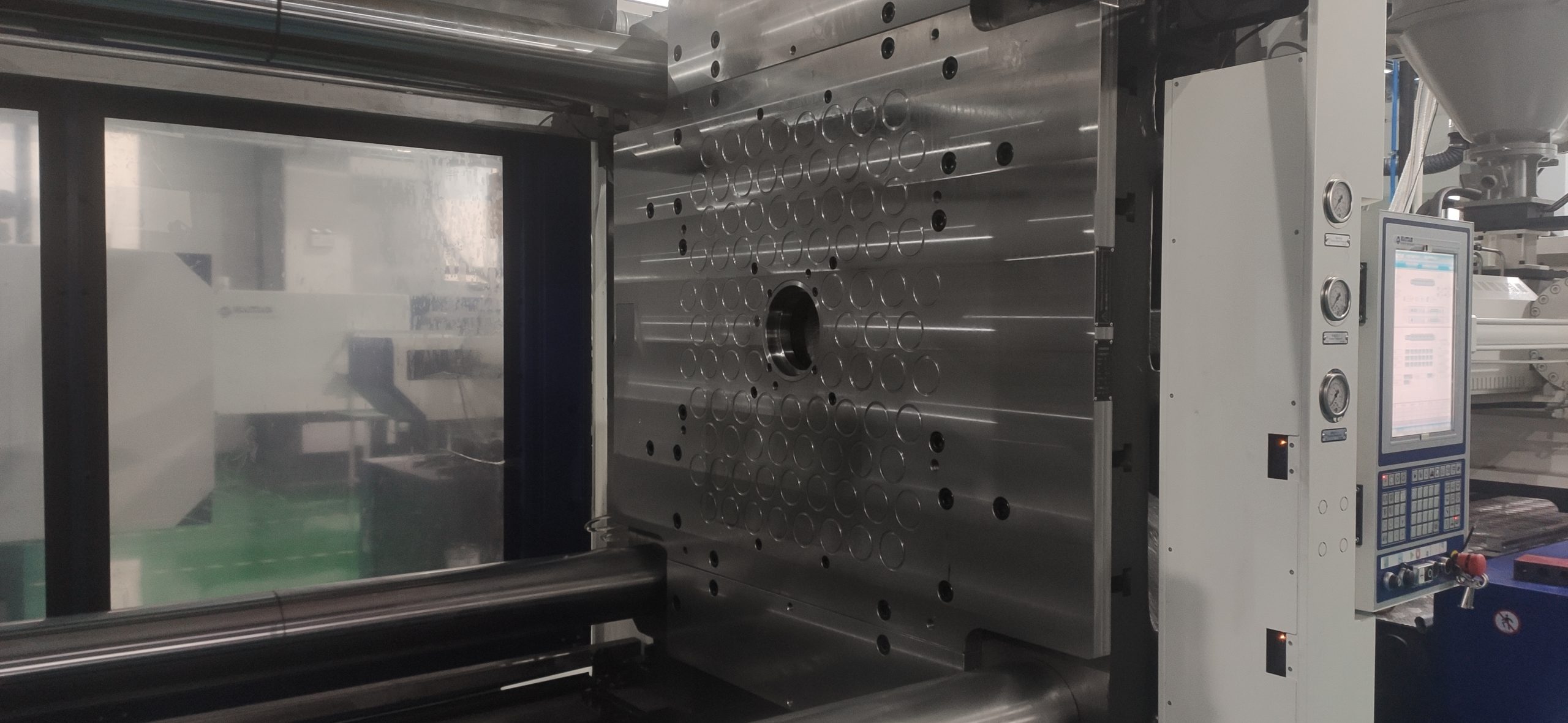

Magnetic mold clamping system supplier, HVR MAG explains the design factors of the mold clamping force of magnetic platens.

Before getting straight to the point, we need to learn about the mold clamping force of magnetic plates. The magnetic clamping plate uses the friction generated by the clamping force on the back side of the mold to withstand the mold’s own gravity, so as to keep the mold from falling off.

There are several things to consider when designing the mold clamping force.

Weight of The Mold

On the basis of the friction coefficient being 0.2-0.3, under normal circumstances, the clamping force of magnetic plates should be at least 5 times the weight of the mold itself to be considered safe enough.

