Recommendation on How to Clean and Maintain Magnetic Platen

Magnetic platen is used as mold clamping system in injection molding process. The system allows for precise and uniform clamping of molds, offering the advantages of quick mold changeover. Cleaning…

Injection Molding for Medical Devices: Keep Clean with Magnetic Platen

Injection molding is a widely employed manufacturing process for producing plastic components, and it is well-suited for the production of medical devices due to its ability to provide high precision,…

How Do Magnetic Platens Work Under High Temperature?

Magnetic clamping system has emerged as a useful tool to enhance efficiency and accuracy in injection molding process. This system comprises two sets of electro permanent magnetic platens, with one…

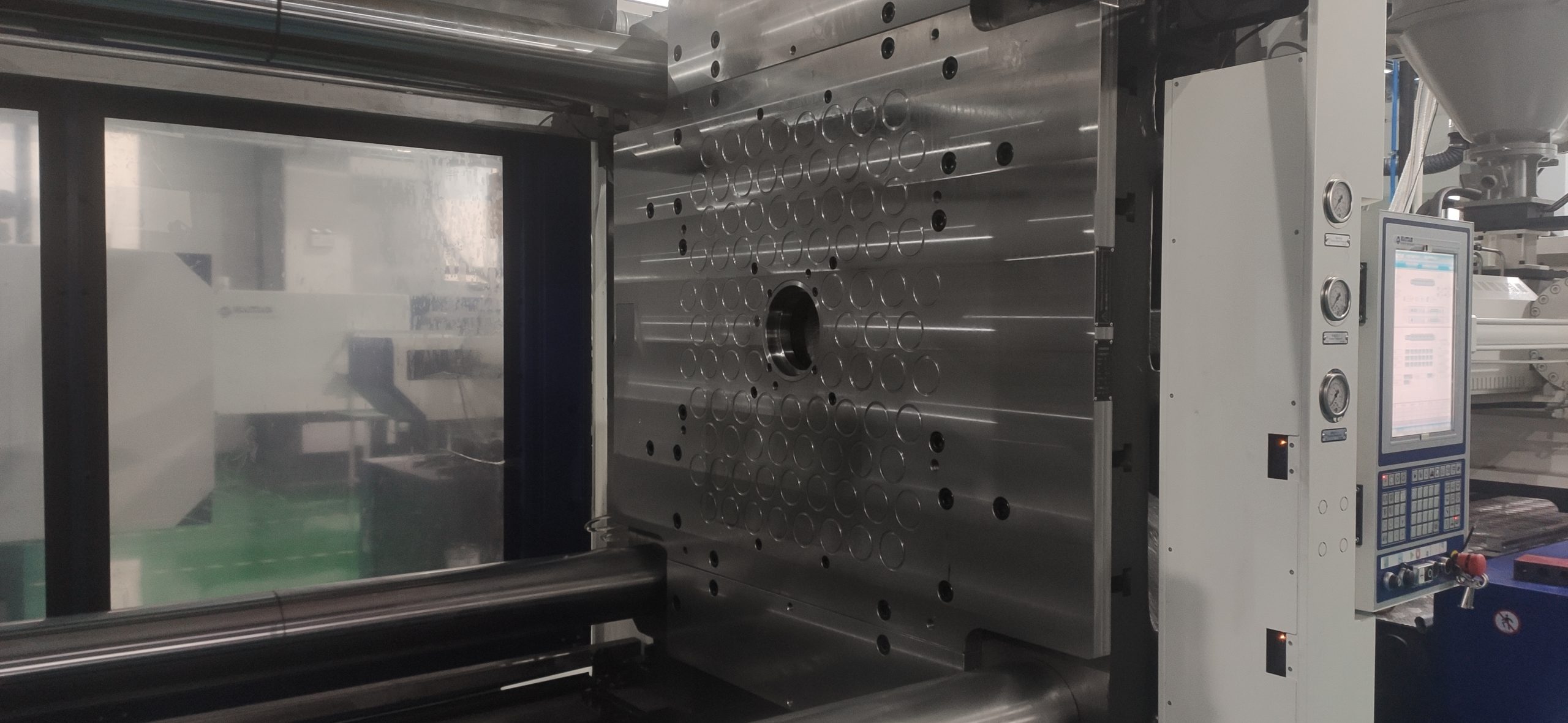

Types of Mold Clamping for Injection Molding Machine

When it comes to injection molding machines, the clamping mechanism plays a crucial role in securely holding the mold during the injection process. Three commonly used clamping methods are hydraulic…

