In plastics, there are these 2 terms about injection molding machines that puzzle me, tonnage, clamping(clamp) force. Are these two refers to the same thing? And how to calculate the tonnage/clamping force of an injection molding machine?

To begin with, let’s talk about the terms.

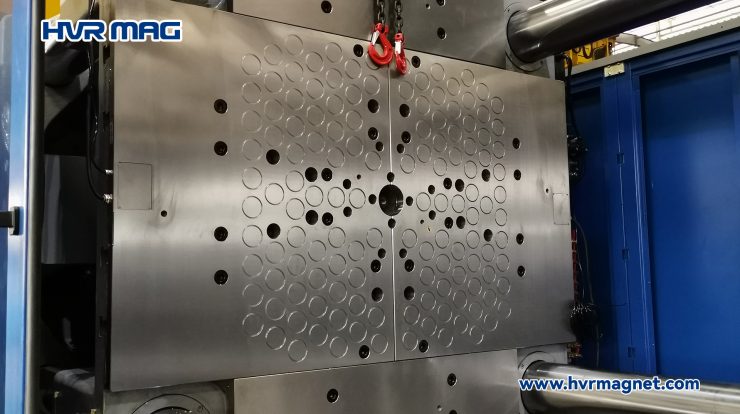

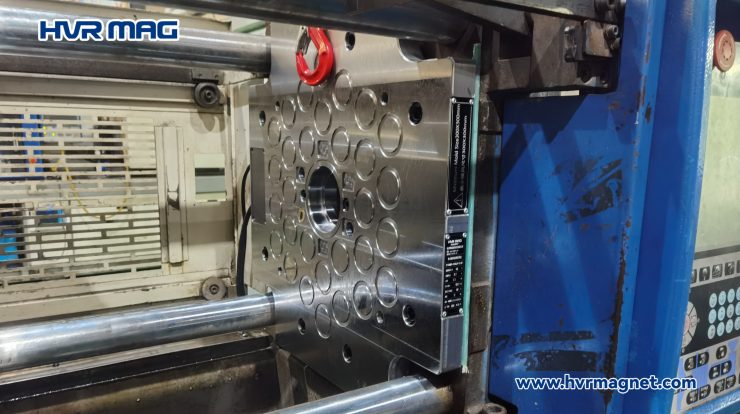

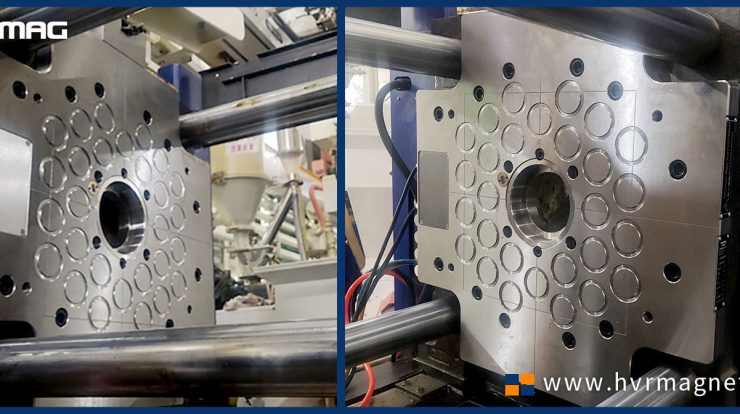

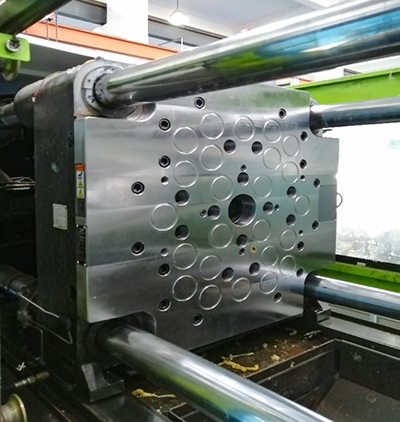

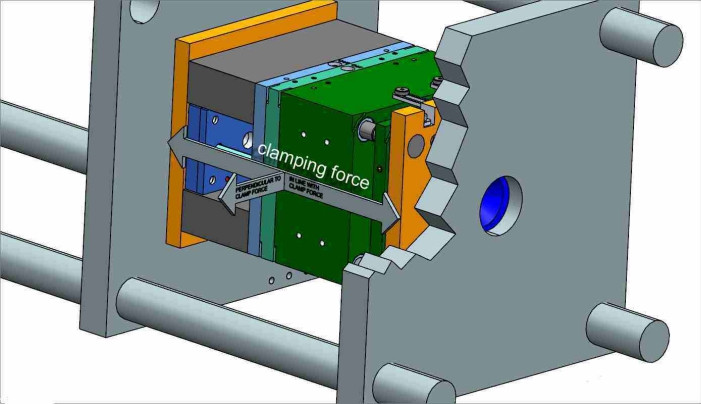

Tonnage is usually referred to the MAXIMUM clamping force of an injection moudling machine. It is the measure of force that’s required to keep the mold closed during the injection process. IMMs are classified or rated based on tonnage, or more specifically the clamping pressure or force. They can run in size from less than 5 tons of clamping pressure to over 4000. The higher the press ton rating, the larger the machine.

An IMM rated as 50 tons can deliver 50 tons of clamping pressure(force). The calculated tonnage can be used to select a capable machine that will prevent part defects, such as excessive flash. So how to calculate the clamping tonnage of IMM?

First, we need to calculate the two-dimensional projected area (surface area) of all parts and cold runners on the parting line of the mold. This simply means getting the square inch area of the cavity by multiplying the length by the width.

Clamping tonnage calculation formula: A = L x W or A=πr2. T = A x TF (tonnage factor).

Once you have calculated the surface area, then multiply it by a tonnage factor (recommended clamp force supplied by the material supplier in tons/in². Typically tonnage factors can range from 2 – 8 tons per square inch, depending on the material. For example, if we have a 5” X 5” part, the surface area is 25 square inches. Let’s further assume that our material calls for a 5X mold clamp factor. 25 times 5 equals 125, so based on our calculations up to this point, we will need to run these parts on an injection molding machine capable of at least 125 tons of clamping force.

Moreover, a safety factor of 10% should be added, so a final injection mold clamp force of 125 plus 1.1(tonnage factor) = 138 tons is needed. So at this point in our calculation, a 140-ton machine would be a good choice.

Till now, we’ve been through the definition of injection molding tonnage and how to calculate it. Selecting the right clamping tonnage for injection molding machine is vital –either too much or too little can cause quality issues, and problems for the parts or machine. For further details as to how the right tonnage affects your molding process, see our next post in next week.