Injection Molding Clamping Unit – Definition/Types/Comparison

What Is Injection Molding Clamping Unit? A clamping unit for an IMM is used to keep the mold shut against the forces developed when injection pressure pushes plastic into the…

FAQ About Quick Mold Change System – PART Ⅰ

HVR MAG would like to answer some frequently asked questions about Magnetic Quick Mold Change for Injection Molding Machine.

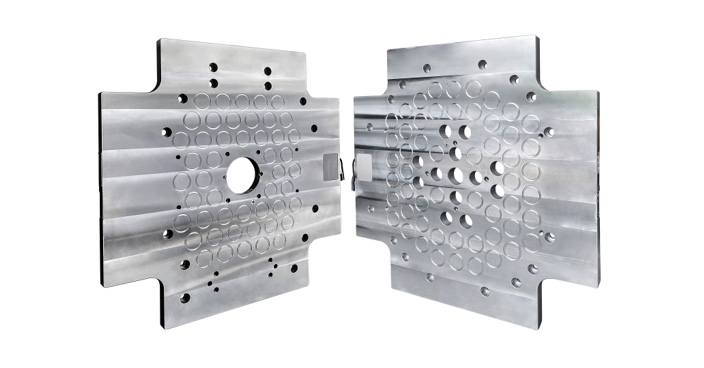

Factors to Consider When Designing the Mold Clamping Force of Magnetic Platens

Magnetic mold clamping system supplier, HVR MAG explains the design factors of the mold clamping force of magnetic platens. Before getting straight to the point, we need to learn about the mold…

