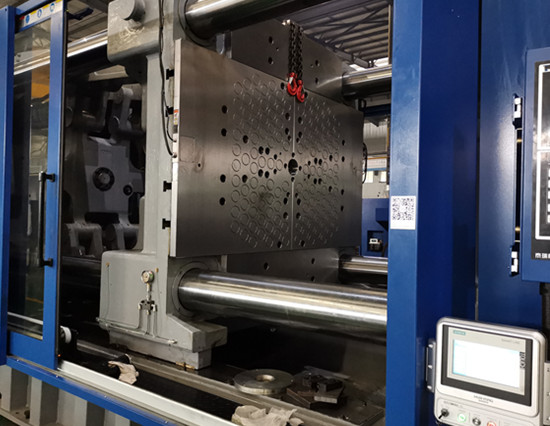

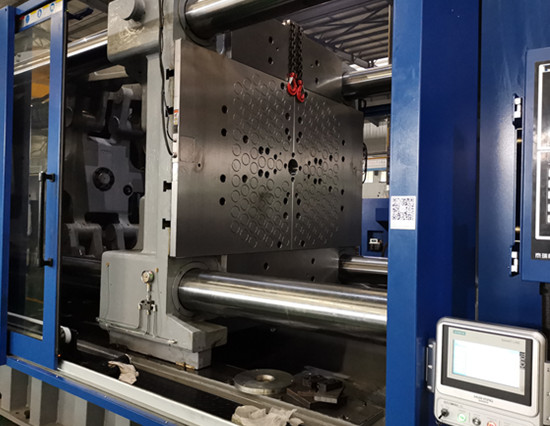

If your company’s in plastics industry, you’ve probably heard about Staubli, a global mechatronics solution provider headquartered in Pfäffikon, Switzerland. They developed a magnetic mold clamping system called QMC122. Here, let’s go a little more deeper about this mold change solution for injection molding.

Staubli’s magnetic mold clamping system only provides clamping plate with a thickness of 52mm, whereas in HVR MAG, we supply thinner magnetic plates with a thickness range of 35mm, 46mm and 51mm. Moreover, HVR MAG designs and manufactures magnetic platens with higher maximum operating temperature to adapt to more complicated working environment. For further detailed technical parameters of our plates, please refer to the following chart:

| Magnetic Pole Size | Φ44 | Φ66 | □50×50 | □80×80 |

|---|---|---|---|---|

| Magnetic Force Per Pole (Kg) | 350 | 900 | 400 | 1000 |

| Template Thickness(mm) | 35 | 46 | 35 | 51 |

| Max. Operating Temperature(℃) | 120/150/180 | |||

| Standard Voltage | AC 220V/380V/415V/440V |

|||

| Frequency | 50/60HZ |

|||

Mold Clamping Force of Injection Molding Machine |

500KN – 40000KN |

|||

Other than the above mentioned, HVR MAG electro-permanent magnetic plates for injection mold change, are designed with waterproof, anti-oil, corrosion-resistant steel surface, featuring mold dislocation detection, magnetic flux detection on both fixed and movable plates, and temperature sensor in fixed plate. Magnetic plate size/shape can be tailor-made to best fit your mold change process.

In addition, HVR MAG can equip either a standard interactive control panel, or an upgraded touch screen control panel, for your magnetic mold clamping system, upon request. Through this, the molder can get a direct view of the clamping force in real time controlled accurately by the system. Contact us if you want to optimize your mold change efficiency and overall productivity.