Injection mould clamping plays a crucial role in the manufacturing industry, ensuring precise and secure positioning of moulds during the production process. To enhance efficiency and accuracy in this operation, magnetic templates have emerged as a valuable tool. In this blog, we will explore the benefits of magnetic templates for injection mould clamping. We will highlighting how they streamline the process, improve productivity, and deliver cost-effective solutions.

The Benefits of Magnetic Templates for Injection Mould Clamping

Simplified Setup and Alignment

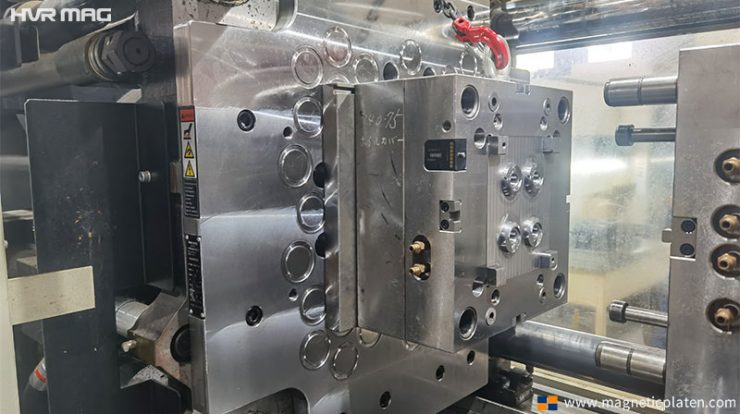

One of the key advantages of magnetic templates is their ability to simplify the setup and alignment process. These templates are designed with a grid of magnetic poles, allowing for easy and accurate positioning of moulds on the clamping machine. The magnetic force securely holds the mould in place, eliminating the need for complex manual adjustments or additional tools. The simplified setup and alignment save valuable time, reduce human error, and enhance overall efficiency in injection mould clamping.

Enhanced Stability and Precision

Magnetic templates provide superior stability and precision during the clamping process. The powerful magnetic force ensures a strong grip on the mould, preventing any unwanted movement or shifting. This stability is particularly beneficial when dealing with intricate or complex moulds that require precise alignment. By minimizing the risk of misalignment or slippage, magnetic templates contribute to higher quality end products, reducing the need for rework and enhancing overall productivity.

Versatility and Adaptability

Magnetic templates offer versatility and adaptability, making them suitable for a wide range of injection moulding applications. The magnetic poles on the template can be easily adjusted to accommodate different mould sizes and shapes. This flexibility eliminates the need for multiple clamping devices and reduces setup time between mould changes. The adaptability of magnetic templates allows manufacturers to optimize their production processes, handle various moulds efficiently, and respond quickly to changing production requirements.

Increased Safety

Safety is of paramount importance in any manufacturing operation, and magnetic templates contribute to a safer working environment. The secure magnetic grip provided by these templates minimizes the risk of accidents or injuries caused by moulds dislodging during the clamping process. Additionally, the elimination of manual adjustments reduces the exposure of operators to potential hazards, such as pinch points or heavy lifting. By prioritizing safety, magnetic templates enhance employee well-being and promote a more productive workplace.

Cost Savings

Magnetic templates offer cost-effective solutions for injection mould clamping. The simplified setup process and increased efficiency result in reduced downtime and faster production cycles. The precise alignment and stability provided by magnetic templates also minimize material waste and improve mould longevity. By optimizing the clamping process, manufacturers can achieve higher production volumes, reduce operational costs, and enhance overall profitability.

Easy Maintenance

Maintaining magnetic templates is relatively straightforward. Regular cleaning and inspection to remove any debris or contaminants from the magnetic surfaces ensure optimal performance. Additionally, checking for any signs of wear or damage allows for timely repairs or replacements, avoiding any potential disruptions in the clamping process. The ease of maintenance associated with magnetic templates contributes to their long-term reliability and cost-effectiveness.

Conclusion

Magnetic templates have revolutionized injection mould clamping, offering numerous benefits that streamline the process and improve productivity. With simplified setup and alignment, enhanced stability and precision, versatility and adaptability, increased safety, cost savings, and easy maintenance, these templates have become an essential tool in the manufacturing industry. By incorporating magnetic templates into their injection moulding operations, manufacturers can optimize their processes, reduce costs, and achieve higher quality end products consistently.

HVR MAG is a professional manufacturer of magnetic templates, our products have many cooperation cases, not only can be used in regular injection moulding machines, but also can be used in two-colour injection moulding machines, die-casting machines and other machines that need to fix the moulds or die accurately. Welcome to contact us for more details.