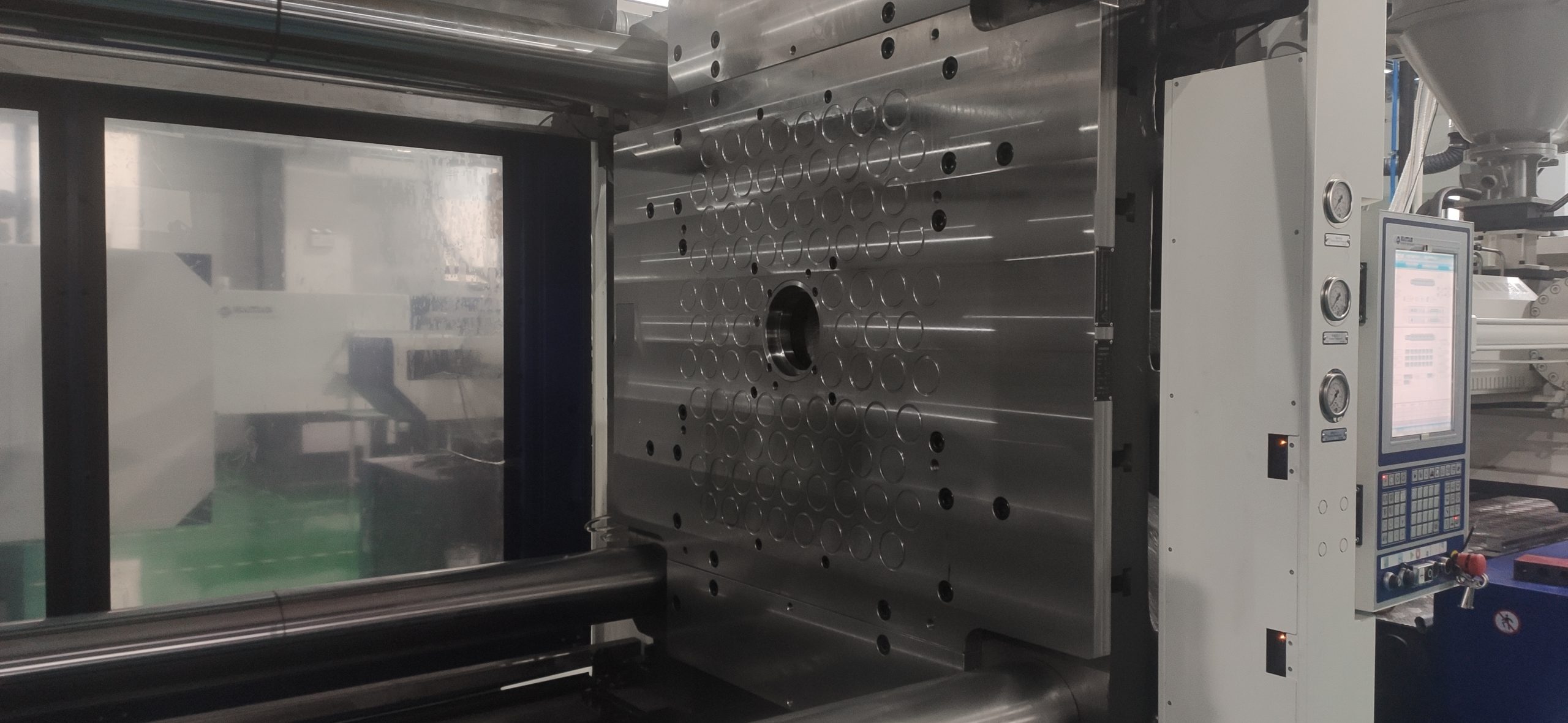

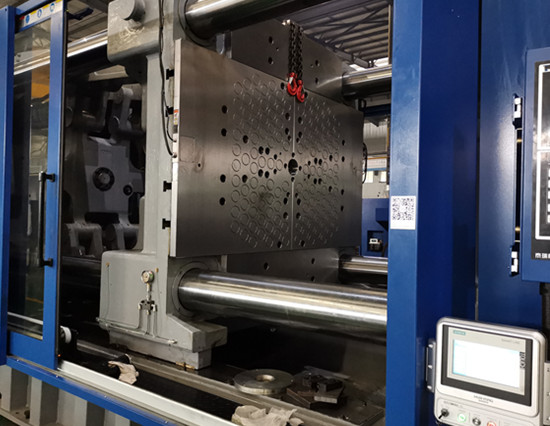

46mm Magnetic Platens on HAITIAN 600/1000/1200 Ton Injection Molding Machines

It is widely understood that reduction of mold changing time can lead to an overall improvement in productivity in injection molding. As a professional manufacturer and provider of quick mold…

Magnetic Platens – HVR MAG’s Advantages over Staubli/Tecnomagnete/EAS

Through comparing magnetic platens manufactured by different suppliers – Staubli, Tecnomagnete, EAS and HVR MAG, to learn about HVR MAG’S advantages on injection molding mold change.

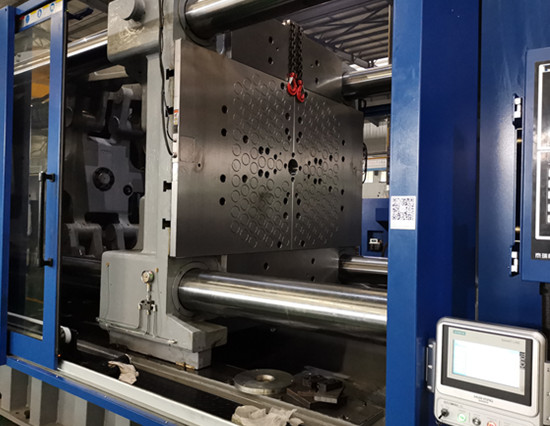

An Installation Guide to Quick Mold Change System

A guide to the things that should be noticed and prepared before starting the installation of HVR MAG’s quick mold change system, could be beneficial to your injection molding machine.

Staubli Magnetic Mold Clamping System VS HVR MAG Magnetic Mold Clamping System

Comparison of magnetic mold clamping system for injection molding from Staubli and HVR MAG, the latter provides a more versatile range of mold clamp applications.

