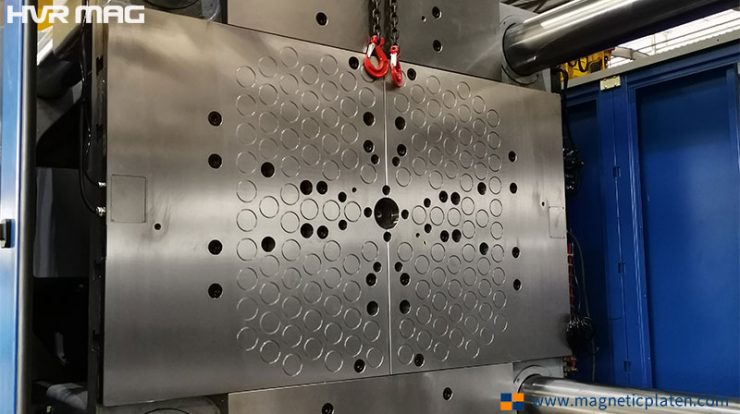

Advantages of Magnetic Platens with Circular Poles

Why do some magnetic quick mold change systems use magnetic platens with circular poles? This article will answer this question. Enhance the Versatility of Magnetic Platens in Mold Size Accommodation…

How Do Magnetic Platens Work Under High Temperature?

Magnetic clamping system has emerged as a useful tool to enhance efficiency and accuracy in injection molding process. This system comprises two sets of electro permanent magnetic platens, with one…

Magnetic Templates for Injection Mould Clamping

Injection mould clamping plays a crucial role in the manufacturing industry, ensuring precise and secure positioning of moulds during the production process. To enhance efficiency and accuracy in this operation,…

How to Reduce Mould Change Time with Magnetic Plates

Efficient mold changeovers are critical in industries. How to reduce mould change time with magnetic mold change systems?

Will Clamping Method Affect the Quality of Product?

Plastic injection molding is a highly versatile process to produce complex shapes and parts with a high degree of accuracy and consistency. Injection molding machines have varies of size and…

Magnetic Mold Clamping Devices on Injection Molding Machine

Magnetic mold clamping devices offer strong holding force, quick mold changes and improved part quality for injection molding machines.

SMED with Magnetic Clamping Devices

Mould or die change is important in injection moulding industry, magnetic clamping devices can help you achieve Single-Minute Exchange of Die

5 Advantages of HVR Quick Die Change System

There are 3 commen types of quick die change system. And HVR provide the magnetic type. What’s the advantage of magnetic quick die change system?

