Will Clamping Method Affect the Quality of Product?

Plastic injection molding is a highly versatile process to produce complex shapes and parts with a high degree of accuracy and consistency. Injection molding machines have varies of size and…

Proper Maintenance Tips for Magnetic Templates in HQMC

Magnetic templates play a crucial role in quick mold change systems, ensuring efficient and precise mold positioning. To maximize their lifespan and performance, proper maintenance is essential. In this blog, we will provide valuable tips on how to properly maintain magnetic templates in quick mold change systems.

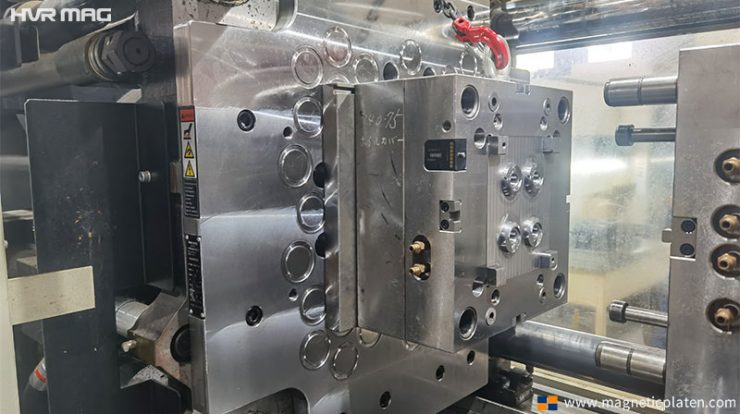

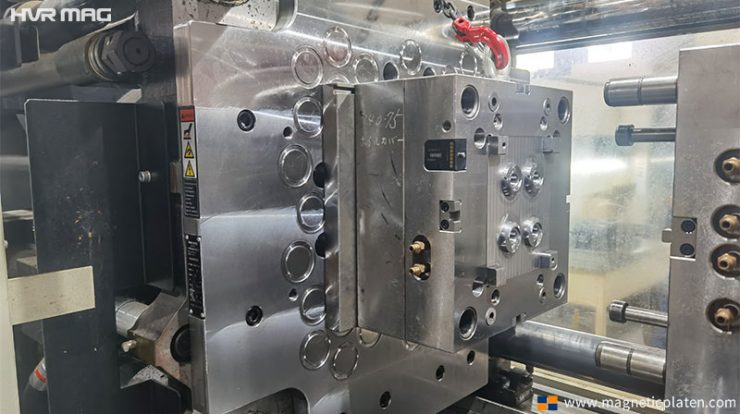

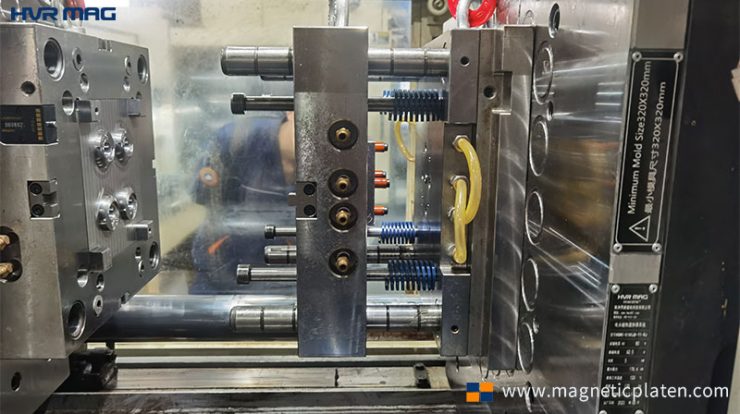

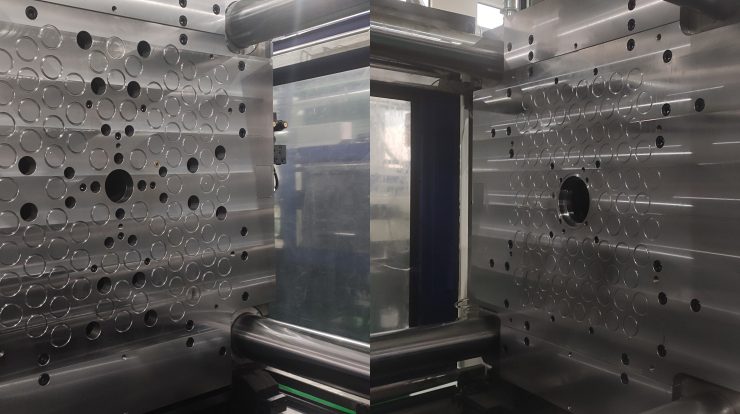

Magnetic Mold Clamping Devices on Injection Molding Machine

Magnetic mold clamping devices offer strong holding force, quick mold changes and improved part quality for injection molding machines.

Best Injection Mold Clamps: Magnetic Mold Clamping System

In order to achieve consistent and high-quality results, it is essential to have a reliable and efficient injection mold clamps. The magnetic mold clamping system is widely regarded as the best option of injection mold clamps.

Magnetic Clamping Device Design Principle

The magnetic clamping device can reduce mould change time and increase productivity. Here I will introduce you to the design principle of it.

Magnetic Mold Clamps for Injection Mold Manufacturing

As a mature and professional supplier of magnetic mold clamping systems to plastic injection molding and injection mold manufacturers all over the world, HVR MAG is sharing an application case of magnetic mold clamps for injection mold manufacturing here.

How Magnetic Quick Mold Change System has become a Mainstream Product for Injection Molding Machines?

How magnetic quick mold change system has become a mainstream product for injection molding machines? Quick mold change is the development direction of the worldwide injection molding industry. In recent years, the Chinese market has changed significantly and the technology has been upgraded rapidly. So it is impossible to win in the current market situation simply by relying on cheap labor and low-cost resources. At present, what customers pay most attention to is not the price factor, but the production efficiency and product performance. Enterprises need to upgrade their technology to achieve greater added value.

Manufacturing Process of Mold Clamp Magnetic Platen

An industrialisation process of mold clamp magnetic platen, guarantees reliability and performance of plastic injection molding process. Combining durability, safety, ease of use and efficiency, HVR MAG‘s magnet clamp is…