Magnetic Clamping Systems for Two-Color Molding Machine

A two-color injection molding machine is specifically designed to produce molded parts using two different colors or materials in a single injection molding cycle. This type of machine has the…

Injection Molding for Medical Devices: Keep Clean with Magnetic Platen

Injection molding is a widely employed manufacturing process for producing plastic components, and it is well-suited for the production of medical devices due to its ability to provide high precision,…

Magnetic Platen: Making Injection Molding More Eco-Friendly

Injection molding machines consume a considerable amount of energy during operation. Implementing energy-efficient equipment, optimizing production processes, and using energy-saving technologies can significantly reduce the energy consumption associated with injection…

How Do Magnetic Platens Work Under High Temperature?

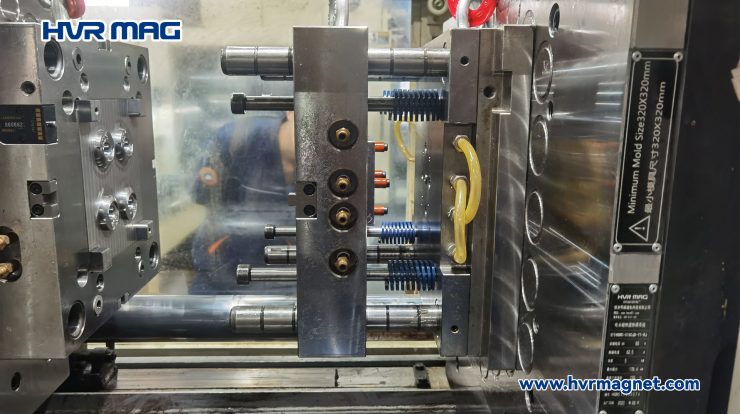

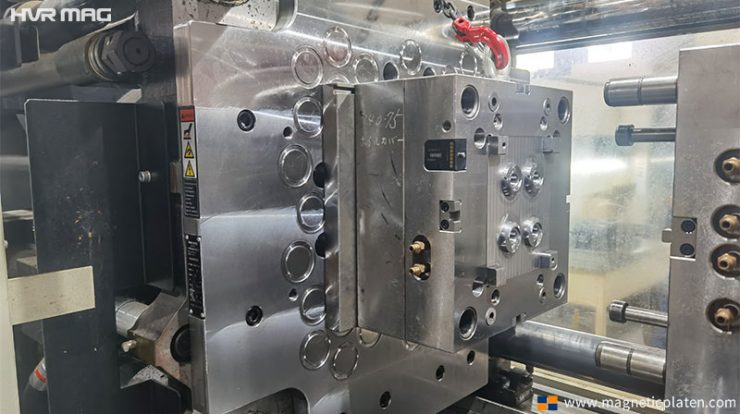

Magnetic clamping system has emerged as a useful tool to enhance efficiency and accuracy in injection molding process. This system comprises two sets of electro permanent magnetic platens, with one…

Understand How Injection Molding Machine Uses Magnetic Clamping System

Magnetic clamping system is essential in the injection molding industry, offering numerous benefits despite certain operational challenges. If your company has not yet adopted a magnetic clamping system, it is…

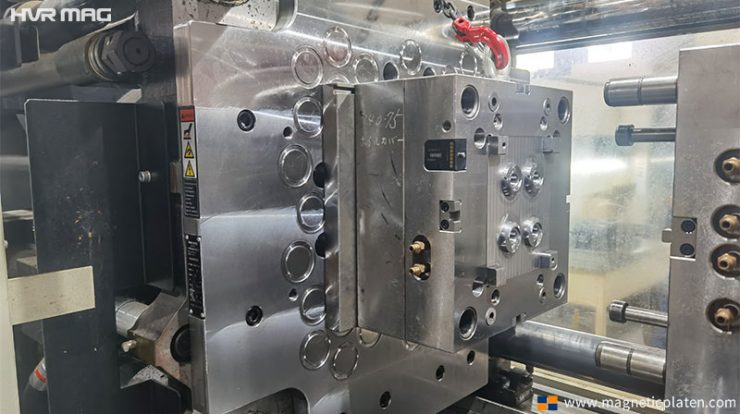

Types of Mold Clamping for Injection Molding Machine

When it comes to injection molding machines, the clamping mechanism plays a crucial role in securely holding the mold during the injection process. Three commonly used clamping methods are hydraulic…

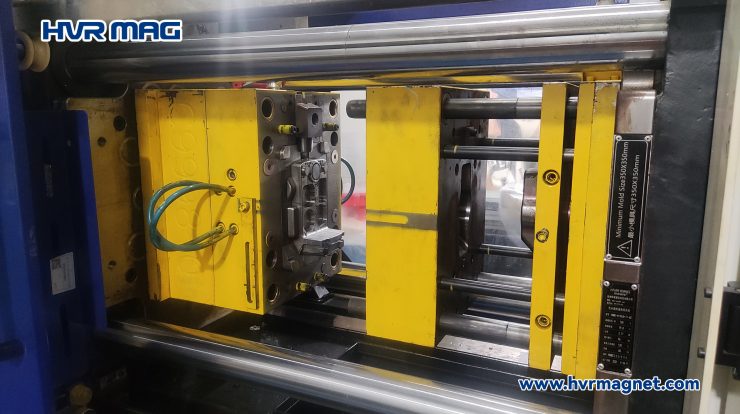

Magnetic Templates for Injection Mould Clamping

Injection mould clamping plays a crucial role in the manufacturing industry, ensuring precise and secure positioning of moulds during the production process. To enhance efficiency and accuracy in this operation,…

How to Reduce Mould Change Time with Magnetic Plates

Efficient mold changeovers are critical in industries. How to reduce mould change time with magnetic mold change systems?

Will Clamping Method Affect the Quality of Product?

Plastic injection molding is a highly versatile process to produce complex shapes and parts with a high degree of accuracy and consistency. Injection molding machines have varies of size and…

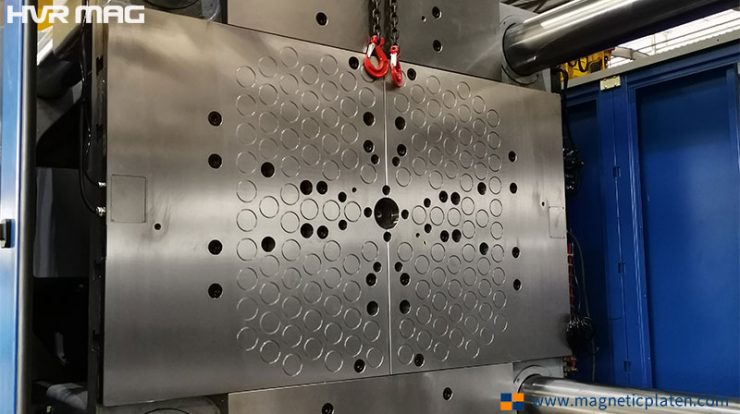

Proper Maintenance Tips for Magnetic Templates in HQMC

Magnetic templates play a crucial role in quick mold change systems, ensuring efficient and precise mold positioning. To maximize their lifespan and performance, proper maintenance is essential. In this blog, we will provide valuable tips on how to properly maintain magnetic templates in quick mold change systems.