Efficient and secure die clamping is crucial in press machine operations, as it directly impacts productivity and safety. Traditional methods of die clamping often involve time-consuming manual processes. However, with the advent of magnetic die clamping systems, businesses can streamline their operations and enhance overall efficiency. In this blog, we will introduce magnetic quick die clamping for press machines and explore the advantages it offers.

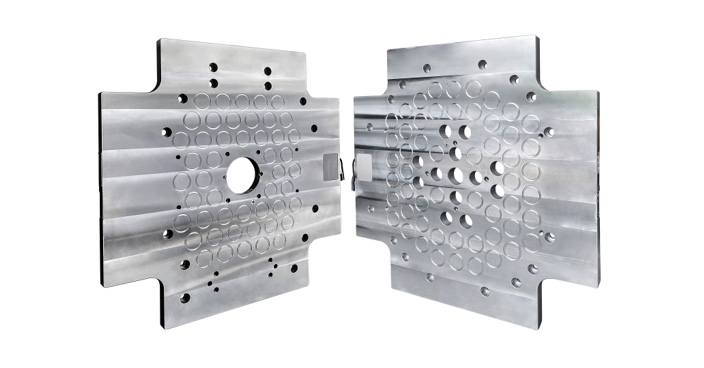

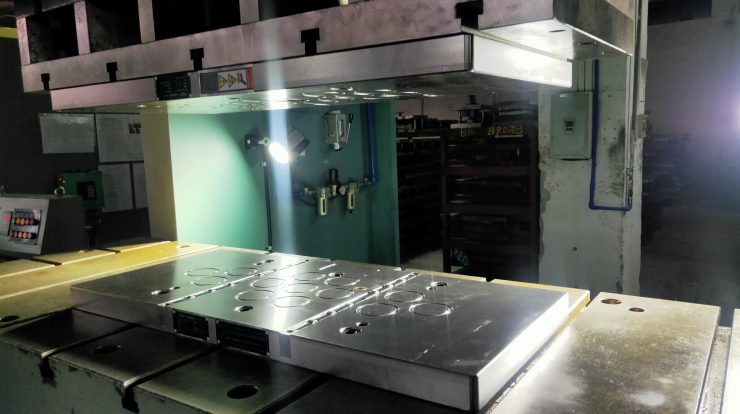

Understanding Magnetic Die Clamping: Magnetic quick die change systems utilize powerful permanent magnets to securely clamp dies onto press machines. These systems eliminate the need for manual clamping, bolts, or other time-consuming procedures. By leveraging magnetic force, dies can be quickly positioned, securely clamped, and easily released, significantly reducing setup time and improving operational efficiency.

Advantages of Magnetic Die Clamping for Press Machines

- Rapid Die Changeovers: Magnetic die change systems enable swift die changeovers, minimizing downtime between production runs. The magnetic force allows for quick attachment and detachment of dies, eliminating the need for complex manual adjustments or tools.

- Enhanced Safety: Magnetic die clamping systems enhance operator safety by eliminating the risk of accidents associated with manual handling of heavy dies. With magnetic clamping, operators no longer need to lift or maneuver dies manually, reducing the risk of strain or injuries.

- Precise Alignment: Magnetic die change systems ensure precise alignment of dies, minimizing the risk of misalignment or errors during the setup process. This precision saves time and avoids potential quality issues caused by improper die positioning.

- Versatility: These systems can be customized to accommodate various die sizes and shapes, making them suitable for a wide range of press machine applications. They offer flexibility in adapting to different production requirements, further enhancing operational efficiency.

- Improved Productivity: Magnetic die change systems significantly reduce setup time, allowing for more frequent die changes and increased production output. This improved productivity translates into cost savings and enhanced competitiveness.

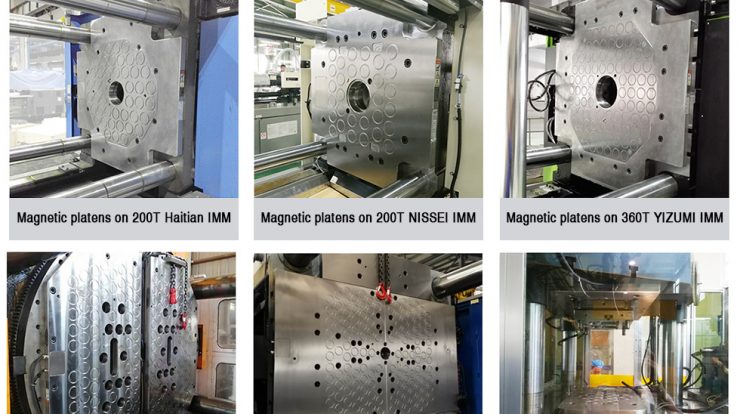

Implementing Magnetic Plates

- System Integration: Ensure proper integration of the magnetic die clamping system with your press machine. Consult with the manufacturer or a qualified expert to ensure compatibility and proper installation.

- Operator Training: Provide comprehensive training to operators on the correct operation and maintenance of the magnetic die change system. This training should cover safety protocols, system controls, and troubleshooting techniques.

- Regular Maintenance: Conduct routine inspections and maintenance of the magnetic clamping components. This includes cleaning, checking for any damage or wear, and replacing components as necessary. Regular maintenance maximizes the system’s longevity and performance.

- Workflow Optimization: Streamline the die changeover process by optimizing the workflow. Identify and eliminate any unnecessary steps or potential bottlenecks to minimize downtime and maximize productivity. Efficient workflow planning ensures smooth die changeovers and reduces overall production cycle time.

Conclusion: Magnetic die clamping systems have revolutionized the die changing process in press machines, offering significant time savings and operational efficiencies. Leveraging the power of magnets, these systems enable rapid die changeovers, enhanced safety, precise die alignment, and increased productivity. By implementing magnetic die change systems and following the tips provided, businesses can optimize setup time, improve productivity, and enhance overall operational performance. Embrace the advantages of magnetic die clamping and unlock the potential for seamless and efficient die clamping in your press machine operations.

HVR MAG provides quick die change system for press machine and quick mold change system for IMM. If you are looking for the solution to improve die or mold changing efficiency, welcome to visit the website or contact us.