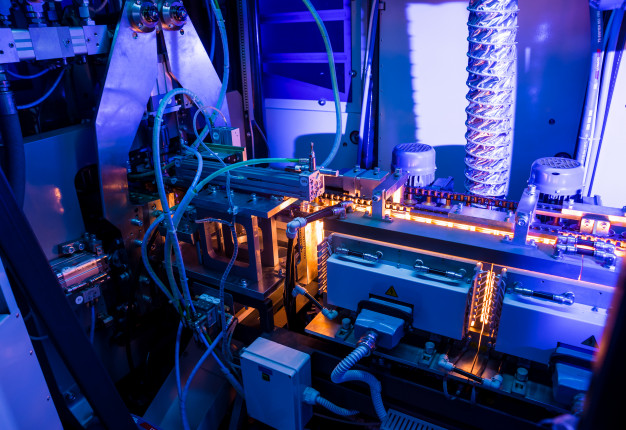

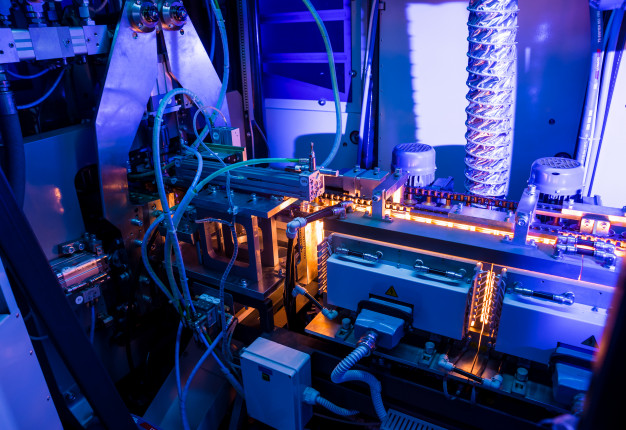

For moulders or people who’re engaged in plastics industry, injection moulding (molding) is no stranger to them. Yeah, it is a manufacturing process for producing parts by injecting molten material into a mould(mold). Here comes our topic today, how many types of injection moulding process are there?

Or we can put it in a different way, what are the different types of injection moulding process?

Most types of injection moulding processes can be classified into, but not limited to:

Metal injection moulding – a metalworking process in which finely-powdered metal is mixed with binder material to create a “feedstock” that is then shaped and solidified using injection molding. The molding process allows high volume, complex parts to be shaped in a single step.

Die casting – a metal casting process that is characterized by forcing molten metal under high pressure into a mould cavity. The mould cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mould during the process.

Injection moulding of liquid silicone rubber – This process molds silicone rubber into a broad array of parts and products. While the traditional reaction injection molding (RIM) process focuses on a pressurized impingement mixing process, Liquid Injection Molding is comprised of a mechanical mixing method that blends a two-component compound together in a mold

Thin-wall injection moulding – a specialized form of conventional injection molding that focuses on mass-producing plastic parts that are thin and light so that material cost savings can be made and cycle times can be as short as possible. Shorter cycle times means higher productivity and lower costs per part.

Gas-assisted injection moulding – a molding process where an inert gas is introduced at pressure, pushing the plastic melts into the mold extremities at the end of the polymer injection phase.

Reaction injection moulding – It is a low pressure, low temperature process used to mold many types of plastic parts. This process is typically used for the medical, industrial and automotive industries.

Micro injection moulding – It’s a molding process for the manufacture of plastics components for shot weights of 1 to 0.1 g with tolerances in the range of 10 to 100 microns. This molding process allows to manufacture complicated small geometries with maximum possible accuracy and precision.

Cube mold technology – a molding process for the manufacture of plastics components. This molding process allows to manufacture circular parts. This technology was introduced by Foboha and Arburg.

After an explanation of each type of injection moulding process, do you have a better understanding about the plastics industry now? Stay connected with www.magneticplaten.com/blog for further updates on injection moulding.

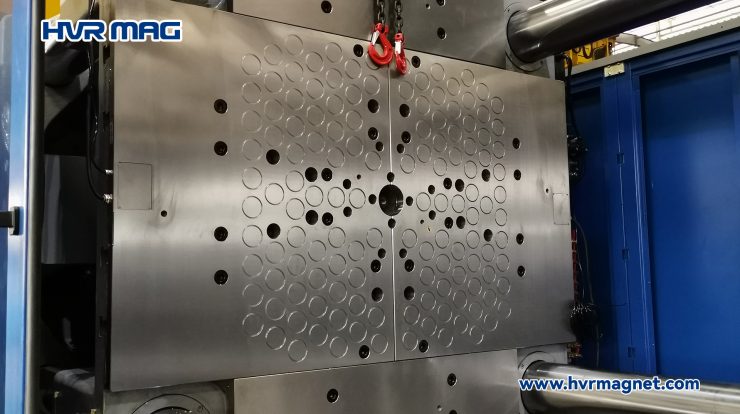

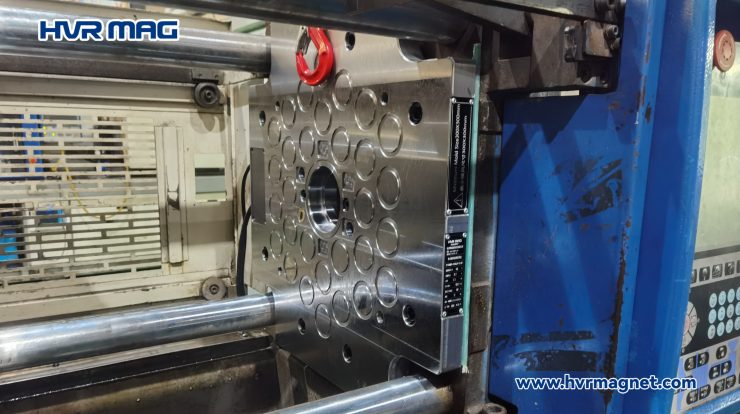

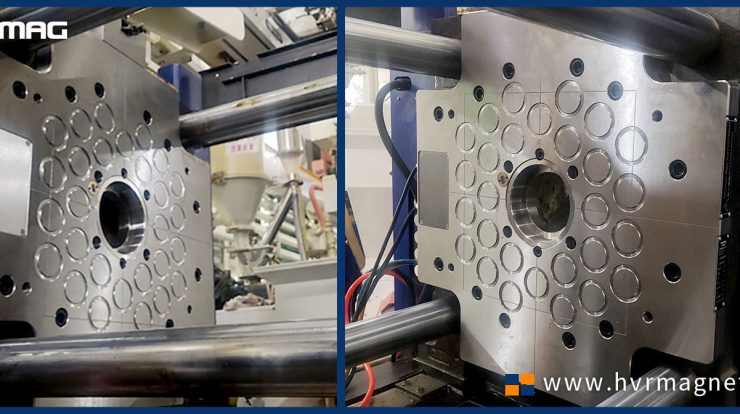

Learn more about mold change for plastic injection molding machine, feel free to leave us a comment or welcome to visit our website:www.magneticplaten.com