What is an injection molding machine? How many types of IMM are there? – get answers for these quetions.

Beginners in plastic industry, would often pose questions like, “what is an injection molding machine? how many types of IMM are there? which is the best IMM?” Check this article out to get answers for these questions.

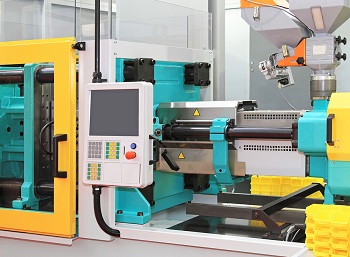

What Is An Injection Molding (Moulding) Machine?

IMM – Injection Moulding Machine, also known as an injection press, is a machine that is used for manufacturing plastic products by injecting plastic material into a mould. Material for the part is fed into a heated barrel, mixed and then put into a mould cavity where it eventually hardens taking the shape of the cavity. These types of machines consists of two parts – an injection unit and a clamping unit.

Horizontal & Vertical IMM

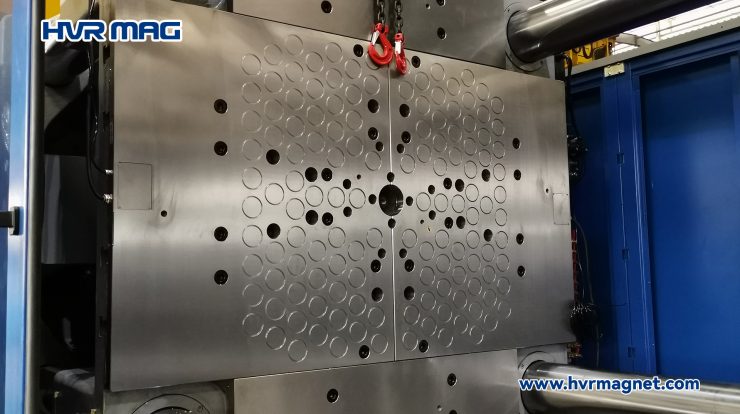

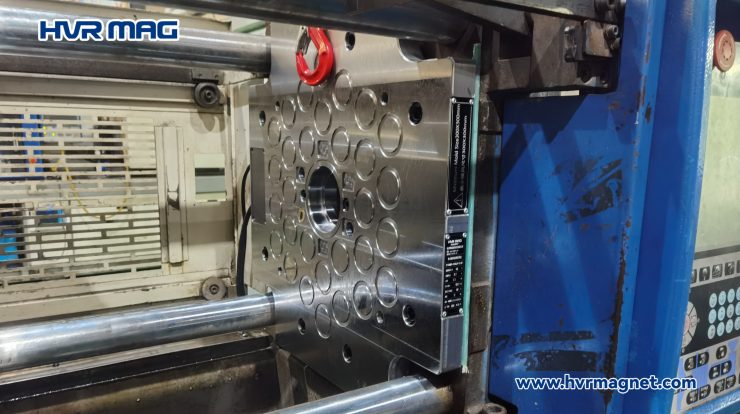

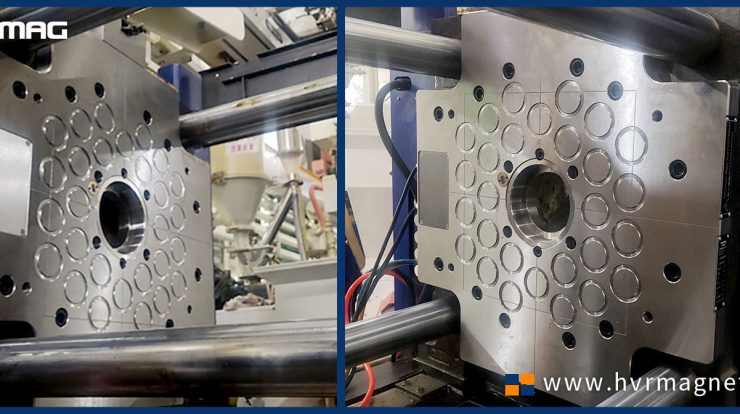

According to the ways of injection molds to be fastened, it can be divided into 2 types: horizontal or vertical machine. The majority of machines are horizontally oriented, but vertical machines are used in some niche applications such as insert molding, allowing the machine to take advantage of gravity. Some vertical machines also do not require the mold to be fastened. There are many ways to fasten the tools to the platens, the most common being manual clamps (both halves are bolted to the platens); however, hydraulic clamps (chocks are used to hold the tool in place) and magnetic clamps are also used. The magnetic and hydraulic clamps are used where fast tool changes are required.

Different industries and indeed different applications require much different type of injection molding machines.

Types of Injection Molding Machines

Hydraulic

Mechanical

Electric

Hybrid

Hydraulic

The oldest and most popular injection machine, it can be used for a variety of purposes and applications. Available in different sizes, hydraulic machines are ideal for performing repeated tasks with fair degree of accuracy. They offer attractive price/performance ratio with range of equipment alternatives to meet specific application and energy requirements. – offer high clamping force that is needed for big part production.

Mechanical

Mechanical type machines use the toggle system for building up tonnage on the clamp side of the machine. Tonnage is required on all machines so that the clamp side of the machine does not open (i.e. tool half mounted on the platen) due to the injection pressure. If the tool half opens up it will create flash in the plastic product.

Electric

Also known as electric machine terminologies (EMT), reduces operation costs and are ideal for producing high-end injection moulded parts in large volumes. Quieter, faster and more accurate, electric presses are also considered to be more environment friendly than hydraulic machines. – are perfect for short injection times and provide the best production cleanliness.

Hybrid

Hybrid machines are know for powerhouse performance in thermoplastics processing. As the name suggests, these machines combine the electric power and precision of electric machine with power and dynamics of hydraulic machines for ultimate performance. – have excellent energy efficiency and give you more freedom for innovative mold design.

From above mentioned, we gained a basic knowledge on injection molding machine. With the growing market for rigid plastic packaging, the demand for IMMs from the packaging industry is increasing.

Learn more about mold change for plastic injection molding machine, feel free to leave us a comment or welcome to visit our website:www.magneticplaten.com