Regardless of the injection molding production line, mold change is one of the most time-consuming procedures, and a colony of intangible waste is generated during mold changing. In addition, the traditional mold changing process relies on the master’s experience to set molds and adjust them. But the job is relatively dangerous and tiring. How to improve your efficiency in mold changing process? HVR MAG will give you some tips on efficient quick mold change installation for plastic injection molding:

Perfect pre-work planning

Generally, the mold changing process can be divided into operations before the shutdown, operations during the shutdown, and operations after the shutdown.

Operations before shutdown: preparations of mold change tools, mold transportation…

Operation during shutdown: mold positioning, takeover operations…

Operations after shutdown: tool homing, floor cleaning…

Perfect planning is to reduce work time and continuously improve the operation process.

Standardize and simplify mold change operations

Standardize the size of mold plate thickness to facilitate the rapid positioning and fixing of the mold and the advantages of convenient transportation.

Use a suitable system to assist with changing processes and reduce downtime.

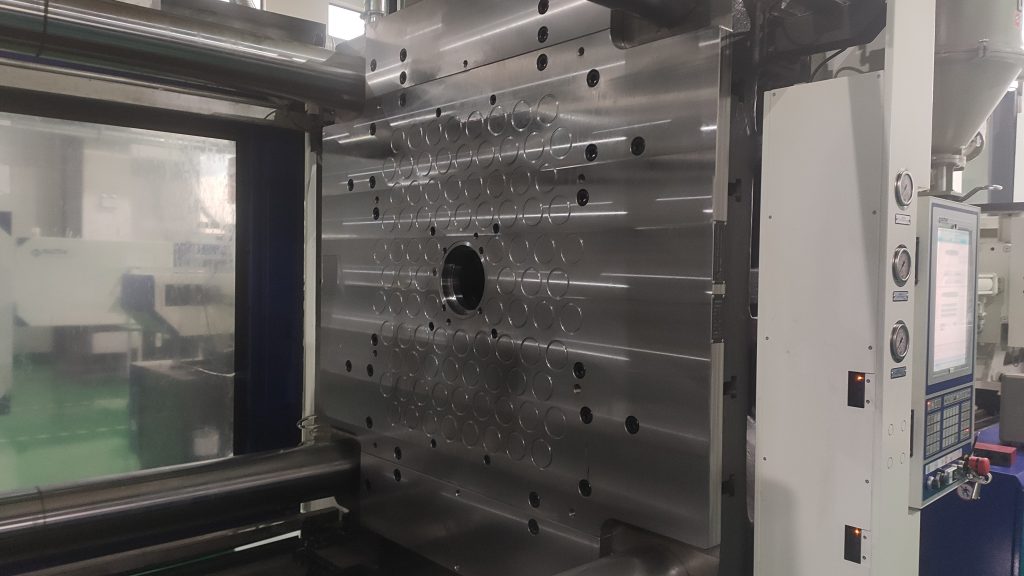

The work can use the quick mold change system to reduce downtime. For example, the molds were previously fixed by screws; now, hydraulic clamps or magnetic plates are used to replace the screws, significantly reducing the time to disassembly or restoring the mold in the machine. Using the quick mold change system can standardize operations during downtime and provide a safer process environment for employees. HVR aims to offer our customers the most competitive magnetic platen.

Training personnel to change molds

Gradually move towards the fully automated mold changing process

It’s the trend to use robots or mold-changing carts to perform fully automated mold-changing functions.

In injection molding production lines, companies who continue to improve the production technology, and control the unnecessary waste at the lowest level, will continue to move towards fully automatic production and are qualified to talk about the constant operation.

We hope these tips on efficient quick mold change installation for plastic injection molding will give a hint to you. As long as our enterprises or manufacturers get an efficient quick mold change installation, their plastic injection molding production will continue to meet the fierce market competition.

Contact HVR now to electrify your workflow. You can click here to know more about QMC: https://www.magneticplaten.com/app-list.html

Tips for efficient, quick mold change in the plastic injection machine