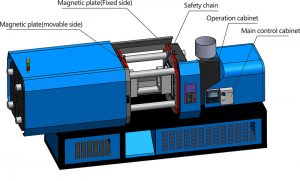

The quick die change system of HVR is different from mechanical and hydraulic type. Our quick die change system uses magnetic suction to clamp the injection mould and consists of two magnetic plates, a controller and an operation panel. The advantages of the magnetic clamping system are as follows.

Convenient:

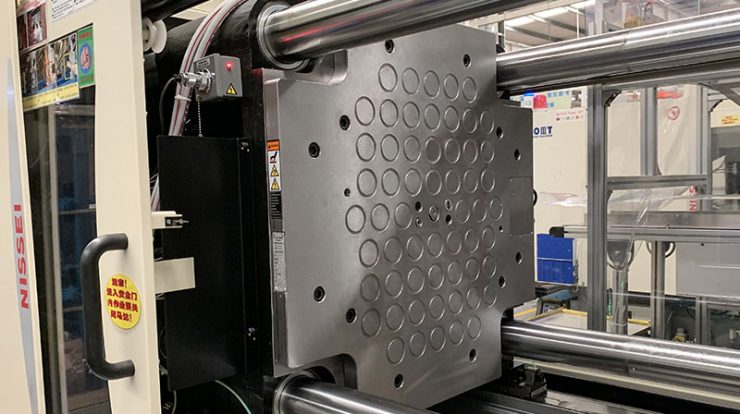

The magnetic platen of the HVR quick die change system is a very smooth, all-metal flat plate. Whether the mould is lifted into the injection moulding machine from the top or pushed into the machine from the side without any obstruction. The magnetic platen is mounted directly onto the back plate of the injection moulding machine without any modifications to the machine or mould.

Energy saving:

The magnetic template is made of electro-permanent magnets(EPM). The principle of EPM is different from electromagnet. Electromagnets are made from copper coils. The coil produces a magnetic field only when it is energized. The magnetic field disappears when the power is cut off. It consuming a lot of electricity during operation. Like ordinary permanent magnets, EPM are made of magnetic material. When the magnetic field is applied to the workpiece, the magnetic force is permanent. The difference between EPM and permanent magnets is that EPM use an electric current to switch between magnetised and demagnetised states. A single energisation takes only 0.2-2 seconds.

Safe:

EPM are internally composed of both NdFeB and Alnico magnets. This is the most powerful magnet available. Hence, there is no need to worry about the mould falling off due to insufficient magnetism. At the same time, HVR’s quick die change system has a number of safety features. For example, the magnetic template has a temperature detector, a distance detector and a misalignment detector. The data from these detectors is recorded and displayed on the control panel. You can monitor the status of the mould and the machine at all times. This increasing safety during production.

Uniform force:

With other clamping methods, forces are applied to the mould at only a few points and the mould tends to loosen. With magnetic clamping, an even and powerful magnetic force is applied to the entire back of the mould. This ensures that the moulds open and close without slight deflection or gaps, preventing wear and tear. The quality of the product is also more consistent.

Smart:

As already mentioned HVR’s magnetic templates come with temperature sensing, distance sensing and misalignment detection. There is also magnetic flux detection. Our quick die change system automatically detects if the magnetic force has reached a set value and alerts you if the force is insufficient or decreasing. Such intelligent tools will give your company greater efficiency, more consistent product quality and a better corporate image.

If you need more information about HVR MAG and quick die change system, please contact us at: export@hvrmagnet.com