We are thrilled to announce the commencement of construction for HVR MAG’s new state-of-the-art manufacturing plant....

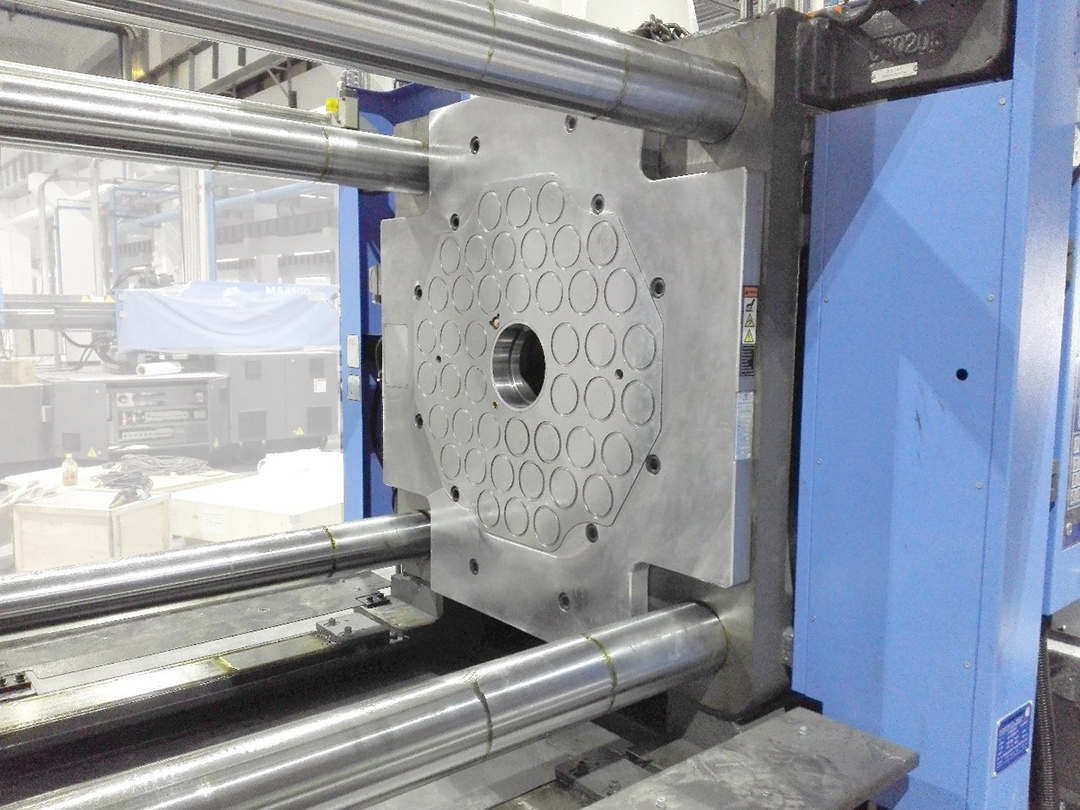

In injection molding, why does mold platen thickness matter? We know lots of injection molding manufacturers hope the mold platens to be thin. What is the connection between mold platen thickness and opening stroke? ..

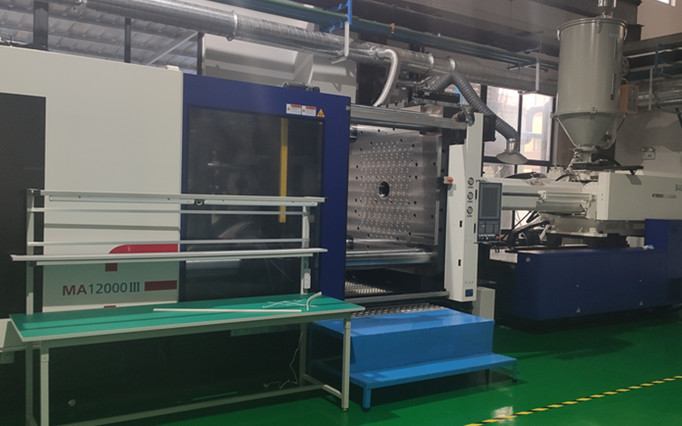

With the increasing competition in the market, plastic products are being renewed more and more quickly, with more and more coexisting varieties, the production of multiple varieties, small and medium batches and mixed flow just-in-time production is becoming mainstream. Injection molding is the most versatile way to produce parts and products. It's fast, works with a variety of plastics, and can result in a prototype or final product that is both durable and highly detailed. But the process is complex and riddled with challenges. HVR has a perfect solution to help you optimize the productivity of your injection molding machine. ..

The world is full of plastics. Whether you realize it, practically everything you see and use daily is entirely or partly plastic material. Your house, car and many other essential products utilize plastic material to make your life easier. Today, let's talk about their exact used industries and precise applications.How to imrpove the efficiency? ...

With the development of society, one of the most repeated industry buzzwords is “green”. One way to take advantage of the green wave is to incorporate quick mould change systems into your facilities. Quick mould change systems can reduce waste and increase mould change efficiency. Safety and improved press utilization are additional benefits. The changeover time will be significantly reduced when using quick mould change systems. In 3 minutes, the mould can be moved either from the operator side or the nonoperator side of the moulding machine. ...