What Is Tonnage in Injection Molding and How Is It Calculated?

What is tonnage in injection molding and how to calculate it – are things we need to figure out before deciding the right tonnage of IMM for your process.

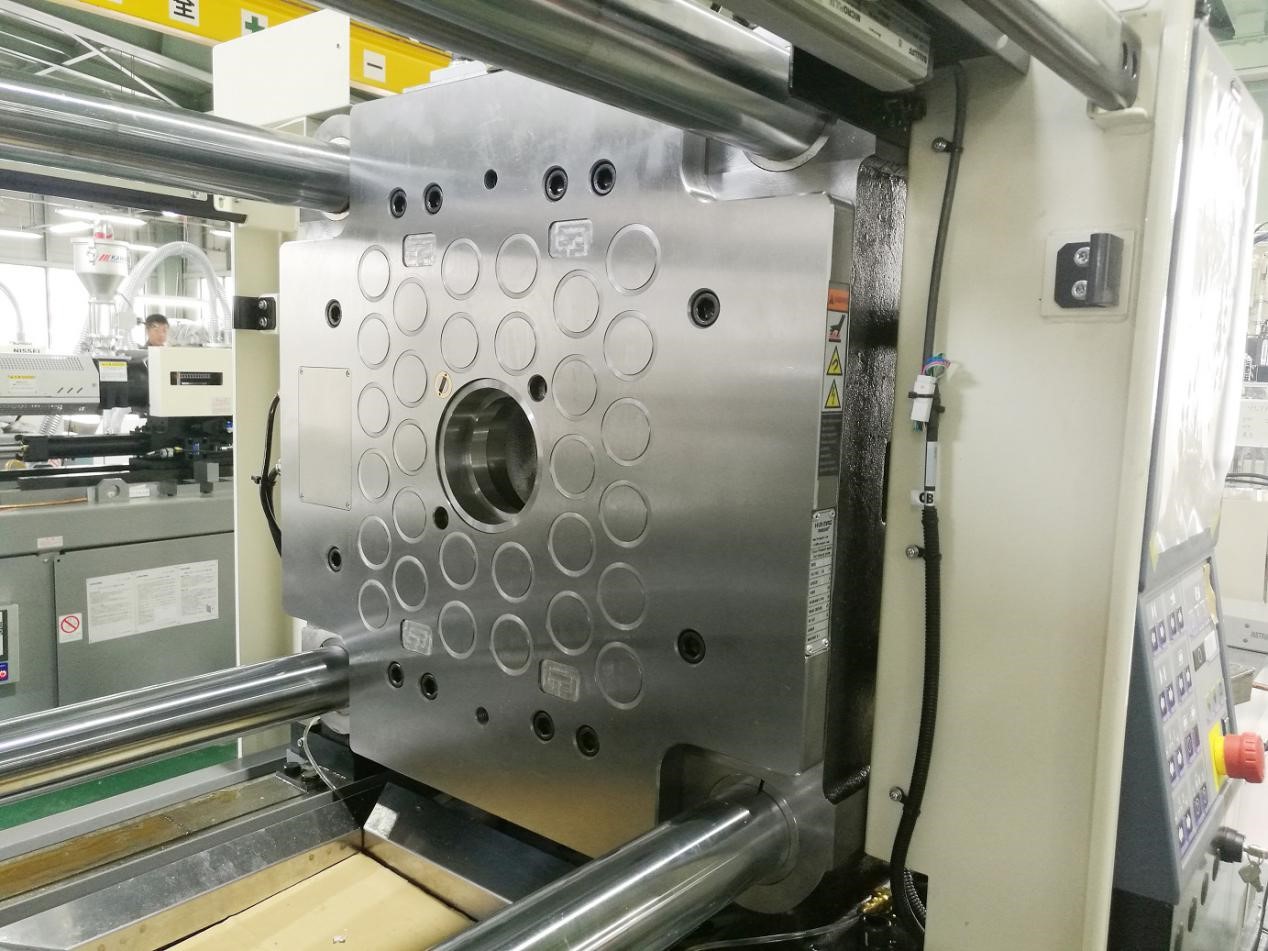

Operational Conditions for HVR MAG Quick Mold Change System

Learn about the operational conditions of HVR MAG quick mold change system for injection molding machines, can do more good to your machine and the molding process.

