What’s plastic injection mold, why is it so expensive and what’s injection mold making process – get answers for these questions.

Look at the staff around us, it’s not hard to find that most of them are made of plastics. We know that plastic products of varying forms are manufactured by injection molding machine through a plastic injection mold. But has anyone ever wondered that how are injection molds made? Are they expensive? How are injection molds made?

What is a plastic injection mold?

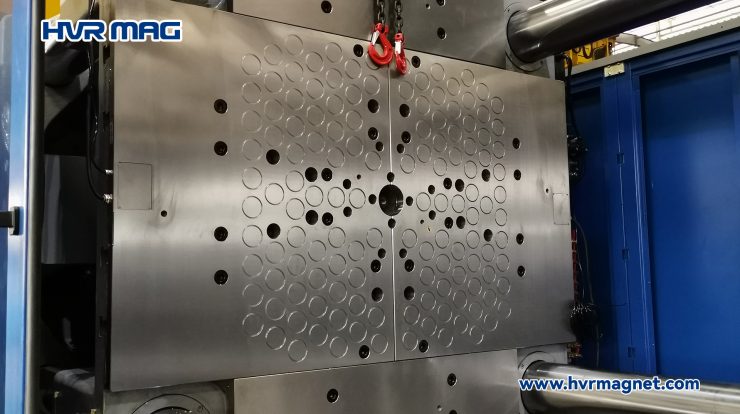

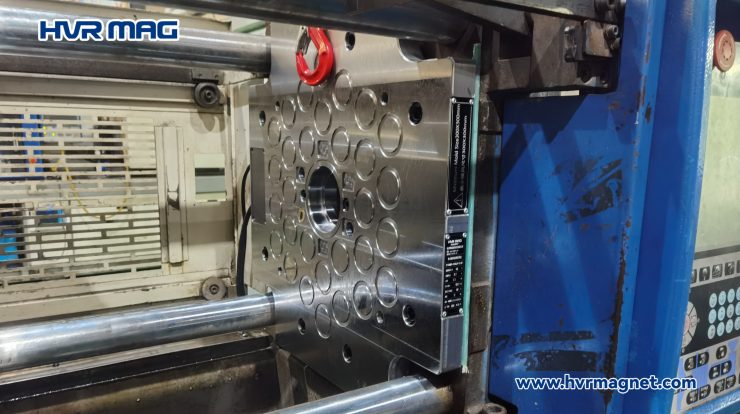

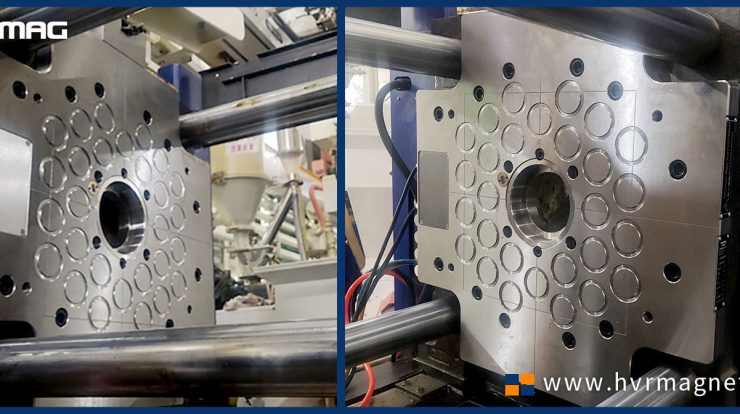

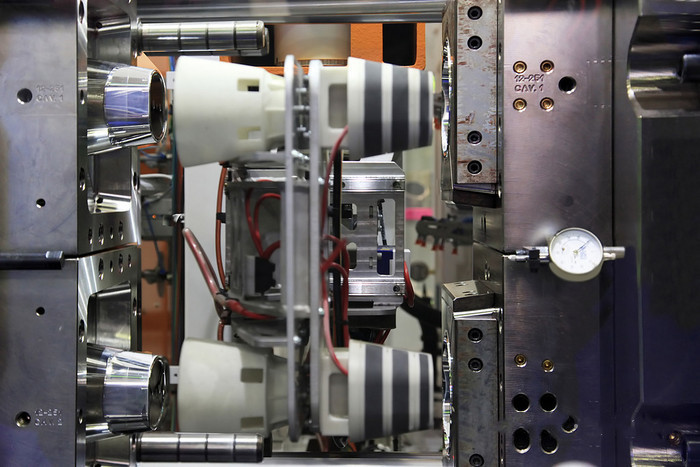

A plastic injection mold, usually designed as a hollow metal block with cavities, is used to give shape to molten plastics via the process of injection. There are multiple holes made inside the mold to realize temperature control by way of oil, water or heaters.

The sprue in the mold allows the melted plastic to flow in, which will then fill the cavities through the runners and gates. After being cooled, the mold will be opened, and the molded parts will be further ejected by a push on the ejector plate by the ejector rod of the injection molding machine

Why Is A Plastic Injection Mold So Expensive?

An injection mold is easily the most expensive part of the project, and can dramatically increase costs for small part runs. The determining factors in the cost of an mold are a combination of the part size, complexity, material, and anticipated quantities.

Injection molds are subject to thousands of pounds of pressure every cycle. As a result, the molds must be made from very strong materials that can withstand repeated use without deforming. The most common choice for injection molds is steel, with the grade of steel determined by the number of parts to be produced and the material to be injected into the mold. (For example, a fiberglass filled material causes a lot of wear when injected, so the mold would need to be made from a higher grade of steel.)

Another factor that determines injection mold costs is the complexity of the part to be produced. The more complex your part, the more complex and costly the mold. And once made, molds are difficult and many times impossible to modify, removing your ability to modify the design.

Normally, a small, single cavity plastic injection mold usually costs between $1,000 and $5,000. Very large or complex molds may cost as much as $80,000 or more. On average, a typical mold costs $12,000.

How to Make A Plastic Injection Mold?

Generally speaking, the injection mold making process consists of the following parameters:

Mould & Plastic Material Analysis → Mould Style & Costing Selection → Mould Cavity Splits & Shrinkage → Choosing Cutting Method → Mould Design → CNC Programming Setting Up The Job → Polishing & Fitting → Debugging the Mold

Factories make product parts by melting materials such as metal rubber or plastic, then pouring or injecting them into molds to make a plastic part for a product. To that end, manufacturers have to first approach a plastic injection mold maker to design and produce a plastic injection mold. Understanding the basic know-how about plastic injection molds can be beneficial to their plastics business.

Learn more about mold change for plastic injection molding machine, feel free to leave us a comment or welcome to visit our website:www.magneticplaten.com