When we think of mould clamping system, we usually associate them with conventional injection moulding machines. But in fact HVR’s magnetic mould clamping system is already in use on two-colour injection moulding machines. The two types of injection moulding machines are different in construction. Accordingly, the mould and the corresponding clamping system must be specially designed.

Structure of two-colour injection moulding machines

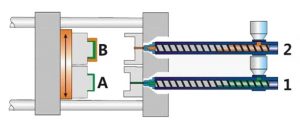

Let’s look at the difference between a two-colour injection moulding machine and a conventional machine. A conventional injection moulding machine has only one hopper and one injection unit. A two-colour injection moulding machine consists of two injection units with identical design and specifications. In a two-colour machine, two injections are required in a production cycle. After the first injection is completed, the mould on moving template must be rotated 180°. Then the mould closed again to complete the second injection. As the two-colour injection process is different from the normal injection process, the material used in the two-colour injection process requires higher melt temperature parameters to ensure that the material does not harden before the filling is complete. Secondly, a higher injection pressure is required to overcome the high resistance to flow of the melt in the mould and to ensure smooth filling.

Design principle of mould clamping system for two-colour injection moulding machines

And because of the structural characteristics of two-colour injection moulding machines, the mould and its clamping device also require special design. Two-colour injection mould runners are longer and more complex, with higher resistance to the flow of the injected melt. The back plate of the moving side in a two-colour injection moulding machine usually has a turntable or swivel mechanism. This provide a 180°reciprocal rotation function. The mould clamping system should therefore also be designed for easy rotation on the moving side of the machine.

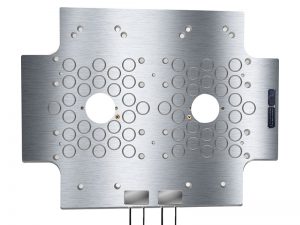

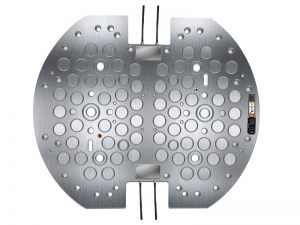

HVR MAG has developed a magnetic mould clamping system for two-colour injection moulding machines. It consists of two magnetic plates, one for the fixed side and one for the moving side. A control box and a control panel are also included. The static magnetic plate has two positioning holes according to the size of the injection unit. It is adapted to the shape of the static template of the injection moulding machine and is square. The moving magnetic plate is rounded for easy rotation.

The HVR MAG mould clamping system offers the following advantages

- Two all-steel flat magnetic plates fit perfectly on the back plate of the injection moulding machine. There is no obstruction in the area where the mould enters the injection moulding machine. Nor does it block the interface at the side of the mould.

- The back of the mould is completely parallel to the magnetic template and the force is uniform.

- The magnetic pull of the electro-permanent magnet is strong (16kg per square centimetre). No electricity is required to maintain the magnetism. Energy saving and no risk of overheating.

- There are no external wires or parts on the magnetic formwork other than the power cord. As long as a sufficient length of power cable is reserved on the moving plate, it can be rotated at will.

- The clamping method is simple and convenient. Simply magnetise the magnetic template for 0.2-2 seconds to complete mould clamping. This allows you to achieve a 3 minutes quick mould change.

- The magnetic plate is equipped with temperature detection, misalignment detection and magnetic flux detection devices. You can monitor the status of the mould at any time to ensure the safety of the injection moulding process.

There is another detail to consider when selecting a mould clamping system for a two-colour injection moulding machine. Two-colour injection moulding machines have more complex mould and may require a larger opening stroke. If your injection moulding machine already has a very narrow opening stroke, a special customised solution may be required.

If you need a mold clamping solution, please contact us at:export@hvrmagnet.com