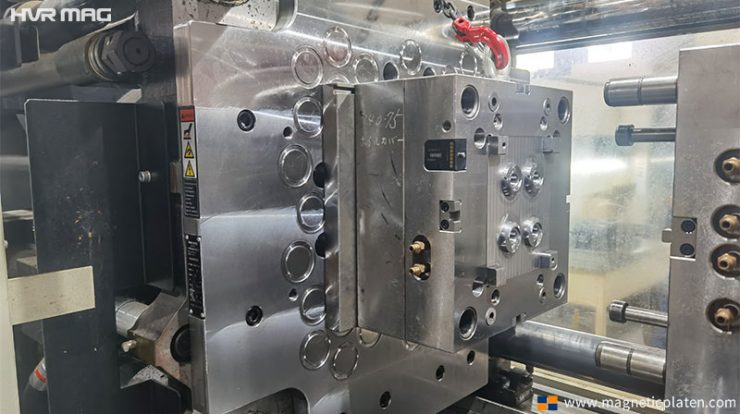

Magnetic mold clamping devices are a type of clamping system used in injection molding machines. They work by using powerful magnets to hold the mold in place during the injection and cooling process. In this blog, we will discuss the features and advantages of magnetic clamping devices on injection molding machines.

Features of Magnetic Mold Clamping Devices on Injection Molding Machines

Strong holding force: Magnetic clamping devices providing a strong and reliable clamping force.

Quick and easy mold changes: Magnetic clamping devices allow for quick and easy mold changes. Reducing downtime and increasing productivity.

Improved safety: Magnetic clamping devices eliminate the need for manual clamping, reducing the risk of injury to operators.

Reduced maintenance: Magnetic clamping devices require less maintenance than traditional hydraulic or mechanical clamping systems. Reducing maintenance costs and increasing uptime of the machine.

Improved part quality: Magnetic clamping devices provide a more uniform clamping force, resulting in improved part quality and consistency.

Advantages of Magnetic Clamping Devices on Injection Molding Machines

Faster cycle times: Magnetic clamping devices can reduce cycle times by up to 50%, increasing productivity and reducing costs.

Energy efficiency: Magnetic clamping devices are more energy-efficient than hydraulic or mechanical clamping systems. It can reducing energy consumption and operating costs.

Environmentally friendly: Magnetic clamping devices do not require hydraulic oil or other fluids, reducing the environmental impact of injection molding machines.

Increased flexibility: Magnetic clamping devices can be used with a wide range of mold sizes and shapes, providing greater flexibility in production.

Cost-effective: Although the initial cost of magnetic clamping devices may be higher than traditional clamping systems, the long-term cost savings in terms of reduced maintenance, increased productivity, and energy efficiency make them a cost-effective option for injection molding machines.

Conclusion

Magnetic mold clamping devices offer a range of features and advantages for injection molding machines, including strong holding force, quick and easy mold changes, improved safety, reduced maintenance, and improved part quality. They also offer advantages in terms of faster cycle times, energy efficiency, environmental friendliness, increased flexibility, and cost-effectiveness. By using magnetic clamping devices on injection molding machines, manufacturers can improve productivity, reduce costs, and produce high-quality parts with greater consistency.

HVR MAG is a manufacturer of magnetic clamping devices and we always insist on providing our customers with quality products and services. Feel free to contact us.