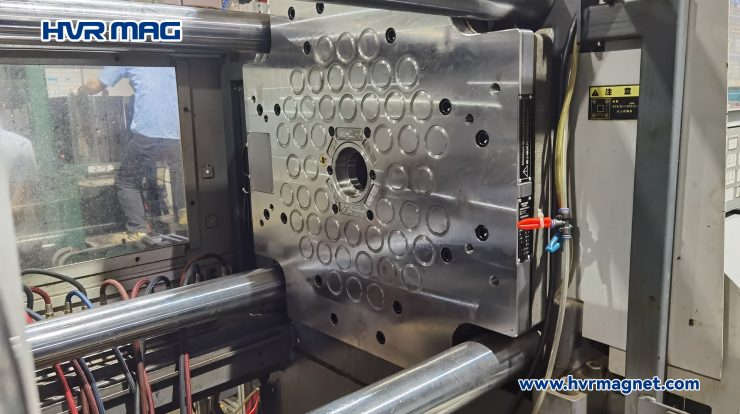

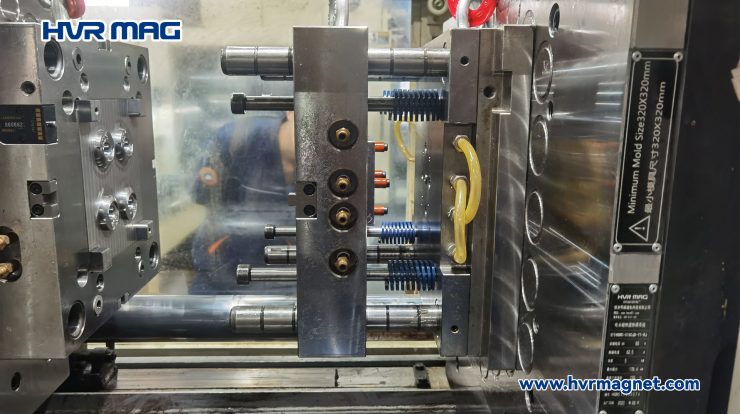

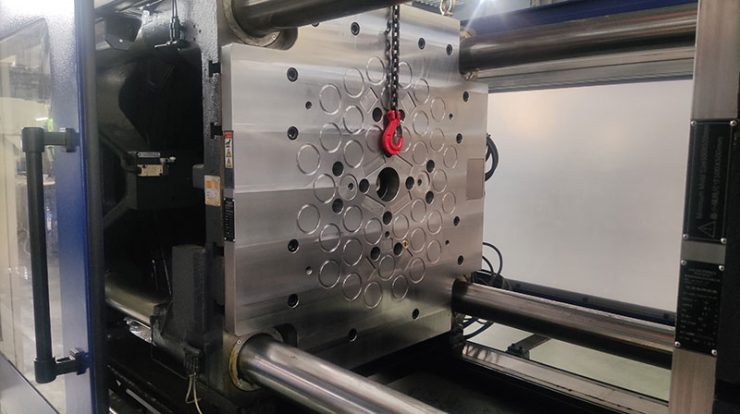

Mold Setting Procedure With Magnetic Mold Clamping System

Mold setting procedure can be fast and simple with magnetic mould clamping system. These are dvantages of the magnetic mold clamping system

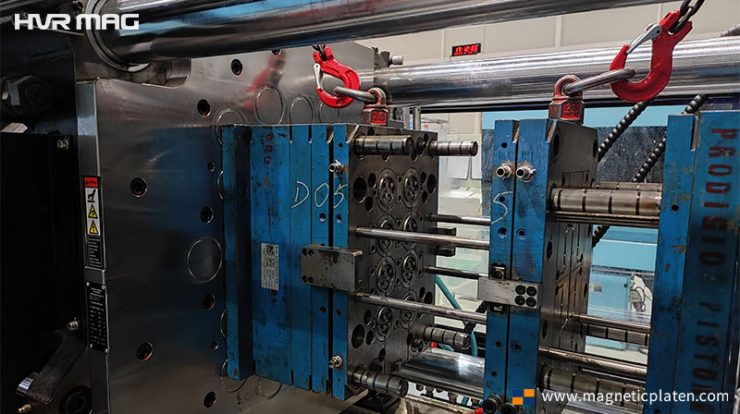

SMED with Magnetic Clamping Devices

Mould or die change is important in injection moulding industry, magnetic clamping devices can help you achieve Single-Minute Exchange of Die

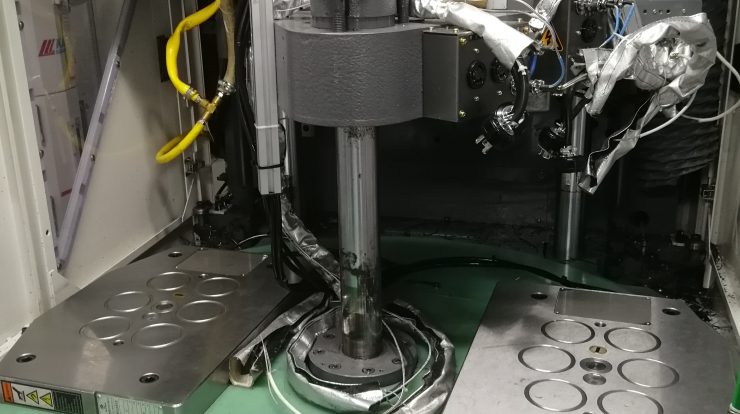

Magnetic Mold Clamping Solution for Vertical Injection Molding Machine

Today I’d like to share with you this application case of small tonnage magnetic mold clamping solution for vertical injection molding machine.

Factors to Consider When Designing the Mold Clamping Force of Magnetic Platens

Magnetic mold clamping system supplier, HVR MAG explains the design factors of the mold clamping force of magnetic platens. Before getting straight to the point, we need to learn about the mold…