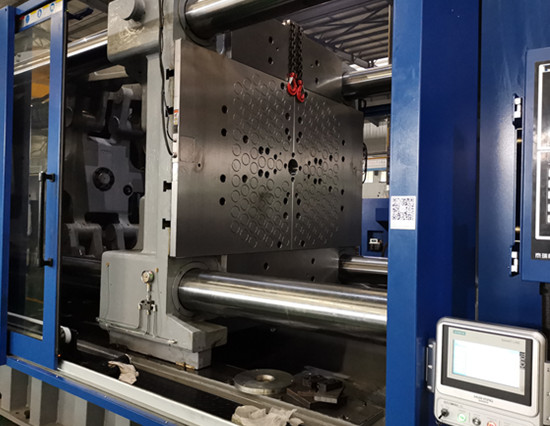

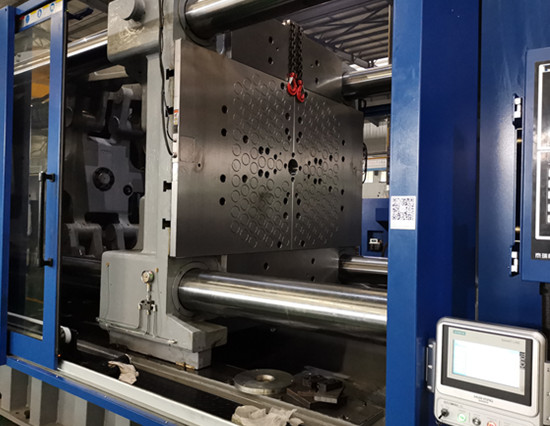

With magnetic platens being used as mold clamps for quick mold change in injection molding, manufacturers of magnetic mold clamping plates are in an increasingly fierce competition of embracing the challenge of quick changeover of molds, to optimize their injection molding productivity and overall efficiency. Here, we’ll make a simple comparison of magnetic mold clamps from branded suppliers.

Compared with magnetic platens manufacturer – Staubli:

HVR MAG‘s magnetic platens have all the advantages and safety features of Staubli’s. More than that, our magnetic platens possess extra competitive edge:

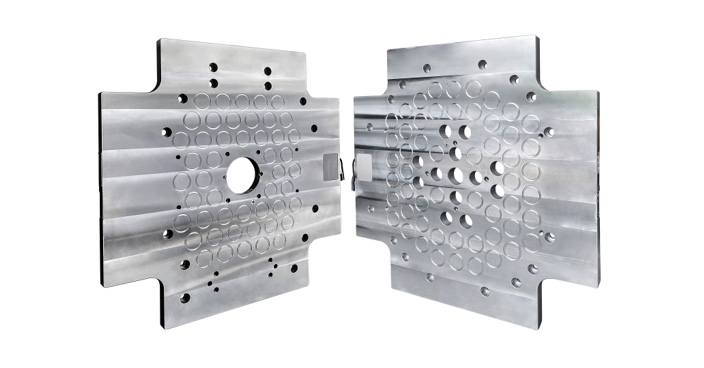

- More smooth magnetic flux (the permanent magnetic part circuit is better), higher attraction force generated by a single magnetic pole

- Better sealing of surface → longer service life → lower error rate

- More safety protection measure – distance detection switch, misoperation detection, two types of magnetic flux detection

- Also equipped with safety chains

Compared with magnetic mold clamps manufacturer – EAS:

- HVR MAG’s full range of magnetic platens are ALL equipped with temperature sensors & magnetic flux sensors (unique patented digital magnetic flux detection technology, with higher detection accuracy, no drift, and no need for regular calibration), while EAS clamping plates are configured ONLY for some models;

- Our distance detection switch – proximity sensor, can withstand high temperature and collision;

- Touch screen interfaces are equipped with force measurement and safety factor calculation;

- Sealings of magnetic poles: metallic seal

- Also equipped with error detection sensors, providing more and higher safety protections;

- With safety chains

Compared with magnetic clamping plates manufacturer – Tecnomagnete, HVR MAG’s advantages are as follows:

- More smooth magnetic flux → higher attraction force generated by a single magnetic pole

- For magnetic plates of the same tonnage, ours are designed with stronger magnetic force and higher plate intensity

- Our plates can be repaired on-site, while Tecnomagnete’s can not

- With better proximity sensor. Technomagnete’s is too easily to be damaged under high temperature conditions, which is a throne in customer’s side.

Just to clarify, this comparison is not aiming to prove which magnetic platens manufacturer is the best. Each magnetic platen supplier has its own strength and professionalism. Different molders would probably go for different types of magnetic plates due to various considerations.

Learn more about mold change for plastic injection molding machine, feel free to leave us a comment or welcome to visit our website:www.magneticplaten.com