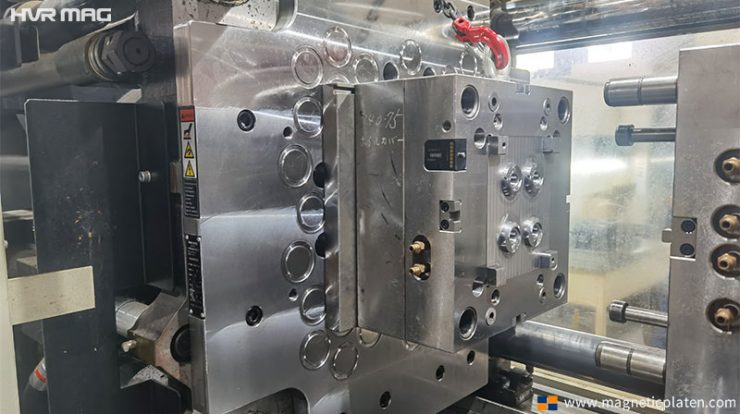

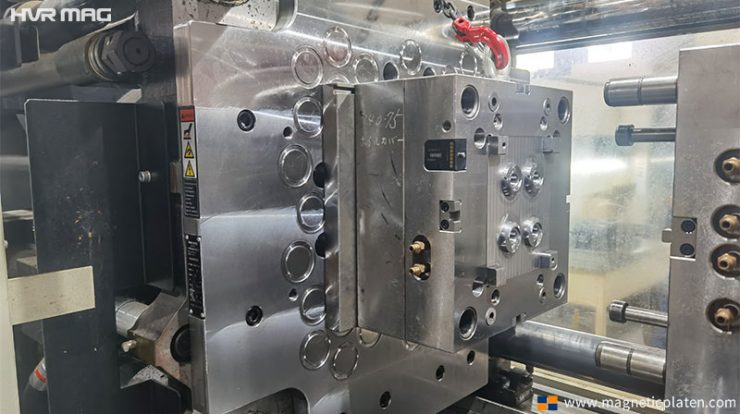

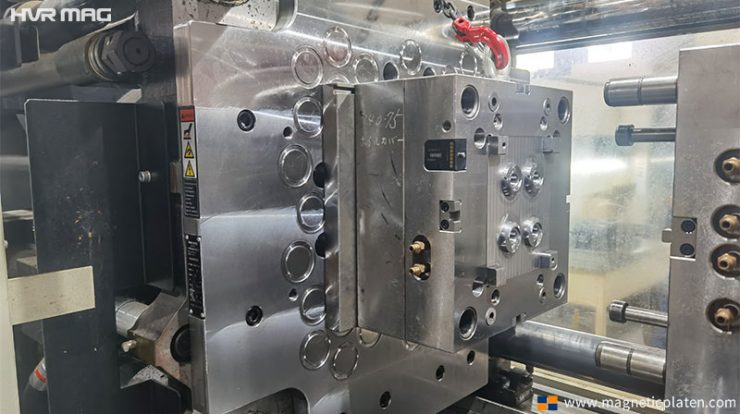

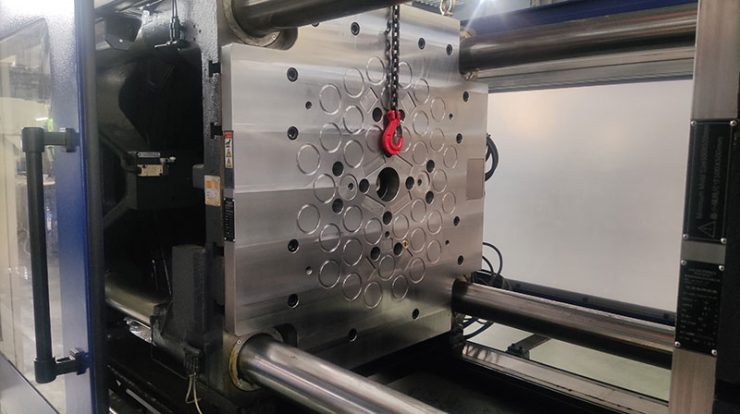

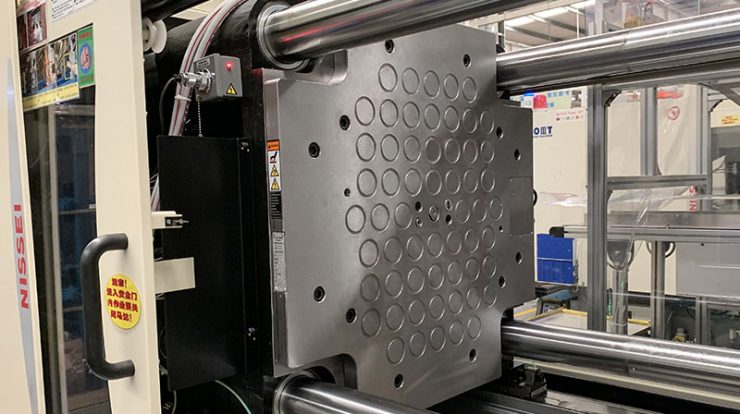

Plastic Factory Introduced Magnetic Quick Mold Change System

A plastic injection molding factory in Zhongshan City, Guangdong Province introduced 3 sets of magnetic quick mold change systems from HVR MAG. The clamping tonnage of the injection molding machines matched with the 3 sets of magnetic platens is 650 T, 850 T, and 1000 T respectively.