Addressing High Mold Temperature in Magnetic Mold Clamping Systems

In the realm of injection molding, the efficiency and reliability of magnetic mold clamping systems are paramount. However, like any machinery, they can encounter challenges, particularly when mold temperatures soar…

Magnetic Platen: Making Injection Molding More Eco-Friendly

Injection molding machines consume a considerable amount of energy during operation. Implementing energy-efficient equipment, optimizing production processes, and using energy-saving technologies can significantly reduce the energy consumption associated with injection…

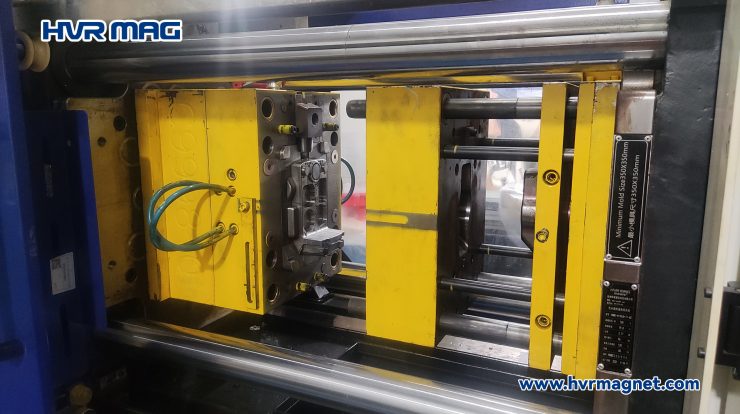

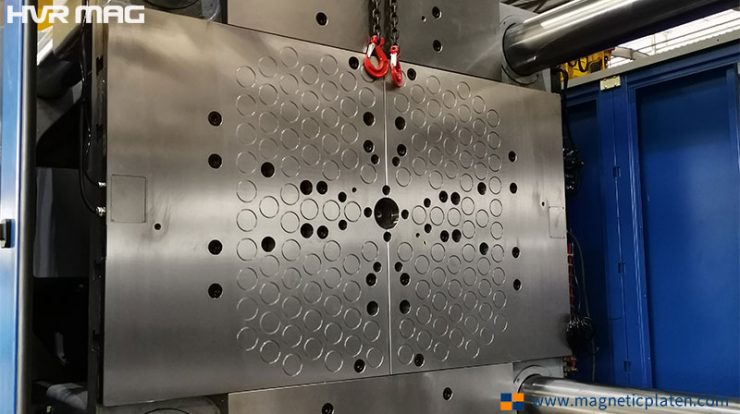

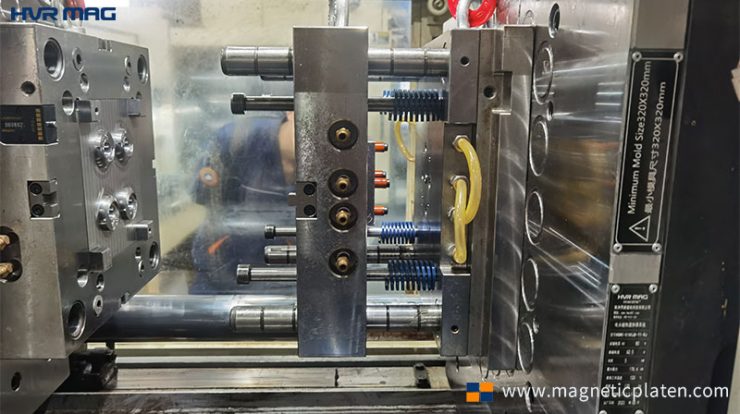

Magnetic Templates for Injection Mould Clamping

Injection mould clamping plays a crucial role in the manufacturing industry, ensuring precise and secure positioning of moulds during the production process. To enhance efficiency and accuracy in this operation,…

