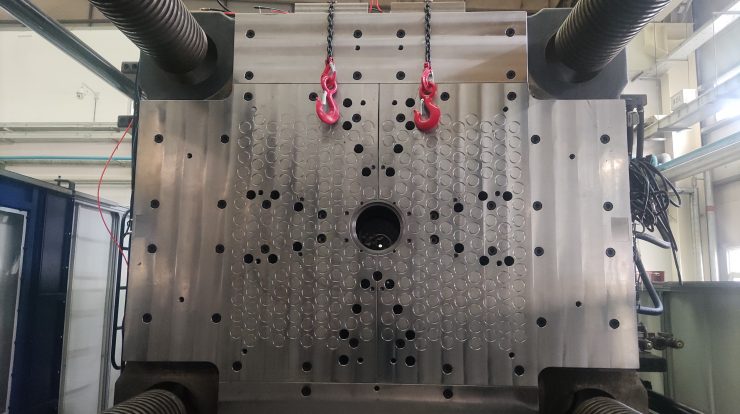

Mold Setting Procedure With Magnetic Mold Clamping System

Mold setting procedure can be fast and simple with magnetic mould clamping system. These are dvantages of the magnetic mold clamping system

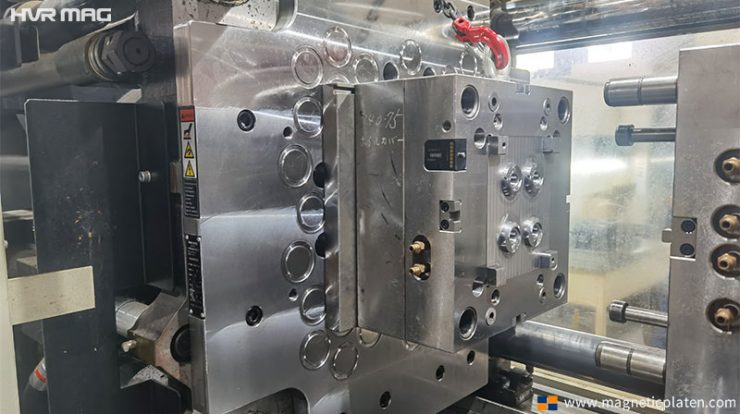

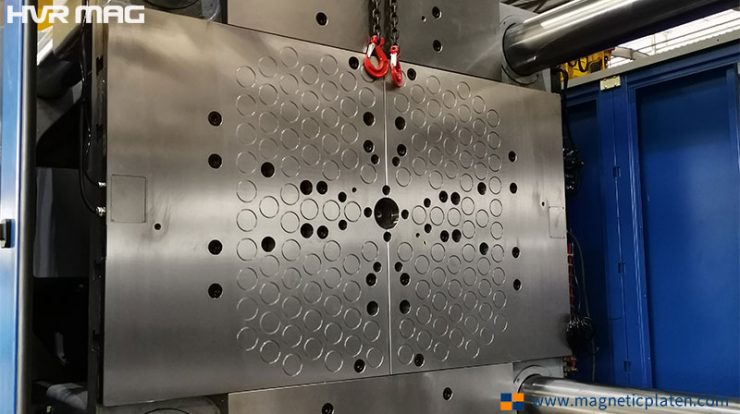

The Best Way of Mold Clamping: Magnetic Plates

Mold clamping is very important for injection moulding machines. Currently, the best way of mold clamping is to use a magnetic plate.

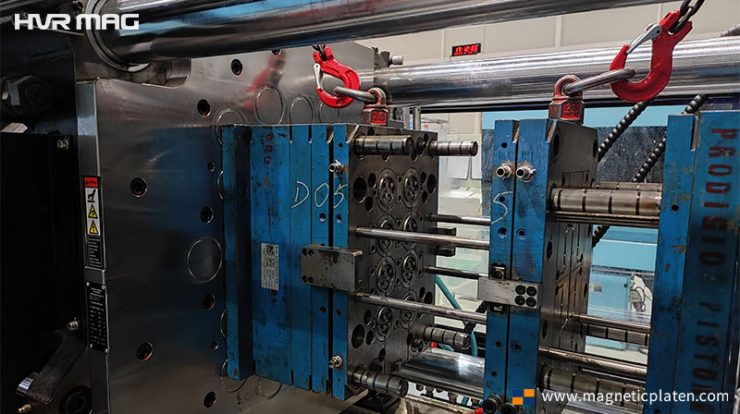

Can Magnetic Mold Clamping System Reduce Mold Change Time?

Magnetic mold clamping system can reducing the mold change cycle time to increase the production capacity of the plastic injection machine.

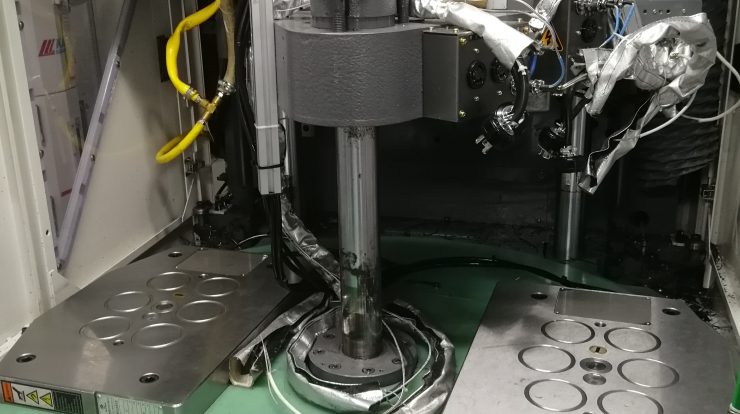

Magnetic Mold Clamping Solution for Vertical Injection Molding Machine

Today I’d like to share with you this application case of small tonnage magnetic mold clamping solution for vertical injection molding machine.

Comparison Between Hydraulic and Magnetic Mold Clamping Systems

This article introduces the difference between magnetic and hydraulic quick mold change to provide a reference for efficiency improvement in the injection molding industry.

Overview on the Application of Injection Molding In Automotive Industry

Injection molding is one of the most commonly used production processes for plastics, as it offers a viable solution for the mass production of high-quality injection automotive parts and components….

How to Calculate the Clamping Force of A Magnetic Platen?

This passage roughly describes the factors that need to be taken into account to calculate the clamping force of a magnetic platen. For example, the size and shape of a magnet, and surface friction, other factors.