Injection molding is a versatile process that is commonly used in manufacturing to produce a wide range of plastic parts. In order to achieve consistent and high-quality results, it is essential to have a reliable and efficient injection mold clamps. The magnetic mold clamping system is widely regarded as the best option of injection mold clamps.

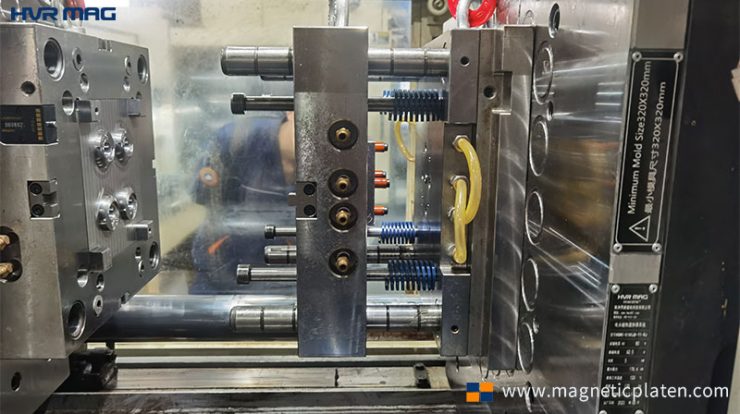

The magnetic mold clamping system uses magnetic force to hold the mold in place during the injection molding process. It consists of two magnetic platens that are mounted on the injection molding machine. The magnetic platens are made from a high-strength magnetic material that creates a strong and consistent magnetic field. The mold is placed between the magnetic platens, and the magnetic force holds the mold in place.

Advantages of Magnetic Mold Clamping System

Faster and Easier to Use

The magnetic mold clamping system is faster and easier to use than traditional mechanical clamping systems. The magnetic clamps can be quickly and easily attached and removed from the mold, which saves time and increases productivity. There are no bolts or clamps to install or remove. Which eliminates the need for tools and reduces the risk of damage to the mold.

More Versatile

Another advantage of the magnetic mold clamping system is that it is more versatile than traditional clamping systems. The magnetic force can be adjusted to accommodate different mold sizes and shapes, which makes it ideal for use with a wide range of injection molding applications. Additionally, the magnetic clamps can be used with molds that have uneven surfaces or irregular shapes, which is not possible with traditional clamping systems.

Safer

The magnetic mold clamping system is also safer than traditional clamping systems. There are no moving parts that can come into contact with the mold, which reduces the risk of damage to the mold and the injection molding machine. Additionally, the magnetic force is constant and does not require any adjustments during the injection molding process, which further reduces the risk of accidents and injuries.

More Cost-Effective

Finally, the magnetic mold clamping system is more cost-effective than traditional clamping systems. The magnetic clamps are made from high-strength magnetic material, which is durable and long-lasting. This means that they require less maintenance and replacement than traditional clamps, which saves money in the long run.

Conclusion

In conclusion, the magnetic mold clamping system is the best injection mold clamp due to its speed, versatility, safety, and cost-effectiveness. It is an essential component of any injection molding operation that requires consistent and high-quality results. By using a magnetic mold clamping system, manufacturers can increase productivity, reduce costs, and improve the overall quality of their products.

As a professional manufacturer of magnetic quick change systems, HVR MAG is committed to providing quality products and services. If you need a highly cost effective magnetic mold clamping system for your plastic injection molding machine, feel free to contact us.