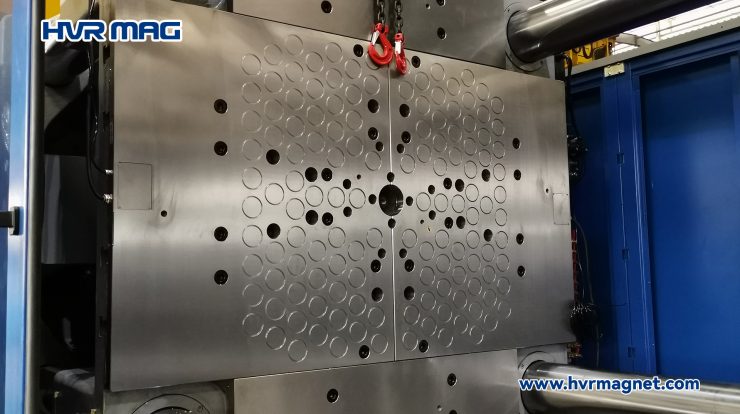

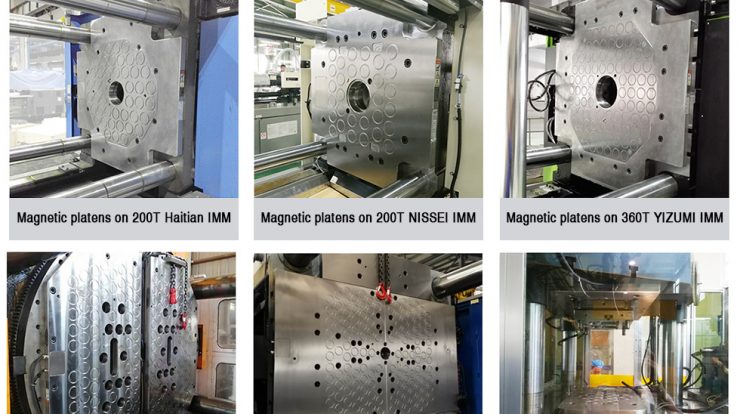

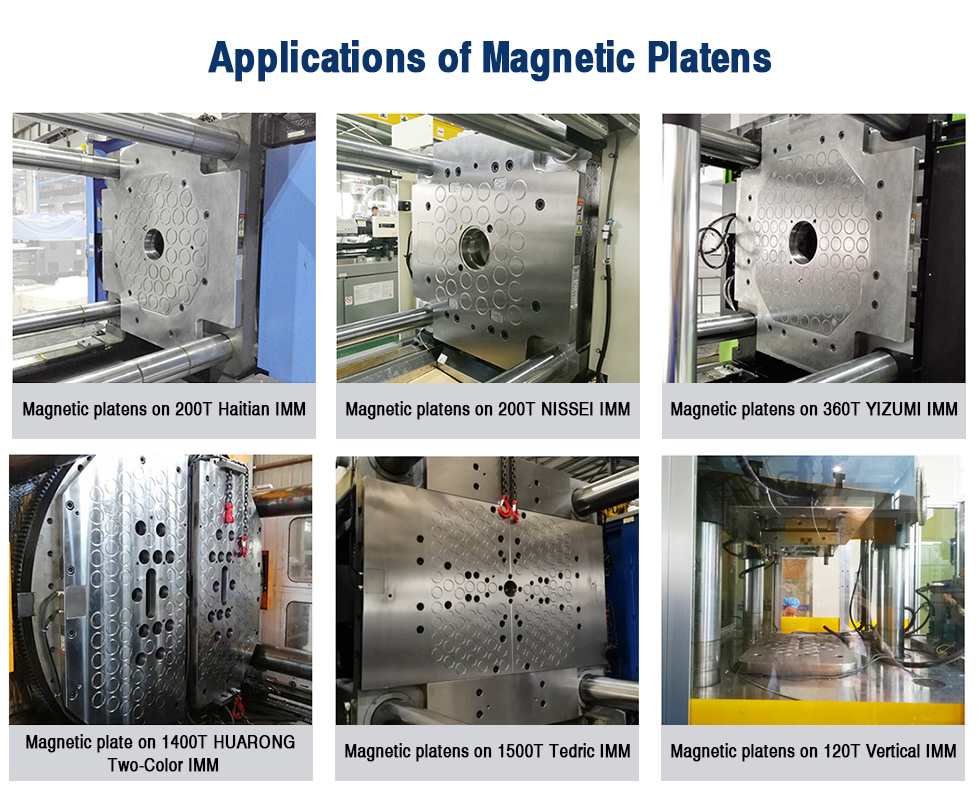

Magnetic platens are frequently used for quick mold change in injection molding machines, quick die change for stamping presses in industry, due to their efficient changeovers. Companies benefited a lot from the application of magnetic platen system, compared to conventional mold/die change procedures. Since mentioned, some may wonder how do magnetic platens work? Well, it all goes back to the core part of a platen, the magnets inside. HVR MAG can lead you through it.

Magnetic platens manufactured by HVR MAG, allow very fast mould/die changing because there are no clamps to remove and refit. They can clamp the mold/die instantly with strong electrically energized permanent magnets (Neodymium magnet, Alnico magnet). The electro-permanent magnetic technology utilized in the magnetic platens, does not use power once energized so a loss of power does not cause a loss of holding force. Nor does it require electricity during the production cycle of the machine. For detailed information about the magnetic clamping process, please refer to the following working principle of magnetic platens.