An Installation Guide to Quick Mold Change System

A guide to the things that should be noticed and prepared before starting the installation of HVR MAG’s quick mold change system, could be beneficial to your injection molding machine.

Staubli Magnetic Mold Clamping System VS HVR MAG Magnetic Mold Clamping System

Comparison of magnetic mold clamping system for injection molding from Staubli and HVR MAG, the latter provides a more versatile range of mold clamp applications.

Comparison of Mold Clamping Systems for Injection Molding – Mechanical, Hydraulic, Magnetic

Understanding the basic features of mold clamping systems for injection molding – mechanical, hydraulic, magnetic, can help you choose the proper quick mold clamping system that best suits your machine to gain maximized productivity | HVR MAG

8 Safety Attributes of HVR MAG Quick Mold Change System

Utilizing magnetic clamping technology in providing magnetic mold clamping solutions – quick mold change system, for plastic injection molding machine, HVR MAG helps make the mold changeover more efficient and cost-effective.

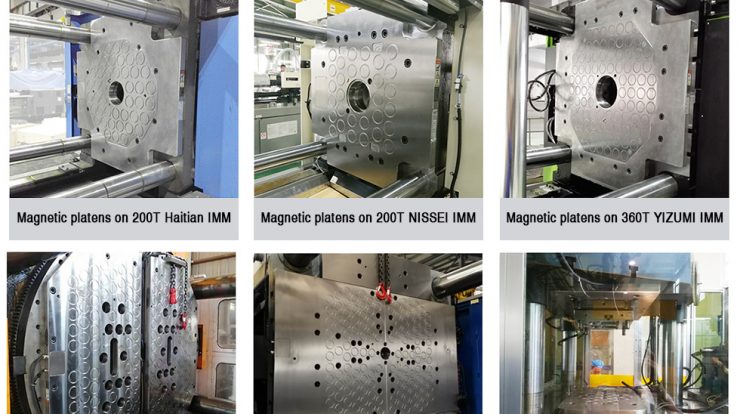

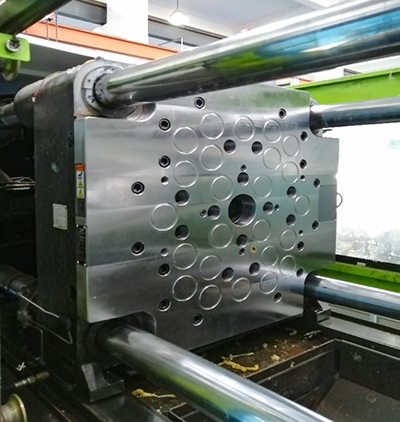

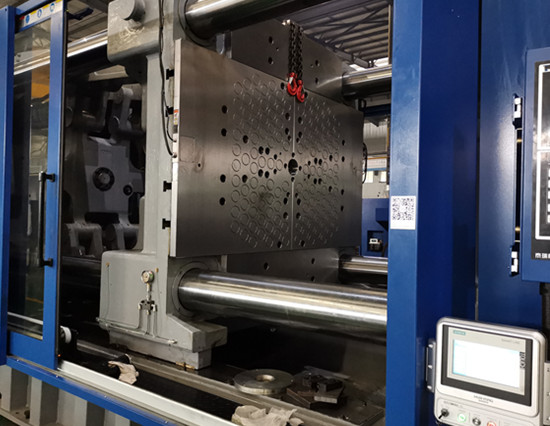

Application of the magnetic quick mold change system

Magnetic quick mold change technology originated in Japan and was initially applied to automobile manufacturers to achieve magnetic quick mold change. In the 1980s, China began to develop a magnetic…

