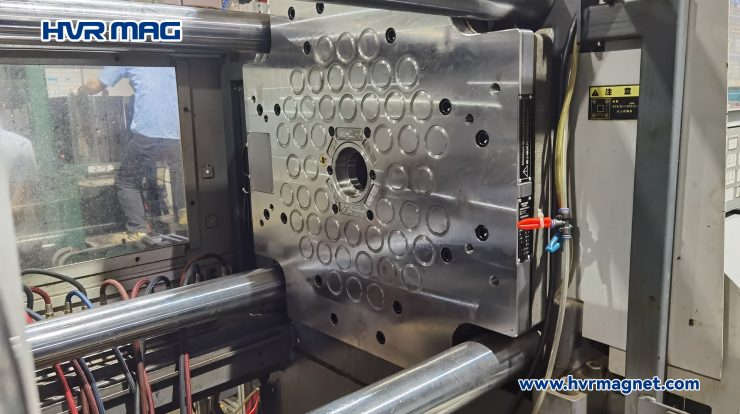

Advantages of Magnetic Platens with Circular Poles

Why do some magnetic quick mold change systems use magnetic platens with circular poles? This article will answer this question. Enhance the Versatility of Magnetic Platens in Mold Size Accommodation…

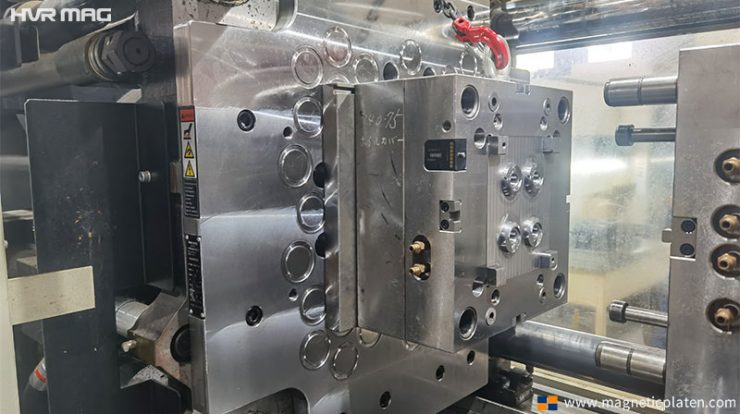

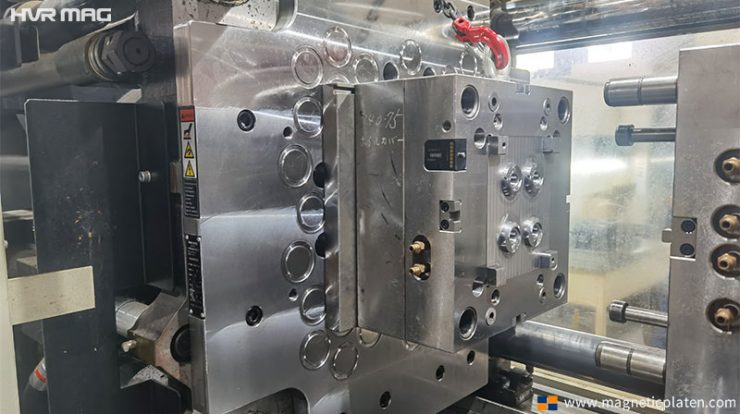

How Magnetic Platens Position the Mold in a Quick Mold Change System?

Among the various components of a magnetic quick mold change system, the magnetic platens play a crucial role in precisely positioning the mold for optimal performance. Let’s delve deeper into…

Is There Electric Hazard with Magnetic Quick Mold Change System?

The advent of magnetic quick mold change system revolutionized the mold clamping process in plastics injection molding, offering unparalleled efficiency and safety. However, concerns regarding electric hazards with these systems…

Recommendation on How to Clean and Maintain Magnetic Platen

Magnetic platen is used as mold clamping system in injection molding process. The system allows for precise and uniform clamping of molds, offering the advantages of quick mold changeover. Cleaning…

Understand How Magnetic Platen Saves Time

Injection molding is a widely used manufacturing process in which molten material is injected into a mold cavity, resulting in the production of various products. The efficiency and productivity of…

Magnetic Platen: Making Injection Molding More Eco-Friendly

Injection molding machines consume a considerable amount of energy during operation. Implementing energy-efficient equipment, optimizing production processes, and using energy-saving technologies can significantly reduce the energy consumption associated with injection…

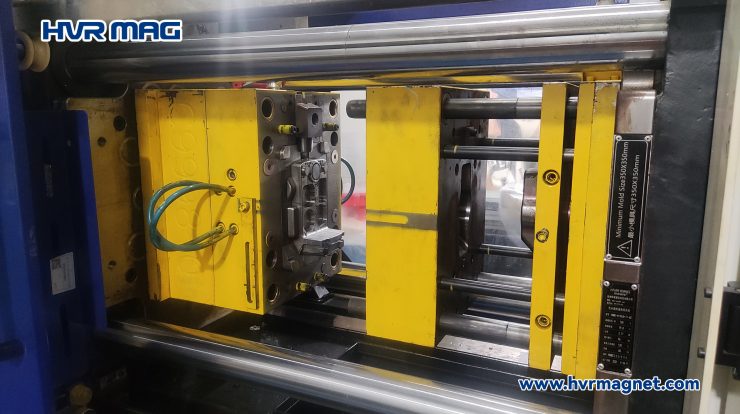

Understand How Injection Molding Machine Uses Magnetic Clamping System

Magnetic clamping system is essential in the injection molding industry, offering numerous benefits despite certain operational challenges. If your company has not yet adopted a magnetic clamping system, it is…

Types of Mold Clamping for Injection Molding Machine

When it comes to injection molding machines, the clamping mechanism plays a crucial role in securely holding the mold during the injection process. Three commonly used clamping methods are hydraulic…

Magnetic Templates for Injection Mould Clamping

Injection mould clamping plays a crucial role in the manufacturing industry, ensuring precise and secure positioning of moulds during the production process. To enhance efficiency and accuracy in this operation,…

Will Clamping Method Affect the Quality of Product?

Plastic injection molding is a highly versatile process to produce complex shapes and parts with a high degree of accuracy and consistency. Injection molding machines have varies of size and…