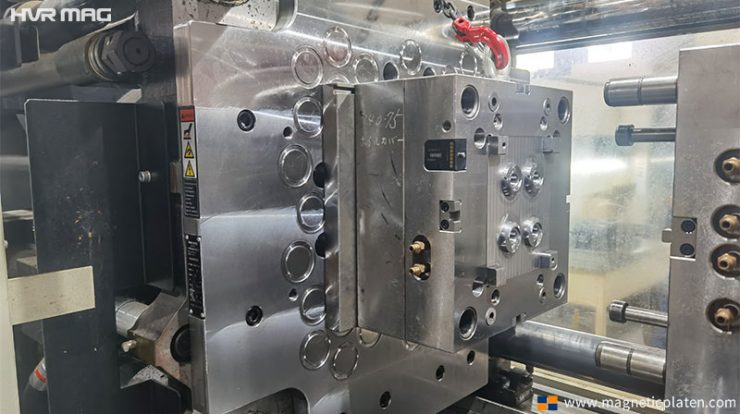

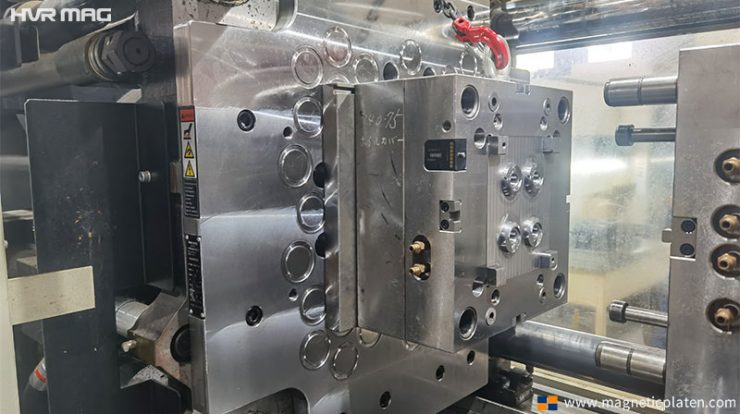

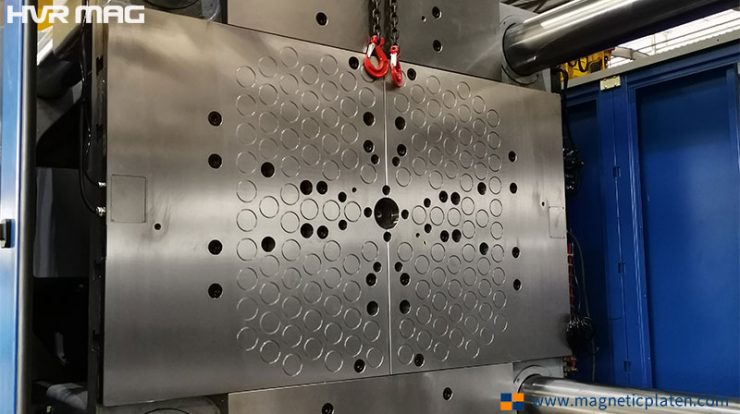

How to Reduce Mould Change Time with Magnetic Plates

Efficient mold changeovers are critical in industries. How to reduce mould change time with magnetic mold change systems?

Will Clamping Method Affect the Quality of Product?

Plastic injection molding is a highly versatile process to produce complex shapes and parts with a high degree of accuracy and consistency. Injection molding machines have varies of size and…

Proper Maintenance Tips for Magnetic Templates in HQMC

Magnetic templates play a crucial role in quick mold change systems, ensuring efficient and precise mold positioning. To maximize their lifespan and performance, proper maintenance is essential. In this blog, we will provide valuable tips on how to properly maintain magnetic templates in quick mold change systems.

Best Injection Mold Clamps: Magnetic Mold Clamping System

In order to achieve consistent and high-quality results, it is essential to have a reliable and efficient injection mold clamps. The magnetic mold clamping system is widely regarded as the best option of injection mold clamps.

The Best Way of Mold Clamping: Magnetic Plates

Mold clamping is very important for injection moulding machines. Currently, the best way of mold clamping is to use a magnetic plate.

Magnetic Clamping Device Design Principle

The magnetic clamping device can reduce mould change time and increase productivity. Here I will introduce you to the design principle of it.