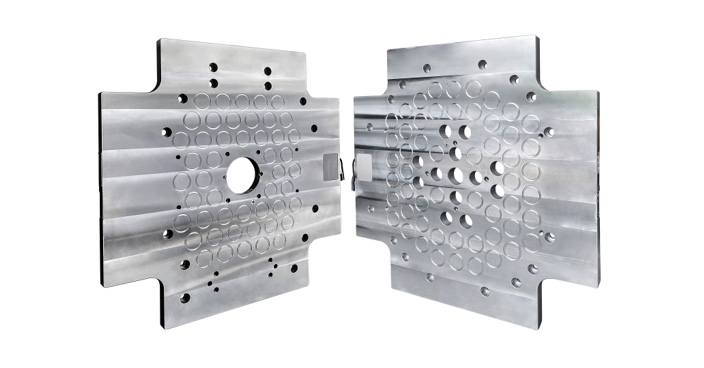

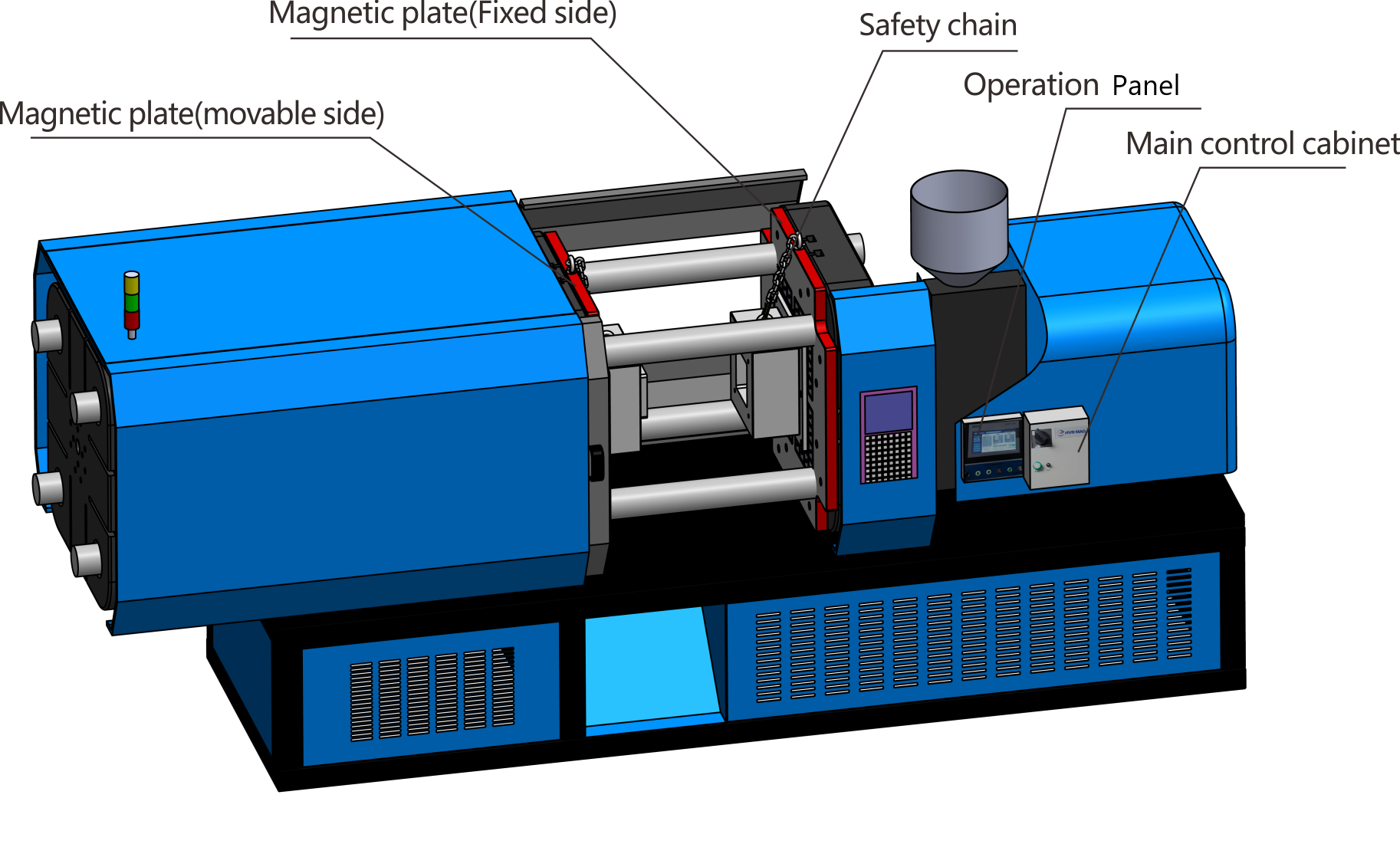

HQMC——Magnetic Quick Mold Change System For Injection Molding Machine

In recent years, the entire plastics industry has shown the following characteristics: the ageing of mold-changers, high labor intensity and high risks, and the reluctance of young people to engage…