Quick mold change system supplier and manufacturer, HVR MAG, explains some of the most frequent asked questions (FAQ ) about magnetic platens in injection molding. Hope this will be helpful to you.

If the power suddenly goes off, will the mold fall off?

No, the mold won’t fall off. Due to the electro-permanent magnetic clamping technology of HVR MAG’s quick mold change system utilized, once been magnetized, the magnetic clamping force of magnetic platens can remain permanently, unless otherwise demagnetized. Therefore, the mold will not fall off in a power failure.

Is Magnetic Field Radiation Harmful to the Health of Human?

No, harmless. Magnetic clamping plates of HVR MAG’s quick mold change system, once been magnetized, can form a closed magnetic field on the surface of themselves. The effective range of distance for magnetic line is 20mm within the plate. Beyond that range, the magnetic field strength becomes as thin as to that in the air. Therefore, it should be noted that people with pacemakers, or any item like bank cards, watches, mobile phones and other similar articles, should not enter into the range of 20mm within the surface of platens.

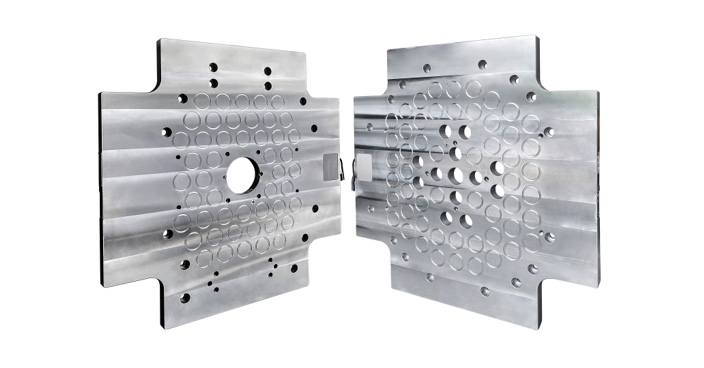

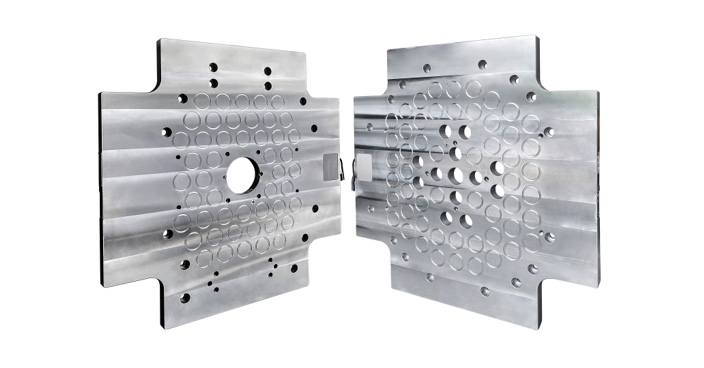

Are the clamping plates water-tight, oil-proof, corrosion resistant?

Absolutely. HVR MAG’s magnetic clamping plates for quick mold change system, are designed with multi-layer structure which is waterproof, oil-proof and corrosion resistant.

Can the platen withstand high temperature?

The allowable operating temperature ranges for magnetic platen are as follows:

T1: 0~120℃; T2: 0~150℃; T3: 0~180℃

When at temperature higher than 180℃, we do not suggest use.

Will the platens affect the functioning of robotic arms or injection molding machine?

No, no interference. They only use electricity in a moment for mold change, at the rest of the time, completely out of connection to electric power; moreover, the effective range of distance for magnetic filed is only 20mm within the plate, any place outside that range has barely no magnetic filed. Thus, they will not affect the functioning of robotic arms or injection molding machine.

What to do if the back base of the mold is uneven?

The back base of the mold must be in full contact with magnetic platens so that it can be successfully clamped. To that end, certain adjustments must be made: remove the bulgy part, such as the edge of a dent; tighten the screws and guide pins on the back side; remove the thick dirts on the back side.

Other questions about quick mold change in injection molding, will be answered and listed by quick mold change system supplier’s coming post: https://www.magneticplaten.com/blog/faq-about-quick-mold-change/