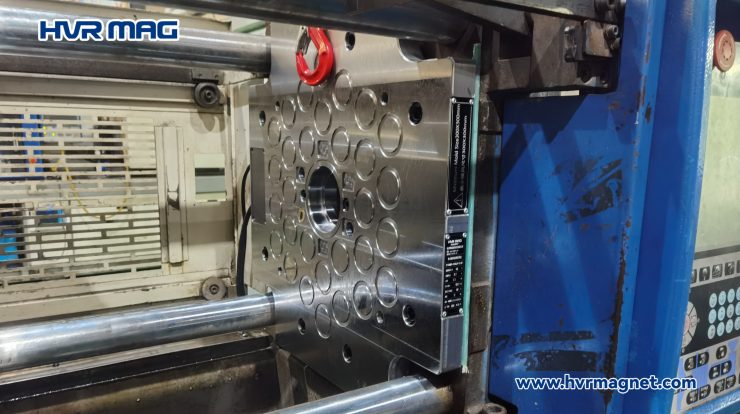

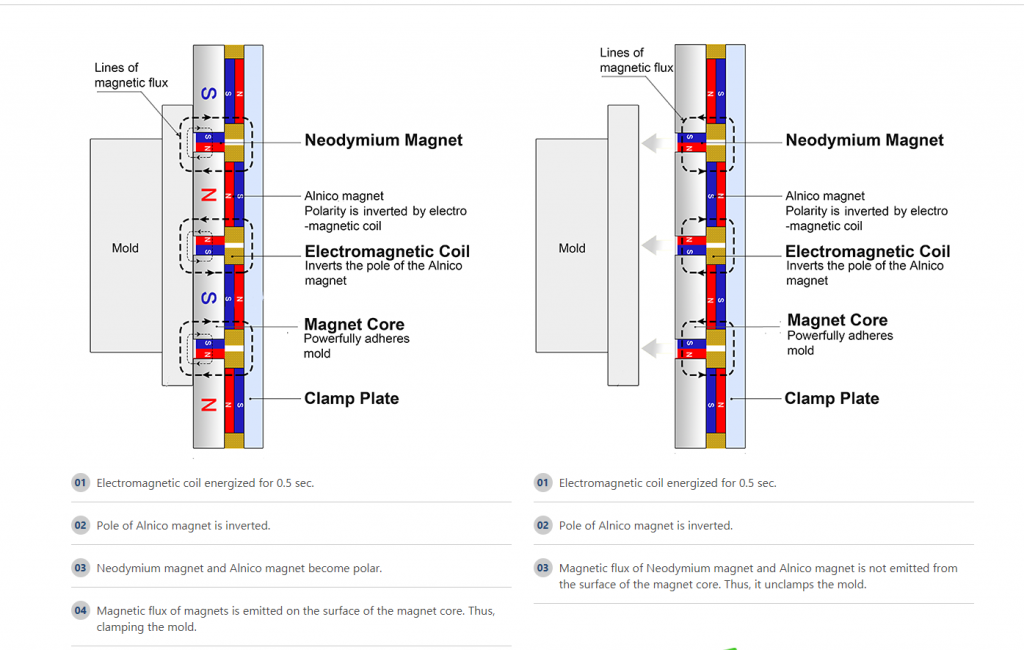

Magnetization

During the MAG phase, the magnetic flux is outside of the magnetic platen safely clamping the mold/die. When the magnetic platen system is activated, a short burst of electric current temporarily changes the polarity of the magnet so that the magnetic field enters into the mold/die for clamping – mold/die can be adhered instantly (within several seconds). No energy is required to maintain the polarity of the magnetic flux in either configuration.

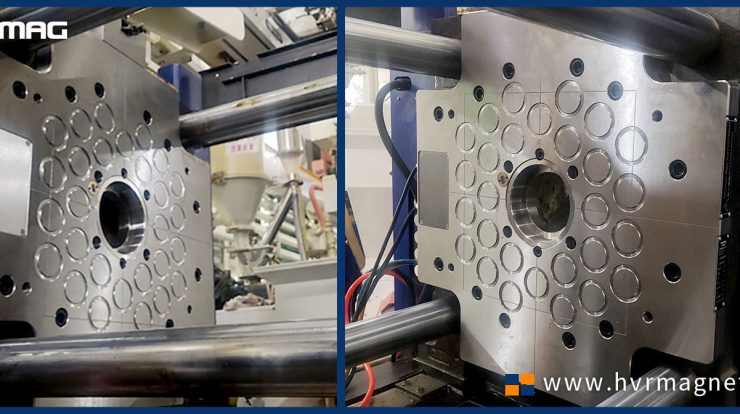

Demagnetization

During the DEMAG phase, the magnetic flux is drawn back inside of the magnetic platen. The magnetic field is disengaged from it for unclamping – mold/die can be detached instantly (within several seconds). This DEMAG Cycle leaves no residual magnetism in the mold/die allowing it to be removed easily from the machine for changeover.

To sum up, an instantaneous electrical charge can energize the magnetic platen system. Once energized, the magnetic platens cannot lose this magnetism unless the power is switched ON. Even during a power failure, the system remains operative, with constant clamping force. So a power cut cannot cause the mould/die to fall.