Understand How Magnetic Platen Saves Time

Injection molding is a widely used manufacturing process in which molten material is injected into a mold cavity, resulting in the production of various products. The efficiency and productivity of…

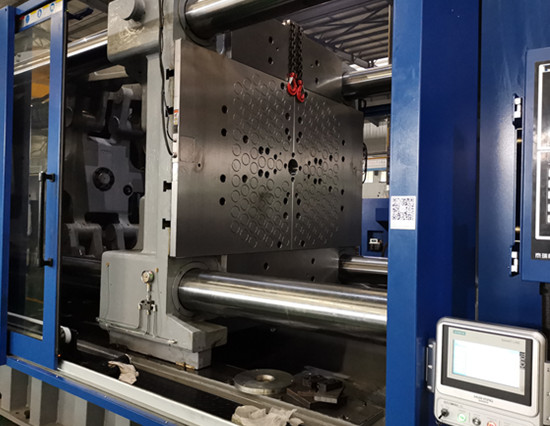

Types of Mold Clamping for Injection Molding Machine

When it comes to injection molding machines, the clamping mechanism plays a crucial role in securely holding the mold during the injection process. Three commonly used clamping methods are hydraulic…

Magnetic Templates for Injection Mould Clamping

Injection mould clamping plays a crucial role in the manufacturing industry, ensuring precise and secure positioning of moulds during the production process. To enhance efficiency and accuracy in this operation,…

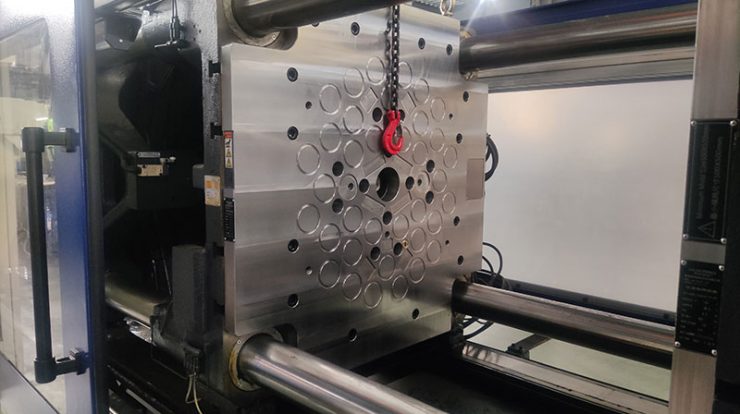

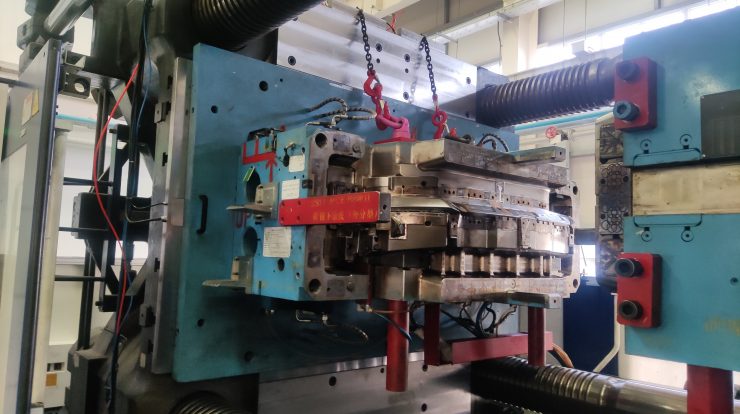

How to Reduce Mould Change Time with Magnetic Plates

Efficient mold changeovers are critical in industries. How to reduce mould change time with magnetic mold change systems?

Proper Maintenance Tips for Magnetic Templates in HQMC

Magnetic templates play a crucial role in quick mold change systems, ensuring efficient and precise mold positioning. To maximize their lifespan and performance, proper maintenance is essential. In this blog, we will provide valuable tips on how to properly maintain magnetic templates in quick mold change systems.

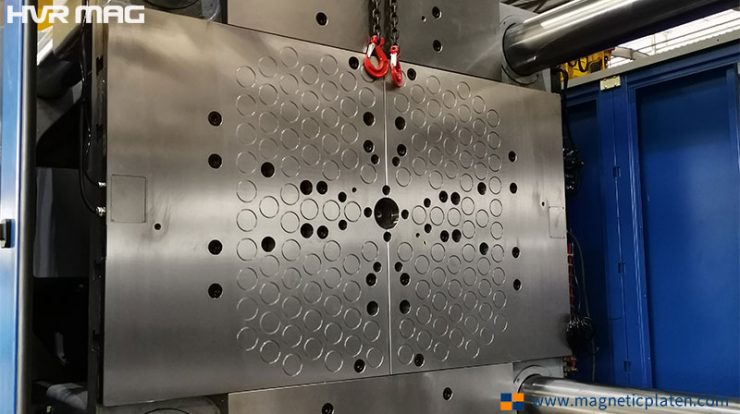

Can Magnetic Mold Clamping System Reduce Mold Change Time?

Magnetic mold clamping system can reducing the mold change cycle time to increase the production capacity of the plastic injection machine.

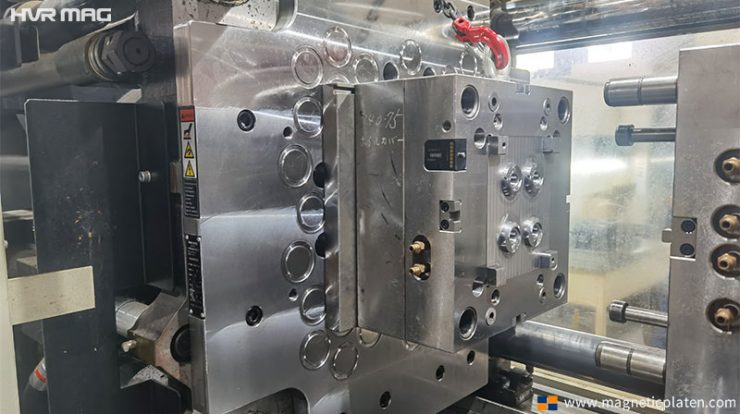

Magnetic Platens or Hydraulic Clamps – Quick Mold Change for 3300T IMM?

There are different types of quick mold change systems for plastic injection molding machines, among which hydraulic clamps and magnetic platens are the most commonly used. Do they perform the…

Magnetic Platens – HVR MAG’s Advantages over Staubli/Tecnomagnete/EAS

Through comparing magnetic platens manufactured by different suppliers – Staubli, Tecnomagnete, EAS and HVR MAG, to learn about HVR MAG’S advantages on injection molding mold change.