Comparison of Mold Clamping Systems for Injection Molding – Mechanical, Hydraulic, Magnetic

Understanding the basic features of mold clamping systems for injection molding – mechanical, hydraulic, magnetic, can help you choose the proper quick mold clamping system that best suits your machine to gain maximized productivity | HVR MAG

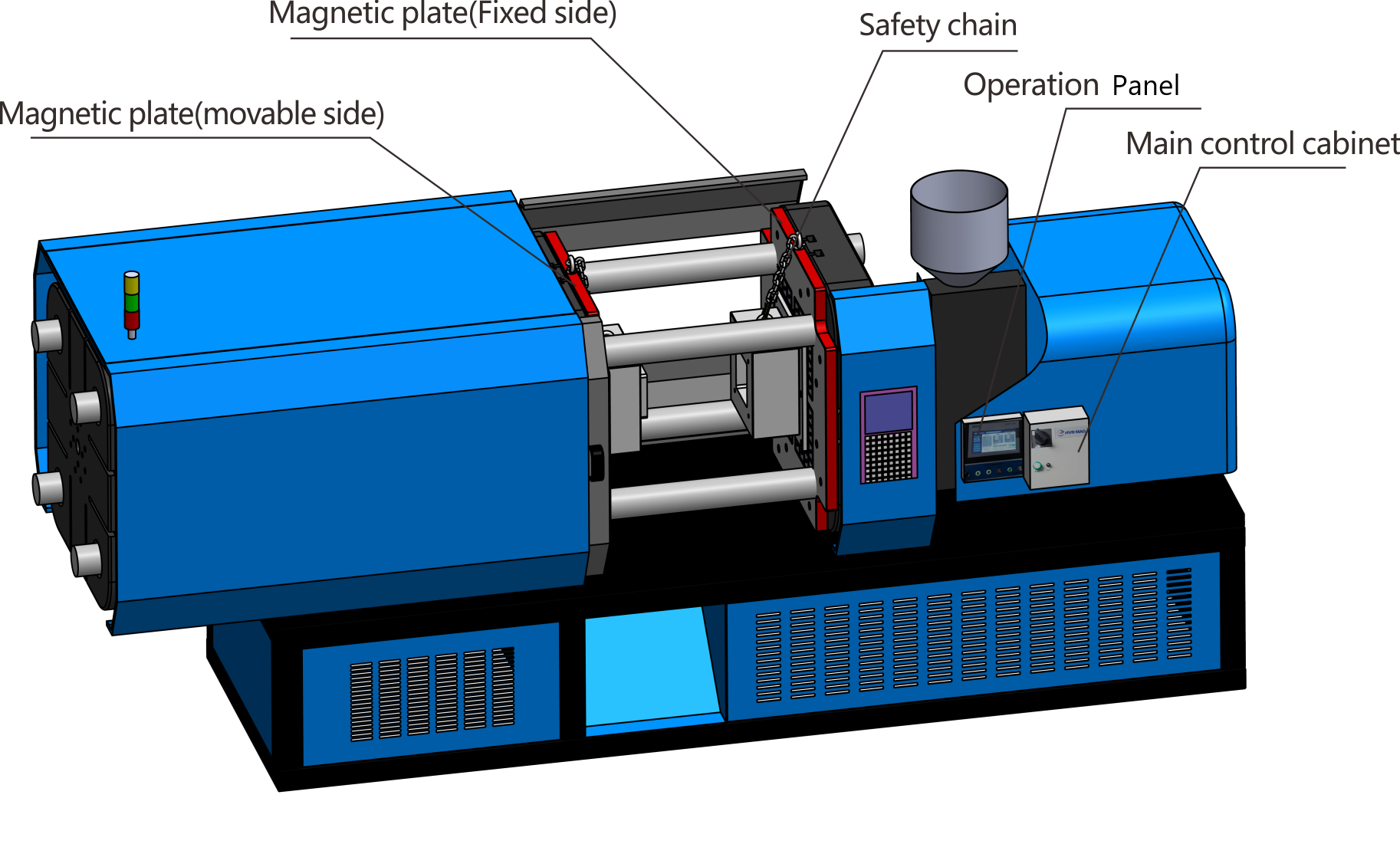

8 Safety Attributes of HVR MAG Quick Mold Change System

Utilizing magnetic clamping technology in providing magnetic mold clamping solutions – quick mold change system, for plastic injection molding machine, HVR MAG helps make the mold changeover more efficient and cost-effective.