Often we ran into people posing questions like, how much does injection molding cost? Or is injection molding expensive? Asking such questions is equivalent of asking, to some degree, “how much does a car cost?” It’s hard to simply tell you how much, as the cost could vary within a wide range. The mainly determining factors in the cost of injection molding are a combination of the raw material, machine, mold, complexity and repair costs later down the road.

Raw Material Cost

What raw material the part should be made of? Maybe you say plastic. Yes, of course, plastic injection molder only do with plastic, but maybe you don’t know there are so many different types of plastic. The most common used are PP, PS, PC, Acrylic/PMMA PVC, PU, PET, HDPE, LDPE( and so on).

Injection Molding Machine Cost

IMM selection is another consideration in determining what plastic injection molds cost, that can go up or down, due to the following several specifications:

Clamping tonnage – the size of the machine indicated by how many tonnes of force is applied to clamp the moulds together during production. It could start from 10T (or even smaller) up to 4500T.

Motor & Drive – starting from a purely hydraulic system, to variable displacement pumps, to servo motors and to fully electric machines, there are many options to choose from. Its usually governed by the end use.

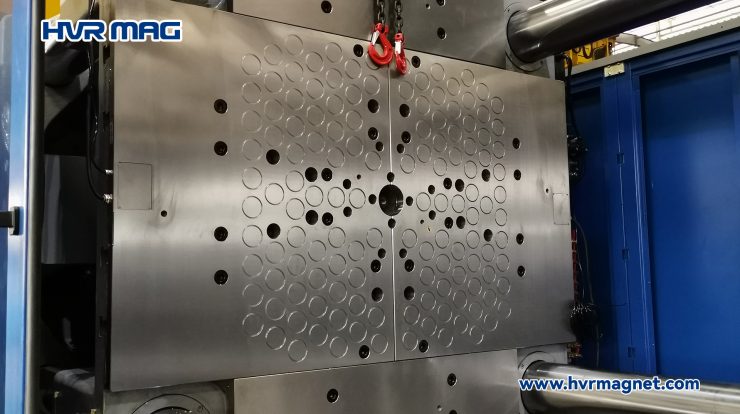

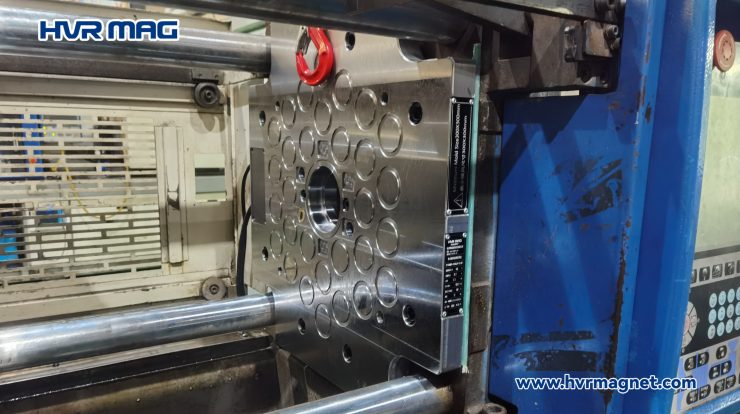

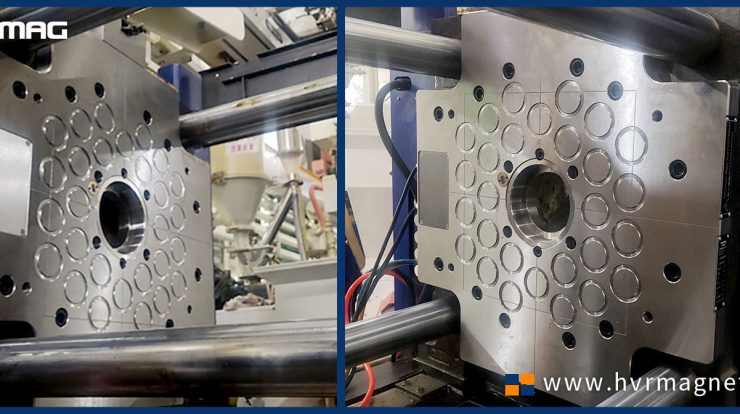

Technology & Brand – brands of IMM like Arburg, Engel, Nissei, Husky etc. introduce new features like better clamping systems, magnetic platen designs, barrel screws and injection systems with high end motors and drives that give repeatability up to 0.001g which is not possible in regular commercial grade machines. The cost attached to these though are also fairly large.

Mold Cost

Molds used in injection molding process are usually very expensive, sometimes more than that of the whole machine without mold. The cost of the mold depends on several factors, such as the size, design (number of cavities, cooling water canals), complexity of design, material of injection, and rheology of the material (viscosity and flow behavior). The bigger and more complex your part to be molded, the more the mold itself will cost you. Also, bigger molds can result in additional per piece costs due to the fact that more material will be needed to manufacture the part.It might be from few thousands to millions of dollars.

Though you don’t need to know every detail about the types of IMM, raw materials and molds available, it’s always a good idea to come prepared. Taking time to estimate the cost of injection molding is an important step to make before you proceed your molding business. Understanding the basic know-how that drives the majority of the cost of injection molding enables us to make relevant adjustments that will minimize your overall cost of injection molding.

Learn more about plastic injection molding, feel free to leave us a comment or welcome to visit our website:www.magneticplaten.com