Magnetic platen is used as mold clamping system in injection molding process. The system allows for precise and uniform clamping of molds, offering the advantages of quick mold changeover. Cleaning is vital to maintain its efficiency and longevity. In this article, we will provide a step-by-step guide on how to clean and maintain your magnetic platen.

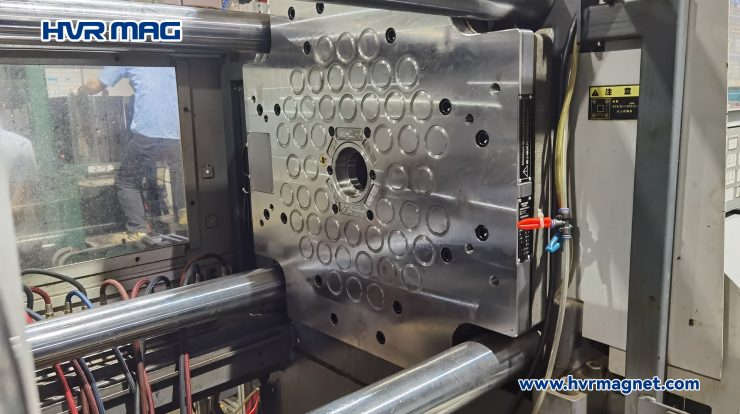

Introduction to HVR Magnetic Platen

The HVR magnetic platen adopts an integrated design, with a stable structure that will not be damaged by accidental impacts. It has no moving parts inside, which do not generate too much heat, able to work reliably for a long time. Strengthening the maintenance and care of this product on a daily basis can help it remain in normal operating condition for an extended period.

Overview of Magnetic Platen Cleaning and Maintenance

The working environment must be fireproof, explosion-proof, dust-proof, and resistant to strong electromagnetic fields. Platens should be placed in a ventilated area, preventing liquids and metal particles from entering the controller.

Regularly clean the dust and oil stains on the operating box, terminals, buttons, and magnetic pole.

How Often Should You Clean Your Magnetic Platen?

Use mold cleaner to clean the surface of the magnetic poles each time the mold is changed. Daily cleaning of dust and oil at the operating box, terminals, and buttons.

How Often Should You Check Your Magnetic Platen?

It is recommended that users conduct a monthly inspection of the buttons, indicator lights, terminal blocks, and connection lines of the electric permanent magnet controller, and a semi-annual check of the resistance and insulation values of the platen. Before inspection, disconnect the connection lines between the controller and the platen.

Is Removable Magnetic Pole Easier to Maintain?

Removable poles expand and contract more frequently and the insulation is more likely to be damaged. They are susceptible to oxidation and have lower reliability and durability.

Conclusion

Proper cleaning and maintenance are essential for the optimal performance and longevity of an Electro Permanent Magnetic mold clamping system. By following the tips outlined in this guide, you can ensure that your EPM system remains in top condition, providing efficient and reliable mold clamping solutions for your manufacturing operations. For more information, please contact HVR MAG at export@hvrmagnet.com