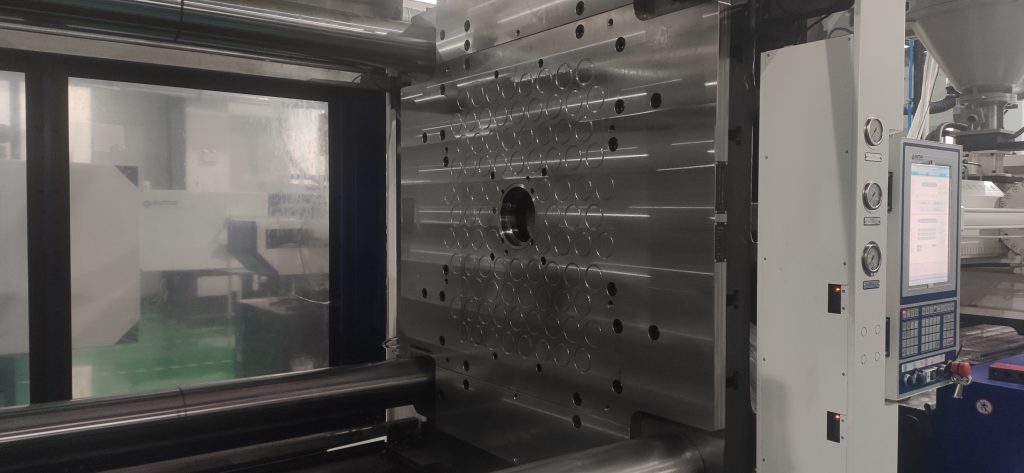

The Maximum Opening Force of the Injection Molding Machine

The higher the clamping force, the safer it is? Within a certain limit, yes it is. So how much should the upper limit be set? Well, it should NOT Exceed the maximum mold opening force of the injection molding machine.

Considering the possible demagnetization failure of the magnetic template, the mold is clamped on the platen and cannot be removed, with the connecting bolt holes of the magnetic template and the injection molding machine mold base been covered by the back side of the mold. On that condition, there is no way to disassemble the clamping plate. The only way to achieve that is to fix the left and right halves of the mold, open the mold forcefully through the injection molding machine to pull the mold from the magnetic template, then remove the unilateral magnetic plate, and fix the unilateral with a mechanical fixture. After the mold is opened, the mold is opened again, and the other side of the mold is pulled down.

It can be concluded that the mold clamping force of the platen shall not be higher than the maximum opening force of the injection molding machine. HVR MAG’s mold clamping plates are designed with multi-unit structure. When a certain part of the clamping plate goes wrong, the other part that does not, can be demagnetized.

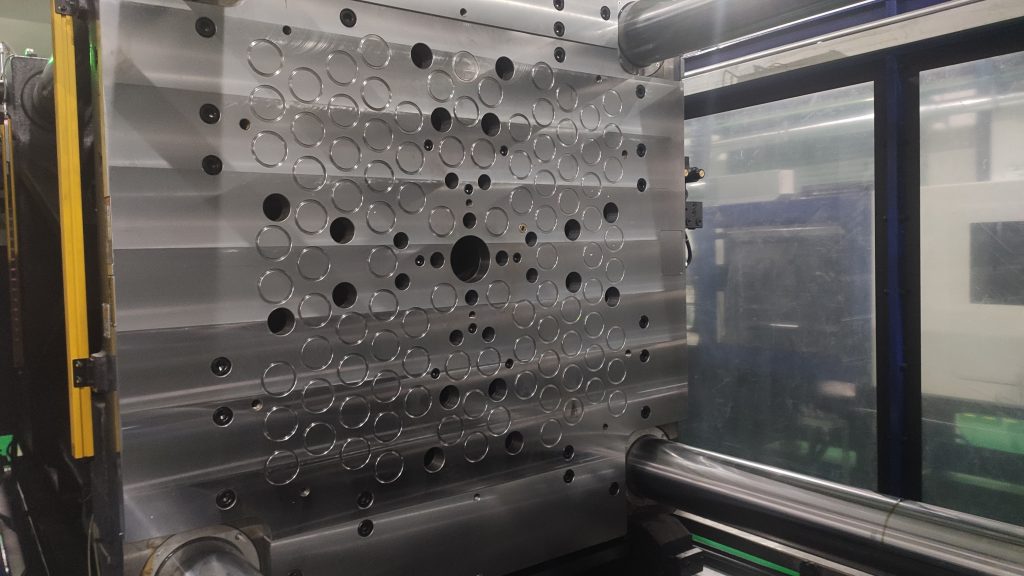

The Clamping Force of Movable Platen Should Be Higher Than That of Fixed Mold

The weight of the movable plate is usually heavier than the weight of the fixed one. And because of that, according to factor one, the movable plate requires higher clamping force than the movable platen does.

When starting to open the mold, once the mold been pulled off the fixed clamping plate, the proximity sensor inside the platen and the magnetic flux detection sensor can immediately notice that. And an emergency stop will be put to the mold opening procedure.

At the fixed side of the mold base of the injection molding machine, there usually is a 2cm thick positioning ring. When an emergency stop occurs, the positioning ring can ensure that the mold does not fall off.

Just to clarify, the above mentioned factors for consideration when designing the mold clamping force of magnetic platens, are personal perspectives, based on our years of research experience on magnetic mold clamping system. Or, if you have a different opinion, please feel free to leave a comment below.